Spacing For Screw Down SnowCatcher Snow Guards on Exposed Fastener Metal Roofs

Screw Down SnowCatcher Snow Guard Spacing Guidelines

In parts of the world that receive winter precipitation, snow and ice on glossy coated metal roofing can create an extremely dangerous avalanche condition. A properly installed snow guard system can mitigate this condition. Our approach to proper placement involves an overall spacing throughout the entire roof area to keep snow and ice from shifting initially. Once frozen precipitation loses its grip on a metal roof and begins a down-hill slide, everything in its path will be destroyed. A single row of guards placed along the eave or gutter edge of the roof is not always enough protection against this dangerous condition. An evenly distributed snow load will preserve the long-term integrity of the actual structure, metal roof and snow retention system. Isolating snow guards on partial roof sections such as just over doorways or roof vents is not recommended. You can use the snow guard spacing calculator or select your pitch below to get a general spacing guideline. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. This page should only be used only as a quick reference guide for estimating snow guard quantities and placement on roofs with up to 45 PSF ground snow load. Always consult with an architect or engineer for recommended snow guard placement for your project. This spacing guideline does not account for snow shadows, drifting or unseasonable conditions. If your ground snow load exceeds 45PSF please fill out our Quote Request Form for the heavy duty SnoBar/ColorBar systems.

Please Click on Your Roof Pitch Below

| 1/12 - 2/12 Pitch | 3/12 - 4/12 Pitch | 5/12 - 6/12 Pitch | 7/12 - 8/12 Pitch | 9/12 - 12/12 Pitch |

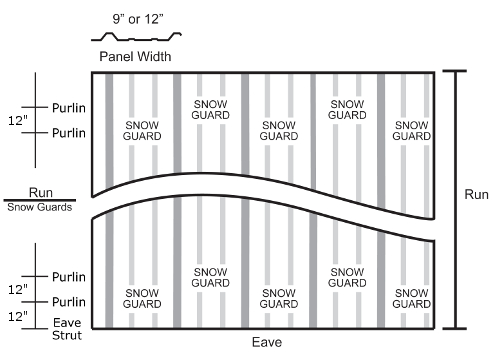

1/2 - 2/12 Roof Pitch

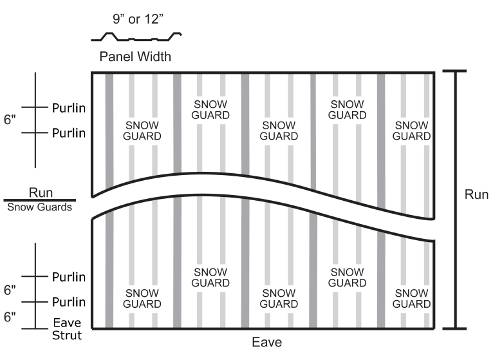

Eave Strut: Horizontal beams that are installed between the roof rafters or trusses and the top plate of the exterior wall.

Panel: Snow guards staggered in every panel flat

Pitch: 1/12 to 2/12 pitch.

Use: Staggered pattern of snow guards every 25 feet going up the roof.

Snow load: Up to 45 PSF ground snow load.

If your metal roof panels are only mounted on top of purlins or firing strips, the snow guards must be screwed into the purlins or firing strips. If your metal panels are placed on decking, make sure your decking is adequate to secure the snow guards. Place your first staggered pattern of snow guards in, every other panel flat, along the Eave Strut (1 foot from the bottom edge on decking). Then move up to the first purlin above the eave strut (2 foot up from the bottom edge on decking) and place a snow guard in the center of each valley, alternating from the row below to create a staggered pattern that spans across the entire roof. Move up the roof every 25 feet and repeat the same staggered pattern of guards across the entire roof. Do not exceed 25 feet vertically between staggered patterns of snow guards. When possible, always attempt to divide the roof areas into equal sections, with equal distance between patterns of snow guards. Please note that our spacing is based on metal panels attached directly to a flat decking surface such as plywood or osb. If your metal roof panels are attached to horizontal purlins (strips of wood that leave an air gap between the roof structure and the panels) then you will need to modify the staggering of the rows to ensure that your fasteners are getting into solid structural wood. Please ensure that your purlins and/or decking material is in good serviceable condition and can withstand the snow loads that will be transferred to it by installing a snow retention system. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. Never isolate areas of snow guards such as just over doorways or vent pipes.

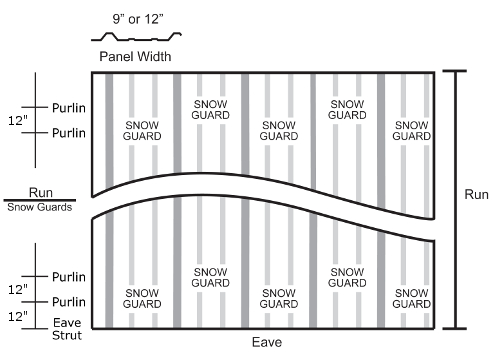

3/12 - 4/12 Roof Pitch

Eave Strut: Horizontal beams that are installed between the roof rafters or trusses and the top plate of the exterior wall.

