Buyer Beware: The Truth About Set Screws

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Nov 30th 2023

Getting to the truth of the matter.

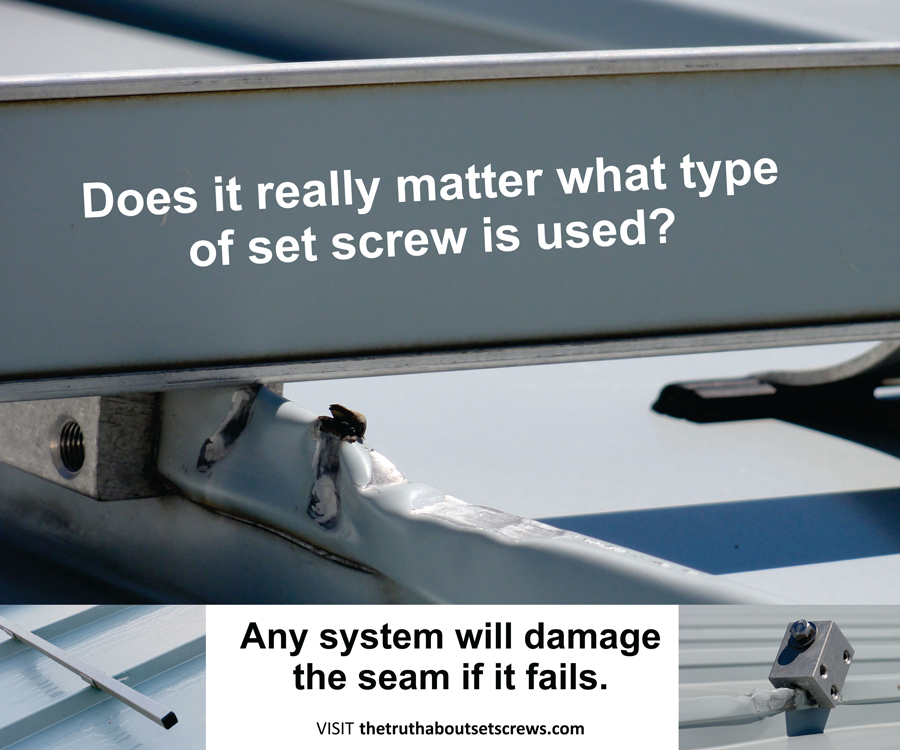

Numerous rumors and misconceptions circulate about roof clamp set screws and their attachment to standing seam metal roofs. Competitors consistently assert that cupped tip set screws cause scratches and galling on panel seams, leading to warranty voiding and premature corrosion. They promote their own supposedly superior "patented" round tip set screws as a solution, claiming they prevent scratches and protect the paint finish.

Comprehensive testing

In response to this marketing hype, we have undertaken a comprehensive test, installing both cupped tip and round tip set screws on identical test panels to assess the validity of these claims. Our evaluation aims to address the following questions:

- Do cupped tip set screws expose bare metal, leading to premature corrosion?

- Do round tip set screws scratch the paint or expose bare metal?

- How does the proper installation of either clamp impact seam integrity?

