Spacing For SnoBar on Standing Seam Metal Roofs

SnoBar For Standing Seam Spacing Guidelines

In parts of the world that receive winter precipitation, snow and ice on glossy coated metal roofing can create an extremely dangerous avalanche condition. A properly installed snow guard system can mitigate this condition. Our approach to proper placement involves an overall spacing throughout the entire roof area to keep snow and ice from shifting initially. Once frozen precipitation loses its grip on a metal roof and begins a down-hill slide, everything in its path will be destroyed. A single row of guards placed along the eave or gutter edge of the roof is not always enough protection against this dangerous condition. An evenly distributed snow load will preserve the long-term integrity of the actual structure, metal roof and snow retention system. Isolating snow guards on partial roof sections such as just over doorways or roof vents is not recommended. Select your pitch below to get a general spacing guideline. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. This page should only be used only as a quick reference guide for estimating snow guard quantities and placement on roofs with up to 45 PSF ground snow load. Always consult with an architect or engineer for recommended snow guard placement for your project. This spacing guideline does not account for snow shadows, drifting or unseasonable conditions. If your ground snow load exceeds 45PSF please fill out our Quote Request Form for the heavy duty ColorBar systems.

Please Pick Your Roof Pitch Below

| 1/12 Roof Pitch | 2/12 - 3/12 Pitch | 4/12 - 6/12 Pitch | 7/12 - 9/12 Pitch | 10/12 - 12/12 Pitch |

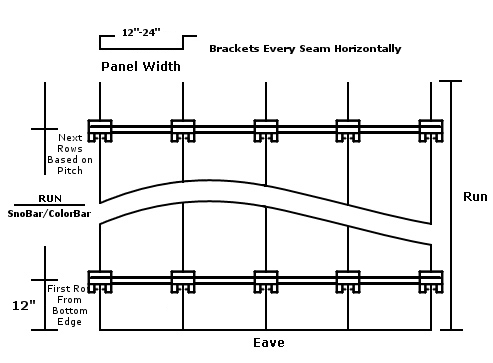

1/12 Roof Pitch

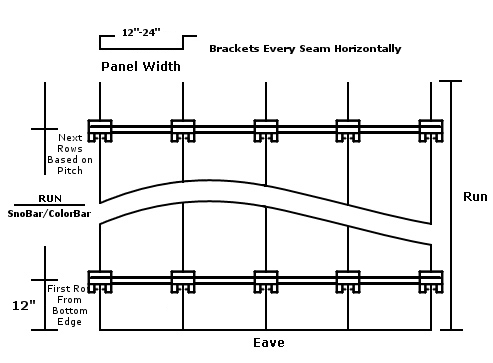

Panel: Valleys 12 to 24 inches.

IceStoppers: 12 inches to 17 inches needs 1 IceStopper Per Panel - 18 inches to 24 inches needs 2 IceStoppers Per Panel

Pitch: 1/12

Spacing: Every 50 feet up the roof.

Isolated Roof Areas: Never use SnoBar in isolated roof areas such as just over doorways etc.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a supported overhang, place the SnoBar using one clamp per seam, across the entire roof area. Go up the roof every 50 feet and run another row of SnoBar across the entire roof. Do not exceed 50 feet vertically between rows of bar. For Example: if your roof sheets are 100 feet long, your roof would require a row at approximately1 foot from the bottom and at 50 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. All upper roof areas must have a snow retention installed before installing SnoBar on a lower roof. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. Never isolate areas of SnoBar such as just over doorways or vent pipes.

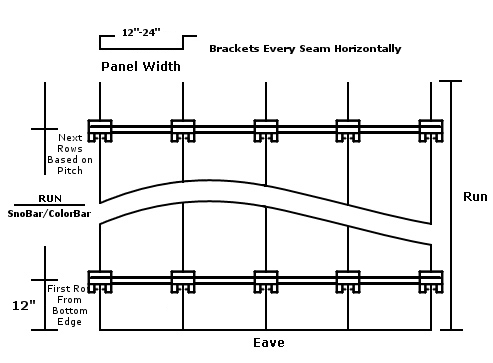

2/12 - 3/12 Roof Pitch

Panel: Valleys 12 to 24 inches.