Panel: Snow guards staggered in every panel flat

Pitch: 3/12 up to 4/12 pitch.

Use: Staggered pattern of snow guards every 20 feet going up the roof.

Snow load: Up to 45 PSF ground snow load.

If your metal roof panels are only mounted on top of purlins or firing strips, the snow guards must be screwed into the purlins or firing strips. If your metal panels are placed on decking, make sure your decking is adequate to secure the snow guards. Place your first staggered pattern of snow guards in, every other panel flat, along the Eave Strut (1 foot from the bottom edge on decking). Then move up to the first purlin above the eave strut (2 foot up from the bottom edge on decking) and place a snow guard in the center of each valley, alternating from the row below to create a staggered pattern that spans across the entire roof. Move up the roof every 20 feet and repeat the same staggered pattern of guards across the entire roof. Do not exceed 20 feet vertically between staggered patterns of snow guards. When possible, always attempt to divide the roof areas into equal sections, with equal distance between patterns of snow guards. It is highly recommended to screw into a purlin or structural support. This spacing recommendation can be slightly adjusted to accommodate locations of the structural support and purlins under the metal roof sheets. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. Never isolate areas of snow guards such as just over doorways or vent pipes.

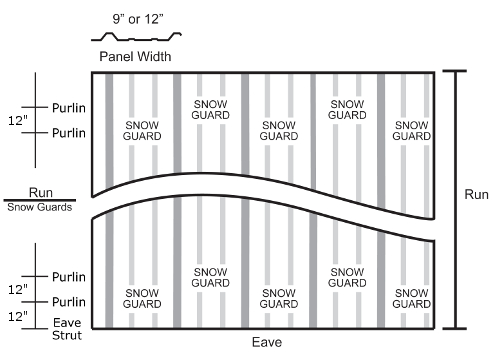

5/12 - 6/12 Roof Pitch

Eave Strut: Horizontal beams that are installed between the roof rafters or trusses and the top plate of the exterior wall.

Panel: Snow guards staggered in every panel flat

Pitch: 5/12 up to 6/12 pitch.

Use: Staggered pattern of snow guards every 10 feet going up the roof.

Snow load: Up to 45 PSF ground snow load.

If your metal roof panels are only mounted on top of purlins or firing strips, the snow guards must be screwed into the purlins or firing strips. If your metal panels are placed on decking, make sure your decking is adequate to secure the snow guards. Place your first staggered pattern of snow guards in, every other panel flat, along the Eave Strut (1 foot from the bottom edge on decking). Then move up to the first purlin above the eave strut (2 foot up from the bottom edge on decking) and place a snow guard in the center of each valley, alternating from the row below to create a staggered pattern that spans across the entire roof. Move up the roof every 10 feet and repeat the same staggered pattern of guards across the entire roof. Do not exceed 10 feet vertically between staggered patterns of snow guards. When possible, always attempt to divide the roof areas into equal sections, with equal distance between patterns of snow guards. It is highly recommended to screw into a purlin or structural support. This spacing recommendation can be slightly adjusted to accommodate locations of the structural support and purlins under the metal roof sheets. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. Never isolate areas of snow guards such as just over doorways or vent pipes.

7/12 - 8/12 Roof Pitch

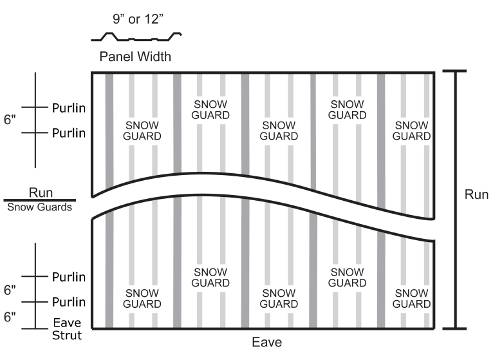

Eave Strut: Horizontal beams that are installed between the roof rafters or trusses and the top plate of the exterior wall.

Panel: Snow guards staggered in every panel flat

Pitch: 7/12 up to 8/12 pitch.

Use: Staggered pattern of snow guards every 6 feet going up the roof.

Snow load: Up to 45 PSF ground snow load.