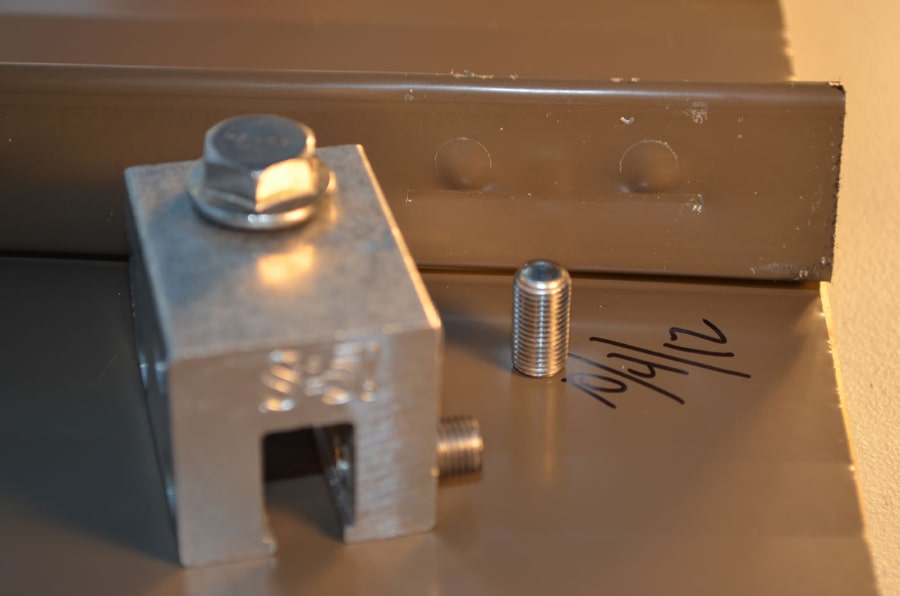

Both round tip and cupped tip set screws have been utilized in metal roof clamps since the early 1990s. Clamps employing these screws attach to seams differently, with cupped tip screws creating a positive anchor point through proper torquing to 90 in./lbs. Round tip set screws, on the other hand, rely on high torque and panel compression for stability, requiring torques ranging from 130-180 in./lbs. It is important to note that a significant difference between these two types of screws is that most round tip set screws have fine threads which can cross thread with the required high torque settings. This is especially true when used in aluminum clamps which are softer than stainless steel. This can often make these screws and clamps non-serviceable after initial installation. Cupped tip set screws require less torquing. Because of this, their coarse threads prevent them from binding, even when used in aluminum clamps. The following video demonstration showcases the results of using high-compression round point set screws versus cupped point set screws.