IceStoppers: 12 inches to 17 inches needs 1 IceStopper Per Panel - 18 inches to 24 inches needs 2 IceStoppers Per Panel

Pitch: 2/12 to 3/12

Spacing: Every 18 feet up the roof.

Isolated Roof Areas: Never use SnoBar in isolated roof areas such as just over doorways etc.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a supported overhang, place the SnoBar using one clamp per seam, across the entire roof area. Go up the roof every 18 feet and run another row of SnoBar across the entire roof. Do not exceed 18 feet vertically between rows of bar. For Example: if your roof sheets are 36 feet long, your roof would require a row at approximately1 foot from the bottom and at 18 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. All upper roof areas must have a snow retention installed before installing SnoBar on a lower roof. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. Never isolate areas of SnoBar such as just over doorways or vent pipes.

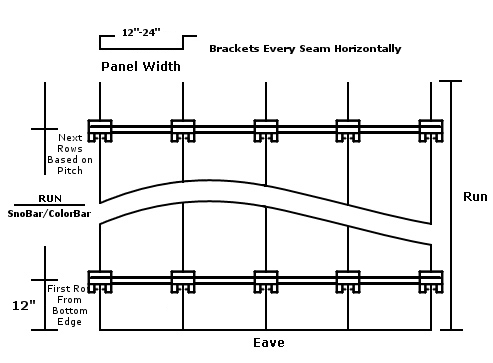

4/12 - 6/12 Roof Pitch

Panel: Valleys 12 to 24 inches.

IceStoppers: 12 inches to 17 inches needs 1 IceStopper Per Panel - 18 inches to 24 inches needs 2 IceStoppers Per Panel

Pitch: 4/12 to 6/12

Spacing: Every 10 feet up the roof.

Isolated Roof Areas: Never use SnoBar in isolated roof areas such as just over doorways etc.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a supported overhang, place the SnoBar using one clamp per seam, across the entire roof area. Go up the roof every 10 feet and run another row of SnoBar across the entire roof. Do not exceed 10 feet vertically between rows of bar. For Example: if your roof sheets are 20 feet long, your roof would require a row at approximately1 foot from the bottom and at 10 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. All upper roof areas must have a snow retention installed before installing SnoBar on a lower roof. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. Never isolate areas of SnoBar such as just over doorways or vent pipes.

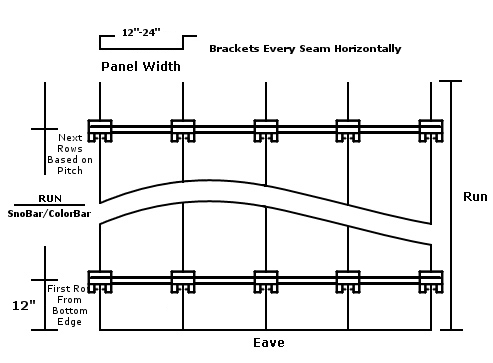

7/12 - 9/12 Roof Pitch

Panel: Valleys 12 to 24 inches.

IceStoppers: 12 inches to 17 inches needs 1 IceStopper Per Panel - 18 inches to 24 inches needs 2 IceStoppers Per Panel

Pitch: 7/12 to 9/12

Spacing: Every 7.5 feet up the roof.

Isolated Roof Areas: Never use SnoBar in isolated roof areas such as just over doorways etc.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a supported overhang, place the SnoBar using one clamp per seam, across the entire roof area. Go up the roof every 7.5 feet and run another row of SnoBar across the entire roof. Do not exceed 7.5 feet vertically between rows of bar. For Example: if your roof sheets are 15 feet long, your roof would require a row at approximately1 foot from the bottom and at 7.5 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. All upper roof areas must have a snow retention installed before installing SnoBar on a lower roof. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. Never isolate areas of SnoBar such as just over doorways or vent pipes.