If your metal roof panels are only mounted on top of purlins or firing strips, the snow guards must be screwed into the purlins or firing strips. If your metal panels are placed on decking, make sure your decking is adequate to secure the snow guards. Place your first staggered pattern of snow guards in, every other panel flat, along the Eave Strut (6" from the bottom edge on decking). Then move up to the first purlin above the eave strut (1 foot up from the bottom edge on decking) and place a snow guard in the center of each valley, alternating from the row below to create a staggered pattern that spans across the entire roof. Move up the roof every 6 feet and repeat the same staggered pattern of guards across the entire roof. Do not exceed 6 feet vertically between staggered patterns of snow guards. When possible, always attempt to divide the roof areas into equal sections, with equal distance between patterns of snow guards. It is highly recommended to screw into a purlin or structural support. This spacing recommendation can be slightly adjusted to accommodate locations of the structural support and purlins under the metal roof sheets. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. Never isolate areas of snow guards such as just over doorways or vent pipes.

9/12 - 12/12 Roof Pitch

Eave Strut: Horizontal beams that are installed between the roof rafters or trusses and the top plate of the exterior wall.

Panel: Snow guards staggered in every panel flat

Pitch: 9/12 up to 12/12 pitch.

Use: Staggered pattern of snow guards every 5 feet going up the roof.

Snow load: Up to 45 PSF ground snow load.

If your metal roof panels are only mounted on top of purlins or firing strips, the snow guards must be screwed into the purlins or firing strips. If your metal panels are placed on decking, make sure your decking is adequate to secure the snow guards. Place your first staggered pattern of snow guards in, every other panel flat, along the Eave Strut (6 inches from the bottom edge on decking). Then move up to the first purlin above the eave strut (1 foot up from the bottom edge on decking) and place a snow guard in the center of each valley, alternating from the row below to create a staggered pattern that spans across the entire roof. Move up the roof every 5 feet and repeat the same staggered pattern of guards across the entire roof. Do not exceed 5 feet vertically between staggered patterns of snow guards. When possible, always attempt to divide the roof areas into equal sections, with equal distance between patterns of snow guards. It is highly recommended to screw into a purlin or structural support. This spacing recommendation can be slightly adjusted to accommodate locations of the structural support and purlins under the metal roof sheets. All upper roof areas must have a snow retention installed before installing snow guards on a lower roof. Never isolate areas of snow guards such as just over doorways or vent pipes.

Disclaimer

This page may be used only for the purpose of developing plans, specifications and/or approval drawings for construction projects utilizing only IceBlox, Inc. manufactured or distributed products and components. It is to be used only as a quick reference for estimating snow guard quantities and placement on roofs with less than 45 PSF ground snow load.

IceBlox Inc., d.b.a SnoBlox-Snojax, referred to hereafter as IceBlox, Inc., or any subsidiary brands or companies, is not responsible for estimates or purchases resulting from the erroneous or improper use of this page or snowguardspacingtool.com.

The user shall determine the suitability of the product for its intended use and assumes all risks of its use or handling. In regards to spacing guidelines, quotations and or layouts, Iceblox, Inc. will not be held liable for incorrect material quantities not recommended on snowguardspacingtool.com and/or SnoBlox-Snojax.com

SnowCatcher Spacing Frequently Asked Questions (FAQs)

The SnowCatcher snow guard comes with three holes pre-drilled in the base. We require using the two holes near the guard's face for installation. A third hole at the opposite end of the base is primarily for hanging the guard during the optional powder coating process. Still, it also acts as an additional mounting point for increased strength.

Regardless of the snow retention method used, isolated installations are never recommended. Before investing in snow guards, obtain a layout. One of the most important factors to consider when building a system for your project is the weight distribution of roof snow and ice across the whole structure. There is a considerable danger of failure with isolated installations, which could harm the roof's panels, structure, and snow guards. Damage from this could cost tens of thousands of dollars. It is advisable to speak with an architect or engineer before placing an order to ensure proper placement for snow retention.

Only polycarbonate snow guards should be mounted using adhesive. To get the strongest possible hold, Surebond SB-190 etches into the material. We never recommend installing metal pad-style snow guards with adhesive.

Color-matching for the stainless steel SnowCatcher snow guard is available in powder coating. Customers must send us a physical sample for analysis when they desire a bespoke color match. Once we find a match, we will provide a custom quote. Powder-coated orders have a typical lead time of 3-4 weeks for production. We do not keep color-matched guards in stock. Customers desiring a more economical or faster option can order the SnowCatcher in mill finish and either paint them or have them coated locally.

According to our tests, metal and polycarbonate snow guards exhibit comparable test results. Please refer to the resources page for our test results. For our consumers, the choice is frequently more dependent on aesthetics than strength. Roofers can only attach polycarbonate snow guards to standing seam roofs using adhesives.

Only projects in locations with a ground snow load of 45 psf or less should use our snow guard spacing charts. Please get in touch with the local zoning or building permit office if you are unsure of your snow load. Before placing an order, speaking with an architect or engineer is generally advisable. If your project is in an area with a snow load greater than 45 psf, please fill out the SnoBar Price Quote Form or the ColorBar Price Quote Form.