Snow Guards: What Works What Does Not

Do Snow Guards Really Work on Metal Roofs?

Snow guards are effective on metal roofs, but only when they are correctly spaced and installed across the entire roof. Most failures occur because installers use too few guards, place them only at the eave, or use them on a roof panel that is not compatible with the snow retention system. This page explains which snow guard approaches work, which ones fail, and why proper layout and load distribution matter more than the snow guard type itself.

What Works vs. What Fails With Snow Guards

| What Works | What Fails |

|---|---|

| Staggered rows across the roof | Rows placed in a straight line |

| Proper snow guard spacing based on roof length and pitch | Guessing quantity or spacing |

| Properly designed & tested snow guards | Untested Snow guard designs |

| Full roof snow load distribution | Concentrated guards in one area |

Common Causes of Snow Guard Failure

| Failure Cause | Why It Fails |

|---|---|

| Too few snow guards | Snow load exceeds holding capacity |

| No snow guards on upper roofs | Upper roof snows slide off onto bottom roof |

| Incorrect spacing | Uneven load transfer causes pull-off |

| Ignoring roof pitch and snow load | Forces exceed design limits |

Snow Guard Layout Performance Comparison

| Layout Type | Performance | Why |

|---|---|---|

| Full-coverage staggered rows | Consistently performs best | Evenly distributes snow loads |

| Multiple straight rows | Sometimes acceptable | Better than one row, less efficient |

| Single inline eave row | Fails most of the time | Subjects snow guards to impact |

Snow Guard Myths vs. Facts

| Myth | Fact |

|---|---|

| One row of snow guards is adequate on a steep roof | Steep roofs usually require multiple rows to properly distribute snow loads |

| Snow guards stop all snow from sliding | Snow guards mitigate snow movement; they do not stop melting or shedding of small pieces |

| Bigger or stronger snow guards mean fewer are needed | Proper quantity and spacing matter more than individual snow guard size |

| Isolated snow guards will protect a doorway or vent pipe | Unbalanced snow loading on the snow retention system may cause attachment failure |

| Snow guard failures are caused by poor designs | Most failures result from improper layout, spacing, or installation methods |

Why Snow Guards Fail on Metal Roofs

Snow guards can fail on metal roofs for various reasons, including poor design, incorrect installation, or mismatched systems. Common causes of snow guard failure include installing too few snow guards, placing them only at the eave, neglecting the importance of roof pitch, and exceeding the rated capacity of the snow retention system. By understanding the most common reasons snow guards fail on metal roofing, property owners and contractors can select the appropriate snow retention system on the panels used for the project, proper spacing patterns, and the right attachment method for optimal long-term performance.

What Makes Snow Guards Actually Work

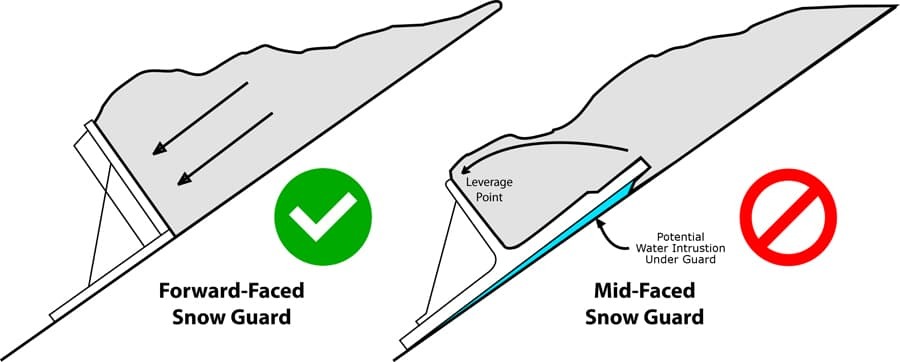

It is best to identify your metal roof type before choosing a snow retention system. Attachment methods vary by roof style and can affect performance and roof warranties. Exposed-fastener (screw-down) metal roofs can support mechanically fastened snow guards or snow rails, but some property owners prefer to avoid drilling new holes. In those cases, adhesive-mounted polycarbonate snow guards are a practical alternative. Standing seam metal roofs should never use screw-mounted snow retention because screw penetrations may restrict panel movement and void the roof warranty. The most common snow retention options for metal roofs include screw-down snow guards and rails for exposed-fastener panels, seam-mounted clamp-on snow guards and rails for standing seam systems, and adhesive-mounted polycarbonate snow guards for a non-penetrating installation.

Snow Guards: What Works and What Doesn't (FAQs)

Snow guards work when they are properly selected, correctly spaced, and installed properly across the entire roof. Systems that distribute snow loads evenly across the whole roof surface consistently perform better than isolated or single-row installations.

Screw-down snow guards should only be installed on exposed-fastener metal roofing. Never screw snow guards into a standing seam panel. Follow the recommended installation methods to secure mechanically fastened snow retention systems properly.

Proper spacing allows snow loads to be distributed evenly across the entire roof, not just over doorways and ventpipes. Spacing snow guards too far apart and isolating them can overload the guards and increase the risk of failure.

Snow guard failures often occur due to improper installation techniques. Problems with a project usually arise when clustering guards above doorways and vent pipes, when ignoring spacing guidelines, and when exceeding the roof snow-load limits of the snow retention device.

Most snow guard failures result from misinstallation and ignoring layout recommendations, rather than from defects in the guards themselves. The most common failures result from improper spacing, inadequate placement, and not taking the roof pitch and snow load into consideration.