Spacing For Standing Seam Metal Roof Wind Uplift Resistance System

WindBar Standing Seam Metal Roof Noise and Wind Uplift Suppression

Spacing Guidelines

Coastal winds, microbursts, hurricanes, and tornadoes cause millions of dollars in metal roof damage every year. WindBar is a patented, external purlin system mounted with stainless steel, non-penetrating seam clamps, and our patented WindStopper foot. Once installed, a square bar spans between clamps, and the WindStopper is attached to the bar over the middle of the panel. The WindStopper foot holds down the middle of the panel, preventing lift caused by negative wind pressure. Engineered to increase a metal roof's wind uplift performance by up to 300%. This is the industry's only system that prevents seam disengagement while also preventing the pillowing of the panels. Metal roof damage can now easily be avoided with the use of the WindBar system. WindBar is designed to help your building meet the new tougher ASCE 7-98 wind code guidelines. WindBar can also be designed as part of a full snow retention system for additional protection from sliding snow and ice, all in one easy-to-install system. Isolating Windbar on partial roof sections such as just over doorways or roof vents in areas that receive snow and ice, is not recommended. This page should only be used only as a quick reference guide for estimating. Always consult with an architect or engineer for recommended snow guard placement for your project. This spacing guideline does not account for snow shadows, drifting, or unseasonable conditions.

All Roof Pitches

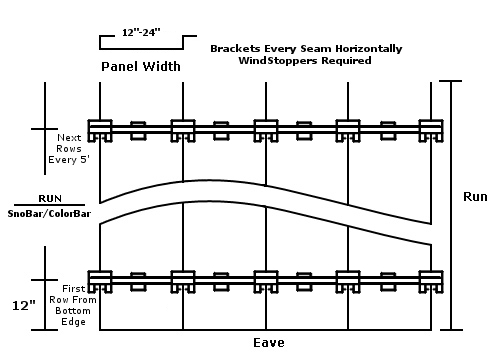

Panel: Valleys 12 to 24 inches.

WindStoppers Required: 12 inches to 17 inches needs 1 WindStopper Per Panel - 18 inches to 24 inches needs 2 WindStoppers Per Panel (Required)

Pitch: 10/12 to 12/12

Spacing: Every 5 feet up the roof.

Isolated Roof Areas: Never use WindBar in isolated roof areas such as just over doorways, etc. in areas that receive winter precipitation.

Snow load: Up to 45 PSF ground snow load.

Starting at 1 foot from the bottom edge, or over the end wall on a unsupported overhang, place the WindBar using one clamp per seam, across the entire roof area. Go up the roof every 5 feet and run another row of WindBar across the entire roof. Do not exceed 5 feet vertically between rows of bars. For Example: if your roof sheets are 10 feet long, your roof would require a row at approximately 1 foot from the bottom and at 5 feet up from the bottom. When possible, always attempt to divide the roof areas into equal sections, with equal distance between rows, without exceeding the manufacturer's maximum placement guidelines.

Disclaimer

This page may be used only for the purpose of developing plans, specifications, and/or approval drawings for construction projects utilizing only IceBlox, Inc. manufactured or distributed products and components. It is to be used only as a quick reference for estimating snow guard quantities and placement on roofs with less than 45 PSF ground snow load.

IceBlox Inc., d.b.a SnoBlox-Snojax, referred to hereafter as IceBlox, Inc., or any subsidiary brands or companies, is not responsible for estimates or purchases resulting from the erroneous or improper use of this page or snowguardspacingtool.com.

The user shall determine the suitability of the product for its intended use and assumes all risks of its use or handling. In regards to spacing guidelines, quotations, and or layouts, Iceblox, Inc. will not be held liable for incorrect material quantities not recommended on snowguardspacingtool.com and/or SnoBlox-Snojax.com

WindBar Spacing Frequently Asked Questions (FAQs)

Unlike our snow retaining rail systems, SnoBar and ColorBar, where the IceStoppers are optional, the WindStoppers are critical to the performance of a WindBar system and are a requirement. While the IceStoppers and Windstoppers are technically the same product, they serve very different functions between the systems. The Windstopper attachments fasten to the back of the bar mechanically and rest against the flats of the panel. While the feet of the Windstoppers are not mechanically attached to the panels, they apply pressure to the flats, forcing them tightly against the roof structure. This pressure prevents the panels from flexing and vibrating during high wind conditions.

In most cases, the WindBar system will feature more rows than even the most heavy duty snow retention layout. As such, it is capable of working both ways. One of our proudest examples of WindBar's dual purpose effectiveness is that it is trusted on several of the research stations in Antarctica. Antarctica has the highest sustained wind speeds of any continent, with gusts up to 200 mph.

Standard WindBar systems come with our 1" x 1" gator shield coated galvanized bars. The Aluminum 2" extruded bar is available, however, we find that this is typically unnecessary and overkill due to the heavy layout this system uses. The only situation where the aluminum bar should be used for WindBar is when the standing seam panels are greater than 24" wide and winter precipitation is common.

On standing seam panels with seam spacing of less than 18", one WindStopper per panel centered is required. Panels with seam spacing of 18"-24" require 2 WindStoppers per panel spaced evenly. Panels with seam spacing of larger than 24" require 3 WindStoppers per panel spaced evenly. WindStoppers are mechanically fastened to the back of the bar and rest against the panel. Do not mechanically mount the feet of the WindStoppers to the flats of the panel.

For WindBar systems, custom powder coating is offered at an additional cost. For accurate color matching, a physical color sample is usually required. Call us at 1-800-766-5291 for information on pricing and availability. Color-matched bar systems are not kept in stock and take 3 to 4 weeks for manufacturing. Customers can purchase a WindBar system in mill finish and spray paint it once it arrives or have it coated locally if they would rather take a speedier or more affordable route.