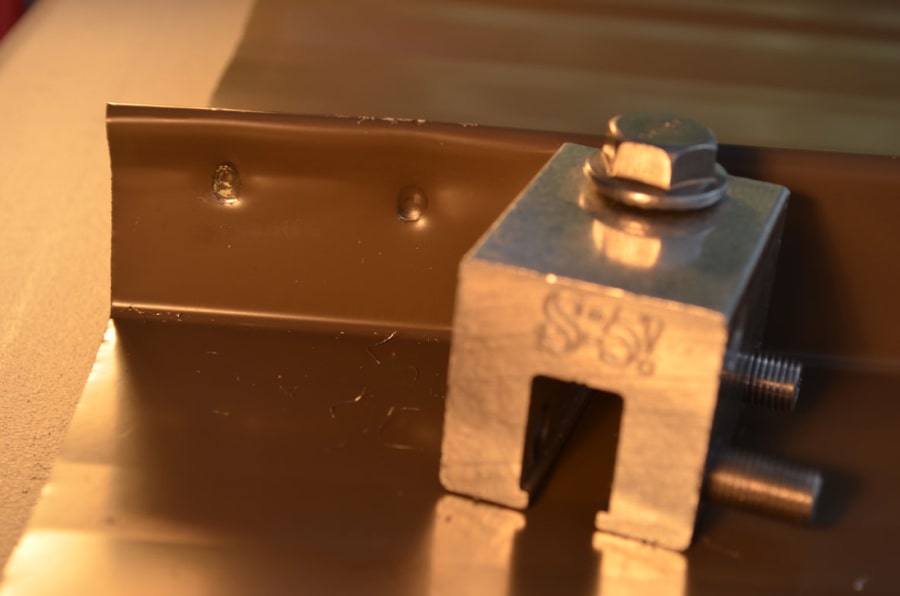

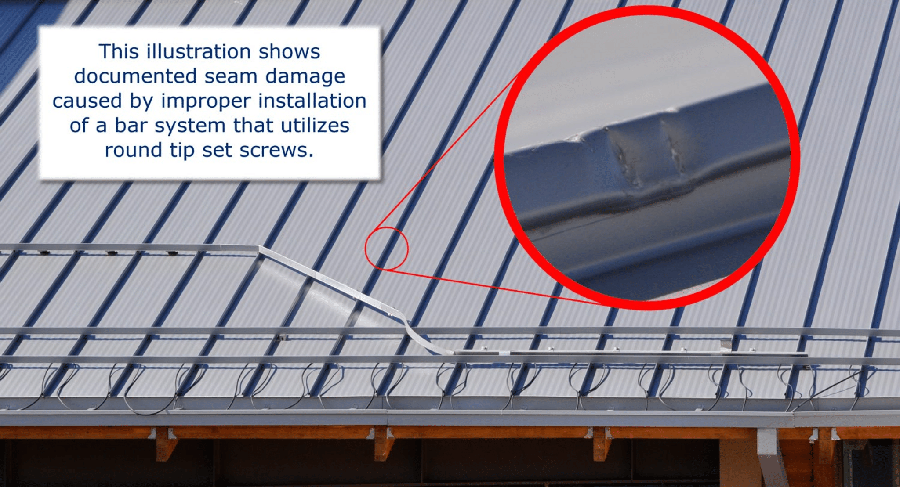

The competition's clamp

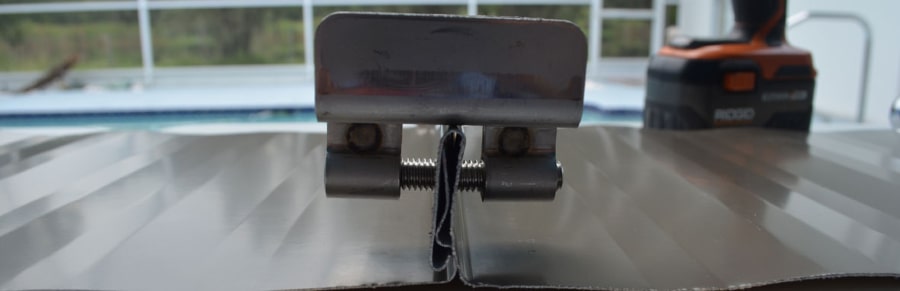

Our demonstration features a Competitors Brand U-Clamp and Competitors Brand S-Clamp, using round tip set screws on 24ga. Snap Lock test panels. Despite claims by a competitor regarding the harmful effects of other set screws, our installation adhered to manufacturer instructions and torquing recommendations. The video will meticulously document the installation process, seam distortion, and "panel dimpling" on both sides of the panel. Contrary to competitors' assertions, we observed that clamps with round tip set screws could take significantly longer to install than those with cupped tip set screws.

