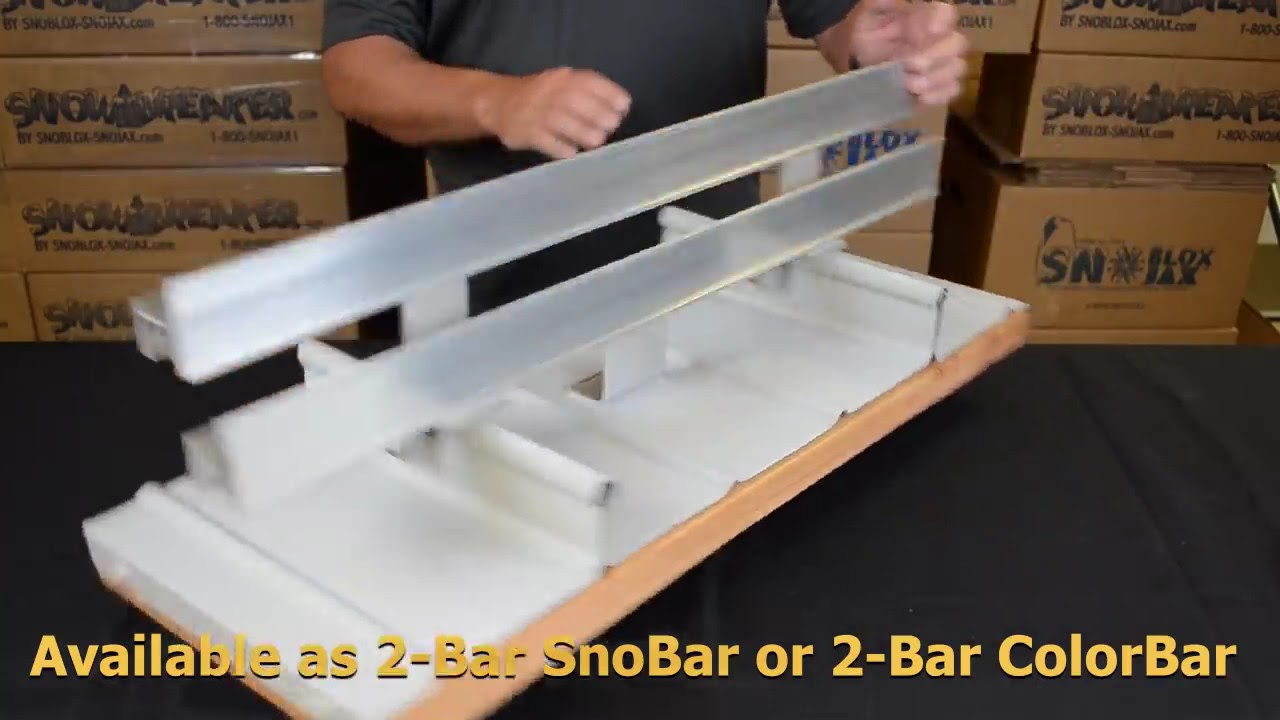

Two Bar ColorBar is our heavy-duty aluminum snow rail system that features two super strong extruded aluminum ColorBars and Double Bar Brackets.

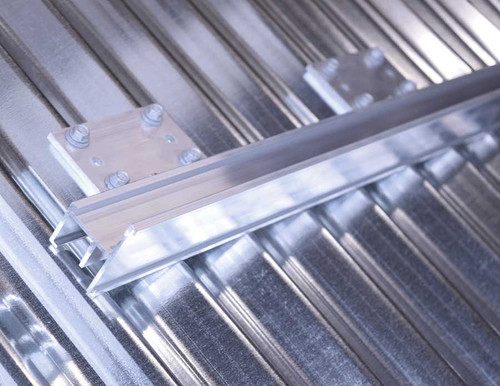

The double bar ColorBar snow rail system is safely and securely fastened to a standing seam panel with the patented aluminum RCT RoofClamp using stainless steel cup-tipped set screws. The Two Bar ColorBar features top-loading upper and lower bars for fast installation. Channels in the face if the bar can accept optional 2” metal color strips. Two-bar ColorBar systems can be designed for most standing seam roof systems. Mill finish 6-foot kits are in stock and shipped fast via ground shipping. Large and custom orders are usually shipped at 12-foot lengths and packed in crates that are shipped via LTL freight. Sample Bar Kits for submittal purposes are available for purchase.

