Snow Guard Design 101: What Makes a Good Snow Guard?

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Dec 8th 2023

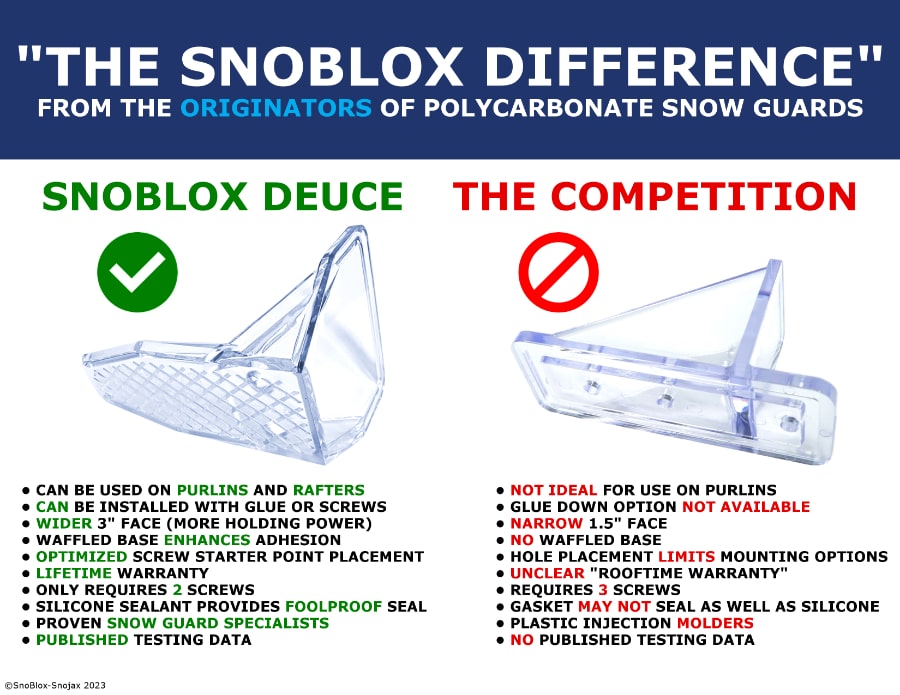

Not all snow guards are created equal!

Let’s be honest. The market is flooded right now with snow guards.

As patents from the long-standing major players in this industry

begin to expire, it seems like every Tom, Dick, and Harry are now

creating snow guards of their own. The majority of these models are

either slightly modified from stolen designs, or blatant knockoffs

that are often made from inferior materials in the pursuit of lower

prices and higher margins. Of course, there are also snow guards now

coming from companies that want a piece of the pie, but don’t have

the experience to back up their products or even understand effective

design strategies. Needless to say, some of the design choices made

by these companies leave us scratching our heads and have customers

wasting money and damaging their roofs. You may say to yourself,

“They all look the same to me. Does it really matter?” and my

response to you is an emphatic “YES!”. Let me explain.

Manufacturing materials make a huge difference!

The first part of designing any snow guard is selecting high-quality materials, made here in the USA. Foreign materials may not be held to the same standards and because of this, not all snow guards are created equal. A great example of this is when it comes to clear plastic pad-style snow guards. To the untrained eye, they may look the same, but there is more to it than color and visual appeal. Our clear snow guards, for example, are made from 100% virgin polycarbonate that is UV stabilized to help keep them from becoming brittle or turning amber in color over time. Some companies use the term “polycarbonate” generically in their advertising. The problem with this is that there are different grades of polycarbonate and sometimes they aren’t even using polycarbonate at all. It is not uncommon to find snow guards molded from acrylic which is less flexible, less resilient, more likely to become brittle, and not nearly as strong (30x less strong than polycarbonate to be exact).

Another example of material selection being important is when it comes to metal snow guards. Traditional metal snow guards have been commonly manufactured in cheap cast metal that has a tendency to oxidize quickly when exposed to weather. Cast metal may also be made from dissimilar metals that can leave rust marks, stain your roof panels, or become brittle. High-quality snow guards should be made from 304 stainless steel or aluminum that will not have an adverse reaction to your panels or become brittle in cold weather conditions.