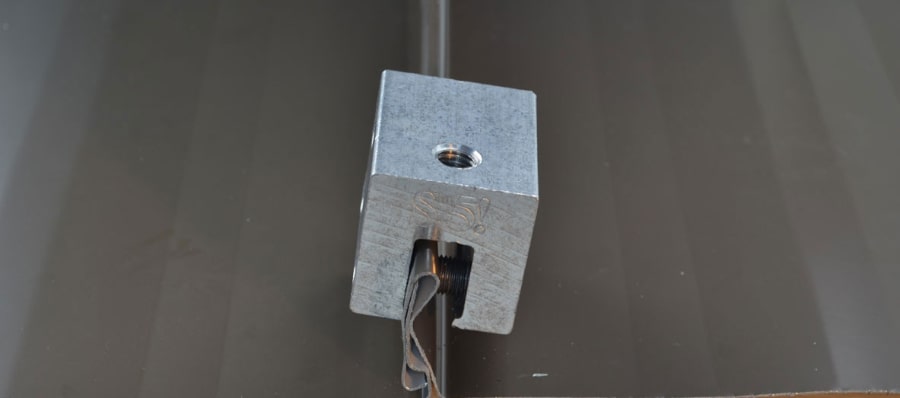

Our SnoBar Clamp

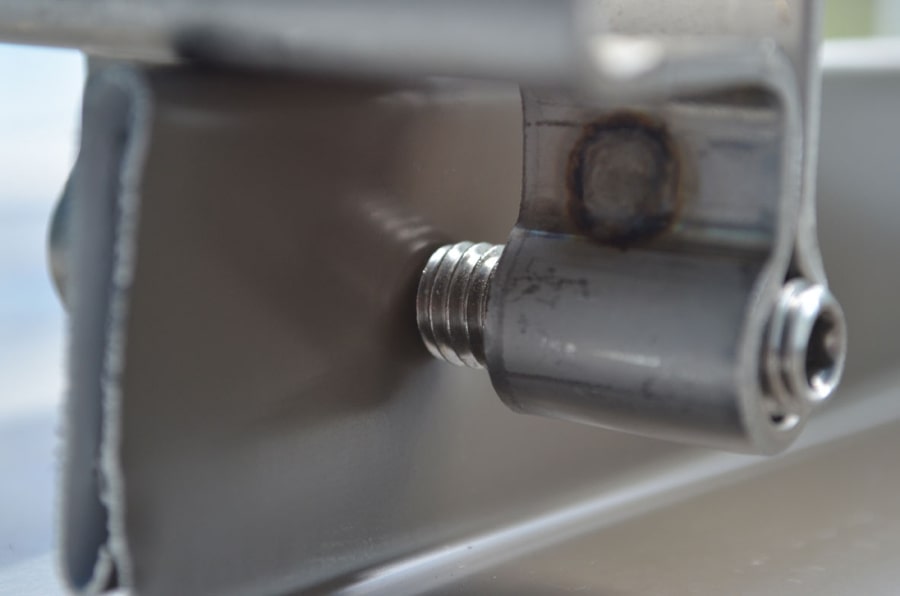

The SnoBar clamp, equipped with cupped tip set screws, was also subjected to the same testing conditions. This clamp, in use since the early 1990s, demonstrated minimal seam distortion and no extraneous scratches or breaches on the painted surface around the screws when properly torqued to 90 in./lbs. While cupped tip set screws may penetrate the painted finish to ensure a positive lock, the sealed area between the tip of the set screw and the seam eliminates exposure to the elements. Images from the experiment clearly depict an undamaged seam profile and side views show no exposed bare metal when the SnoBar clamp is appropriately torqued. The findings challenge the competitor's claim that their round tip set screws are the only solution for preserving delicate panel finishes and warranties.

Unfounded allegations

These unfounded allegations suggest that roof panels are so fragile that any scratches would void the warranty and accelerate premature corrosion. The reality is that every metal panel exposes bare metal along the edges, cut ends, and sometimes around screw holes. If standard installation practices were truly catalysts for corrosion, one would expect widespread corrosion on most if not all metal roofs in the field. This, however, is not the case, rendering such assertions baseless. To our knowledge, no warranty has ever been invalidated due to properly used cupped tip set screws on a metal roof, nor have we observed premature corrosion in the attachment areas of properly installed clamps with cupped tip set screws.

Our tests indicate substantial disparities between the claims of competitors and our actual findings. When round tip set screws are appropriately torqued (between 130-150in./lbs.), the contact point can breach the delicate paint finish, and the clamp body can scratch the paint down to the bare metal.

It is worth noting that when round tip set screws are properly torqued, they not only dimple the set screw side of the seam but also stretch the metal on the opposite side. This stretching can result in breached paint rings around the affected metal areas.

Given that these clamps are intended for permanent installation, some of the paint damage is shielded by the set screws and clamp body. However, certain breached paint areas on the opposite side of the panel may potentially be exposed to the elements.

Summary

In summary, our tests were conducted in response to misleading marketing claims by competitors. Contrary to these claims, our findings indicate that properly installed SnoBar clamps with cupped tip set screws are less likely to expose bare metal to premature corrosion than their counterparts with round tip set screws. Furthermore, our tests demonstrated that higher torque set screws (round tip) can cause significantly more seam distortion compared to the 90in./lbs. torque required for cupped tip set screws.

To conclude, it is acknowledged that any set screw, when properly installed on metal roof panels, can breach the paint. There are no miraculous set screws that shield the paint finish, but some set screws inflict less damage than others. Regrettably, misleading claims regarding cupped tip set screws have persisted for years, causing unwarranted harm to their reputation. Nevertheless, the truth prevails. After reviewing our video demonstration, we invite you to assess whether the claims against cupped tipped set screws hold true or false and encourage you to share the video with design professionals in your industry.

For a more thorough look at our investigation, we encourage you to visit truthaboutsetscrews.com. You can also give us a call at 1-800-766-5291 or email us at support@snojax.com.