Metal Roof Snow Guards Spacing

Snow Guard Spacing Hub for Metal Roofs

Choose your roof type to open spacing charts, calculators, and installation guidelines.

Need spacing guidance fast? This hub links directly to spacing charts, calculators, and installation notes for all SnoBlox-Snojax snow guard systems.

Why Proper Snow Guard Spacing Matters

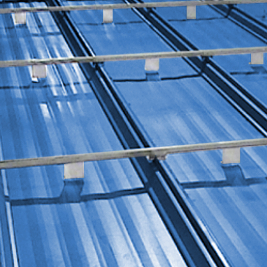

Glossy-coated metal roofs can release snow and ice suddenly, creating dangerous slides that damage gutters, walkways, vehicles, and landscaping. Proper snow guard spacing distributes the load across the entire roof surface, so snow melts gradually rather than dropping in large sheets.

A single row of guards is usually insufficient. Most roofs require multiple staggered rows across the roof width, depending on roof pitch, panel type, and ground snow load. The pages linked below provide system-specific spacing charts, diagrams, and installation notes.

Standard SnoBlox-Snojax spacing recommendations apply to projects up to a 45 PSF ground snow load. Heavier loads require a manufacturer-recommended SnoBar® or ColorBar layout.

How to Use This Hub

- Identify your roof type.

- Select the appropriate spacing guide below for charts, diagrams, and installation notes.

- Use calculators or quote forms to confirm exact quantities where available.

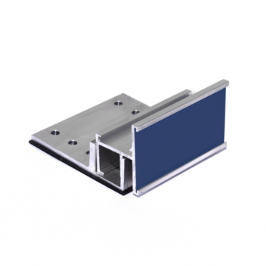

Standing Seam Snow Guard Spacing Guides (Rails, Cleats & Adhesive Systems)

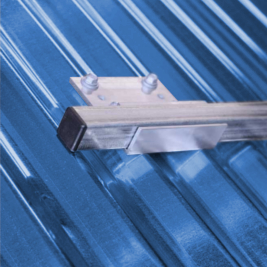

Screw-Down Metal Roof Snow Guard Spacing Guides (PBR, R-Panel & Corrugated)

Other Roof Types & Specialty Wind Guard Systems

Snow Guard Spacing FAQs

Do I need multiple rows of snow guards on my metal roof?

In some cases, a single row will be adequate, especially if the roof runs are short. On longer slopes, a single row at the eave rarely stops a full sheet of sliding snow. Multiple staggered rows distribute weight evenly across the roof surface and greatly reduce the force placed on the lowest row. Each spacing chart linked above shows the row count recommended for that system.

Does roof pitch change how far apart the snow guards get spaced?

Roof pitch influences both row spacing and the recommended number of snow retention rows. Steeper roofs shed snow faster and typically require additional rows, evenly spaced up the roof to prevent snow and ice from moving. Each spacing guide includes pitch-specific recommendations based on how that system performs under load.

Can I isolate snow retention systems above doors?

No. Isolated rows concentrate all the sliding force in one small area and often fail. Snow guards must be installed across the entire roof width to distribute the load evenly. We never recommend localized placement for most SnoBlox-Snojax snow guards. The only exception to this rule would be if you used the snowBreaker and spaced the snow guards in a V pattern, as shown on the SnowBreaker Isolated Spacing Chart.

Are screw-down guards OK on standing seam?

No. You must never puncture a Standing seam metal roof. Doing so may damage the panel and void warranties. Use adhesive-mounted guards, seam-mounted SnoCleat RC/RCT, or clamp-on SnoBar® and ColorBar rails instead. Each spacing page above lists the correct attachment method.

How do I know which snow guard system works best for my metal panel?

System selection depends on roof type: standing seam, exposed-fastener, PBR/R-panel, or 2.67 corrugated. Each image block above links to a dedicated spacing page that explains which snow guards are compatible with your profile and how to space them.

What if my project has a ground snow load above 45 PSF?

Projects with heavier snow loads require manufacturer layouts to ensure proper load distribution. Contact SnoBlox-Snojax for a custom SnoBar® or ColorBar layout before ordering materials.

Do adhesive-mounted snow guards require a specific amount of cure time?

Yes. Adhesive systems such as SB-190 must cure fully before the roof if subject receiving a snow load. Cure time varies by temperature and humidity. The adhesive spacing and installation guide linked above provides detailed preparation and cure information.

If you space the rows of snow guards too far apart, will you weaken the system's ability to hold snow and ice?

If you space rows of snow guards too far apart, the system can't retain snow and ice as it should. Push it past the limits, and guards can bend or even pop off under the weight. Ensure proper spacing, as indicated in our charts, to evenly distribute the snow load across the roof.

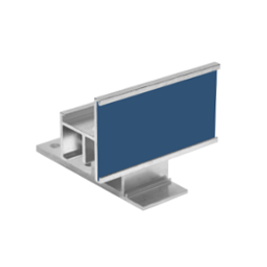

Glue-Down Guard Spacing

Glue-Down Guard Spacing SnoBar® Rail Spacing

SnoBar® Rail Spacing ColorBar Rail Spacing

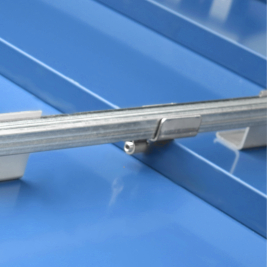

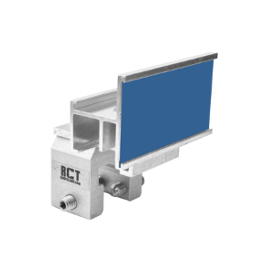

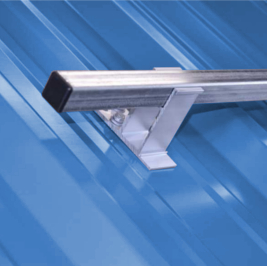

ColorBar Rail Spacing SnoCleat RC / RCT

SnoCleat RC / RCT Poly Screw-Down Spacing

Poly Screw-Down Spacing SnowCatcher Spacing

SnowCatcher Spacing SnowBreaker Spacing

SnowBreaker Spacing Screw-On SnoBar / ColorBar

Screw-On SnoBar / ColorBar SnoCleat PBR Spacing

SnoCleat PBR Spacing 2.67 Bar Rail Spacing

2.67 Bar Rail Spacing SnoCleat 2.67 Placement

SnoCleat 2.67 Placement Shingle Roof Guard Placement

Shingle Roof Guard Placement WindBar Spacing

WindBar Spacing