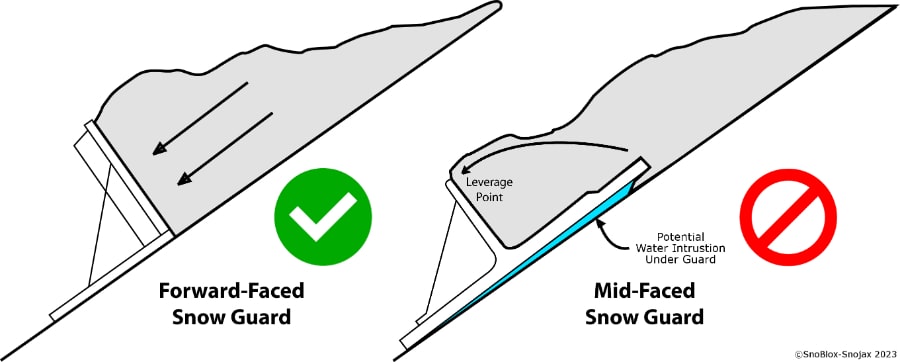

The snow guard's face is the barrier.

Next on the agenda

in the design process involves the face of the guard itself. This is

the part of the snow guard that will actually provide a physical

barrier against the snow and ice. It is important for the face to be

on the up-slope portion of the guard and supported by one or more

strong vertical struts to provide strength and structural stability

to the face. These struts will also keep the face from snapping off

or folding flat in more extreme conditions. Snow guards with their

faces in the mid-section of the base vs forward mounting can cause

headaches for their owners down the line. When pressure is put on the

center of the guard, it creates a cantilever effect and makes the

upper base pull away from the panel. This can rip

screws placed above

the face of the guard away from the roof, causing damage to the

panels and structure underneath. This can lead to roof leaks. As

moisture travels under this gap and refreezes, it can expand

compounding this problem. In worst-case scenarios, it can even snap

the guard in half. When designing

snow guards that are meant to be

installed with mechanical fasteners, screw hole placement is of vital

importance. An effective design will place 2 screws horizontally side

by side and directly below the face of the guard, which will be

oriented up the slope. This proven design method puts the mechanical

attachments right at the face and eliminates the possibility for

moisture to travel under the top of the guard.

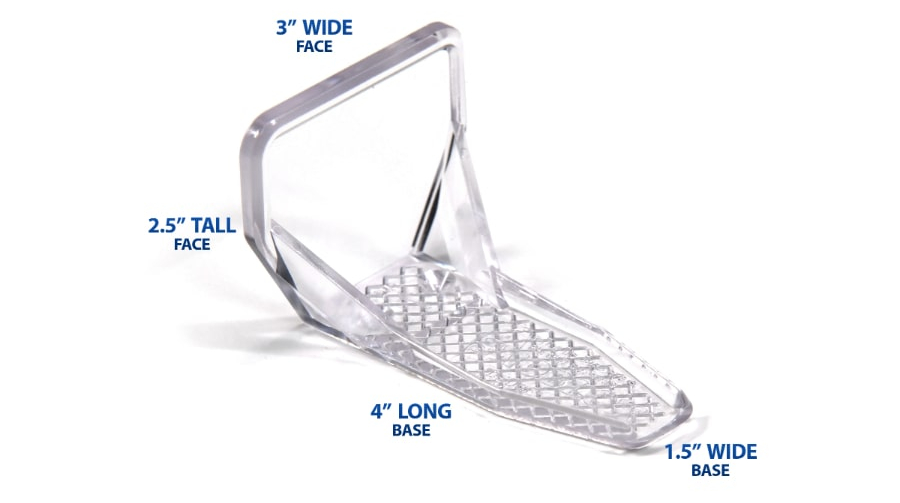

Impacts of different bases on attachment

Circling back to

plastic

snow guards, another design element that has a major impact

on performance is the base itself. When you install plastic guards

with adhesive, like

Surebond SB-190, you will often find snow guards

with smooth bases. When they are installed according to the

manufacturer’s recommendations and with a proper

layout,

smooth-based guards can be very effective. However, if you are

looking to really beef up your system, then you should be looking for

a model with a waffled base, like our SnoBlox Ace or Deuce models. We

have found that snow guards with waffled bases offer nearly three

times the strength of smooth bottom guards of the same size. A

waffled base provides a stronger holding texture and more surface

area for the adhesive to bind to.

In conclusion, make sure that you do your homework before making your purchase. Everyone loves a bargain, but at the end of the day, saving a little bit of money initially at the time of purchase may cost you significantly more in future repairs or replacement costs due to poor quality and/or design. For more information about any of our snow retention products, you can send us an email to support@snojax.com or give us a call at 1-800-766-5291