Enhancing Wind Uplift Performance: A Deep Dive Into the WindBar System

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Dec 11th 2023

Wind may be the biggest danger to your roof!

The dictionary defines wind as the natural or artificial movement of air at any velocity. Wind is often influenced by differences in temperature and pressure and can range from a gentle breeze to a powerful gust during a storm or hurricane. Wind is a major factor in determining weather and climate, carrying heat, moisture, pollutants, and pollen to new areas. Wind, while important and often pleasant, can also be dangerous and costly, especially when it comes to your roof. This is never more true than for our customers with standing seam metal roofs and those in areas with consistently high wind conditions. Luckily, we are armed with a solution for just these situations. We call it WindBar.

What is standing seam roofing?

Standing seam roofing is a stylish roofing solution with a typically long lifespan and extreme durability. Because of these factors, it is increasing in popularity but often can cost twice as much as an R-panel system. Standard r-panel roofing is installed directly to the roof structure with visible mechanical fasteners that securely hold the panel in place. Standing seam panels, on the other hand, have no visible fasteners or roof penetrations. The panels are normally snapped onto mechanically fastened clips that are hidden under the panels. This causes the panels to “float” above the roofing structure, allowing for thermal expansion. This gap, however, between the roof structure and the panels, can cause issues when wind is involved.

When standing seam clips are directly affixed to the framing, strong and gusty winds have the potential to generate sufficient pressure on the roof panels, leading to noise issues. The wind can induce a negative pressure, causing the standing seam roof panel to bow in the middle. Unlike R-panels or other through-fastened panels, these standing seam panels aren't directly fastened to the purlins or joists. Rapid bowing can occur due to gusty winds, causing the panel to hit the top of the purlin or bar joist with noticeable noise, often audible in the building. Depending on wind conditions, this can be an occasional singular knock or a consistent tapping or rattling in more extreme circumstances. In some high wind locations, dramatic noise from wind can make office buildings unusable due to volume. Beyond the noise concerns, panels may sustain damage if not adequately secured, with occasional instances of panels fracturing over time from repeated contact with the purlins. According to bankrate.com, 45.5% of home insurance claims reported in 2020 were related to wind damage. This figure dwarfed fire and lightning damage at only 23.8%. While insurance will often cover the cost of these repairs, it can increase the owner's rates.

What is WindBar?

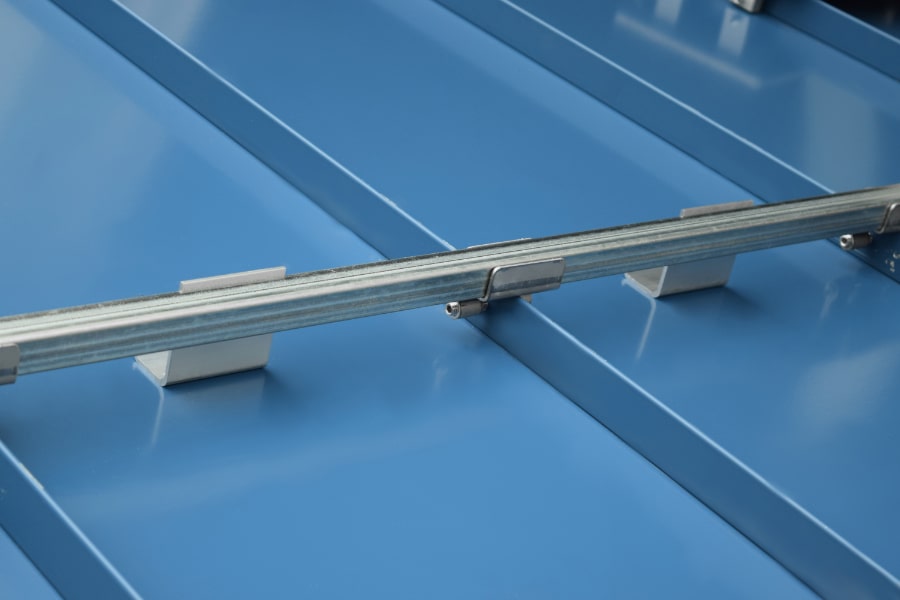

The WindBar system by SnoBlox-Snojax represents a groundbreaking approach to bolster the wind uplift resistance of standing seam metal roofs. This innovative, patented system incorporates horizontally installed galvanized steel or aluminum external purlins affixed with stainless steel, non-penetrating seam clamps, and the aluminum WindStopper. The WindStopper is attached to the rear of the bar, positioned between the panel seams at a perpendicular angle, and exerts downward pressure on the central flat section of the standing seam panel. This application of pressure restricts the panel's movement and significantly enhances the roof's ability to withstand uplift forces.

The WindBar system can be individually tailored using project-specific details supplied by the customer. This service is provided at no additional cost. WindBar is engineered to enhance the wind uplift performance of a metal roof by up to 300%. As such, the WindBar system stands out as the sole industry solution that not only successfully prevents seam disengagement but also delivers noise suppression advantages. As a bonus, because of the proximity of the multiple rows in a WindBar system, it also functions as a heavy-duty snow retention system.

Conclusion

The WindBar system is available in a galvanized finish or can be custom powder-coated directly from the manufacturer or by the customer, locally, upon arrival. The system is designed to be easy to install and offers a cost-effective solution for enhancing the wind uplift resistance of standing seam metal roofs. The WindBar system is a versatile and durable solution that is suitable for a wide range of roofing applications. For more information about the WindBar or to request a quote, you can fill out our online Bar Quote Request Form, email us at support@snojax.com, or give us a call at 1-800-766-5291. Don’t let the wind ruin your home or business!