10/12 - 12/12 Roof Pitch

Panel: Valleys 12 to 24 inches.

IceStoppers: 12 inches to 17 inches needs 1 IceStopper Per Panel - 18 inches to 24 inches needs 2 IceStoppers Per Panel

Pitch: 10/12 to 12/12

Spacing: Every 6 feet up the roof.

Isolated Roof Areas: Never use SnoBar in isolated roof areas such as just over doorways etc.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a supported overhang, place the SnoBar using one clamp per seam, across the entire roof area. Go up the roof every 6 feet and run another row of SnoBar across the entire roof. Do not exceed 6 feet vertically between rows of bar. For Example: if your roof sheets are 12 feet long, your roof would require a row at approximately1 foot from the bottom and at 6 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. All upper roof areas must have a snow retention installed before installing SnoBar on a lower roof. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer maximum placement guidelines. Never isolate areas of SnoBar such as just over doorways or vent pipes.

Disclaimer

This page may be used only for the purpose of developing plans, specifications and/or approval drawings for construction projects utilizing only IceBlox, Inc. manufactured or distributed products and components. It is to be used only as a quick reference for estimating snow guard quantities and placement on roofs with less than 45 PSF ground snow load.

IceBlox Inc., d.b.a SnoBlox-Snojax, referred to hereafter as IceBlox, Inc., or any subsidiary brands or companies, is not responsible for estimates or purchases resulting from the erroneous or improper use of this page or snowguardspacingtool.com.

The user shall determine the suitability of the product for its intended use and assumes all risks of its use or handling. In regards to spacing guidelines, quotations and or layouts, Iceblox, Inc. will not be held liable for incorrect material quantities not recommended on snowguardspacingtool.com and/or SnoBlox-Snojax.com

Spacing For SnoBar Frequently Asked Questions (FAQs)

A 1" x 1" square hollow tube of Gator Shield-coated galvanized steel makes up the SnoBar system. The extruded 6061-T6 aluminum bar used in the ColorBar system can accommodate a color strip. Both systems are available for online purchase, in mill finish, or by phone in powder-coated finish. The superior strength of the ColorBar allows it to span panels wider than 24".

Standing seam rail systems have an optional attachment called IceStoppers. These essential accessories prevent low-lying snow and ice from sliding underneath the rails. They secure to the back of the bar without panel penetration. Although they are optional, we strongly recommend IceStoppers over locations where pedestrians or vehicles are present. Previously installed rail systems can have IceStoppers retrofitted.

SnoBar and ColorBar devices are compatible with almost any style of sloped roofing. We offer snow rail systems for a variety of roofing types, including Standing Seam, Screw Down, PBR, Wavy Corrugated, Shingle, Membrane, TPO, and Slate.

You may order mill finish, 6-foot SnoBar, and ColorBar kits on our website. We also have 12-foot bars shipped LTL in wooden crates when higher linear footage volumes are necessary or when a bespoke powder-coated finish is wanted. Our technicians are ready to provide our customers with a price for these systems. Turnaround periods for price quotes are typically 24 to 48 hours.

A correctly designed snow rail system typically includes multiple rows up the roof slope to distribute weight evenly. Variations in panel types, seam spacing, roof slopes, snow loads, and attachment methods significantly impact the layout of a project. Please refer to our spacing charts or fill out the SnoBar or ColorBar Quote Request Forms for more details.

The SnoBar system features black plastic endcaps that seal the ends of the bars. The caps are made from low-density polyethylene and have a service temperature of 150° F (66° C). These end caps provide the bar with a clean, finished look while preventing outside elements, insects, and rodents from getting inside. Two caps are required per bar and help hide bare cut edges on painted or powder-coated systems when field cuts are necessary.

SNOBAR COLORBAR PRICING

Price List for 12 foot SnoBar and ColorBar