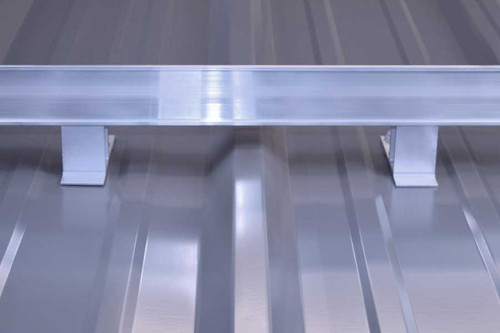

Double Bar ColorBar Snow Rails are Safe for Concealed Fastener Metal Roofs

This product is perfect for standing seam metal roofs with its one-piece aluminum clamp featuring three non-penetrating cup-tipped set screws. This continuous 2-bar rail design runs the length of the roof and ensures no risk of damaging roof seams with screws or holes. The double bar ColorBar prevents rooftop avalanches that can lead to damaged gutters, HVAC units, cars, patios, and even injuries.

Double Bar ColorBar Snow Rails Feature:

-

Made in America

-

Laboratory and Field-Tested for Many Years

-

Year-Round Installation

-

Both Bars Top Load For Easy installation

-

High-Grade Mill 6061 T-6 Aluminum.

-

Accepts a Two-Inch Color Strip in the Face of the Bar.

-

Powder Coated Option to Match the Roof is Available.

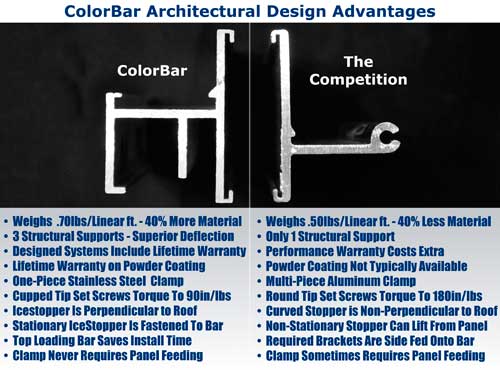

Two Bar ColorBar Snow Rails Features Unmatched Strength and Durability

Double Bar ColorBar features an extruded aluminum bar and offers unbeatable strength and durability. The product also features super strong "cup tipped" stainless steel screws, not slippery "round nose" screws. The strength of this product has been proven in both laboratory and field testing.

Easy Installation

Exclusive low torque roof clamps combined with top loading brackets make this the industry's fastest bar system to install. Fewer parts mean less labor!

Two Bar ColorBar Includes Custom Design Options

We will provide a free custom design and quote for your SnoBar system. Begin the process by submitting the Quote Request Form or call us at 1-800-SNOJAX-1 (800-766-5291) with any questions.

Two ColorBar Submittal Documents:

-

Two Bar SnoBar ColorBar Specification Sheet

-

Two Bar Colorbar Cut Sheet

-

Snobar/ColorBarRCB-2Clamp Compatibility Chart

-

Price Quote Request

-

Installation Instructions

-

Warranty

-

Standing Seam ColorBar Spacing Guide

2 Bar ColorBar Important Disclaimer:

This snow retention system is not designed to be installed in isolated areas such as just over doorways, stack pipes, chimneys, or partial roof sections. Upper roofs, if any, must not be allowed to shed snow and ice onto lower roof areas where this product is being used. All upper roof areas must have a snow retention system in place before using this product on lower roof areas. Always obtain a manufacturer's quantity and spacing recommendation before purchasing and installing this product. If this system is not used as per the manufacturer's recommendation, severe roof panel damage, personal injury, and/or death may occur.

About SnoBar-ColorBar

Don Drew and Dick Riddell invented SnoBar in 1992, making it the original standing seam-mounted snow rail. It was unique enough to earn a patent in 1993. Jim Huff installed the initial version, named Sno Horse, at the Denver International Airport in 1992. Jim Huff devised a way to make an aluminum bar with a channel to slide a piece of metal into the face plate based on a concept from name plates commonly found on office desks. The Sno Horse product later became known as the ColorBar, which features quick installation with a patented drop-in clamp to attach the bar. Roof clamps to attach the bar are available in stainless steel or aluminum. Standing seam metal roofs have utilized the SnoBar system longer than any other snow rail product. There is a SnoBar and ColorBar snow retention system for every sloped roof prone to snow slides. Both snow rails can be powder-coated to match your metal roof.