Adhesive Snow Guards Info

Adhesive-mounted snow guards are installed using a strong adhesive that bonds the snow guard to the roofing material. SnoBlox-Snojax pioneered the use of SureBond SB-190 to attach plastic snow guards. This adhesive creates a secure attachment, up to 2000 pounds tensile strength, without the need for drilling or screwing into the roof.

Polycarbonate snow guards can usually be bonded on just about any factory painted metal roofing panel that is in good sound condition. It will only be as good as the surface to which it is attached. To ensure compatibility and proper installation, it's often best to consult with an experienced roofing professional or reputable snow guard manufacturer. They can provide spacing guidence guidance based on your specific roofing system, location, and needs.

The roof surface where the snow guards will be installed must be dry and cleaned with high quality alcohol wipes to ensure proper adhesion. We only recommend using SureBond SB-190 liquid adhesive. The outside temperature must be above 50 degrees Fahrenheit for at least 28 days. If the temperature dips below 50 degrees, the cure time will be extended. The application becomes waterproof about 45 minutes after installation.

Refer to the adhesive mounted snow guard placement guideline. Proper installation and spacing is crucial for adhesive-mounted snow guards to work effectively. The surface must be clean, dry, and free from debris before applying the adhesive. SB-190 adhesive is applied to the snow guards are then they are firmly pressed onto the roof with a squeeze out around the perimeter. The outside conditions should be optimal for the proper curing to take place according to the adhesive manufacturer's instructions.

The spacing and placement of adhesive-mounted snow guards are determined based on factors such as roof pitch, snow load, and local climate conditions. Properly spaced snow guards help distribute the snow load evenly across the entire roof. It is important to follow the manufacturers' spacing guidelines for a successful installation.

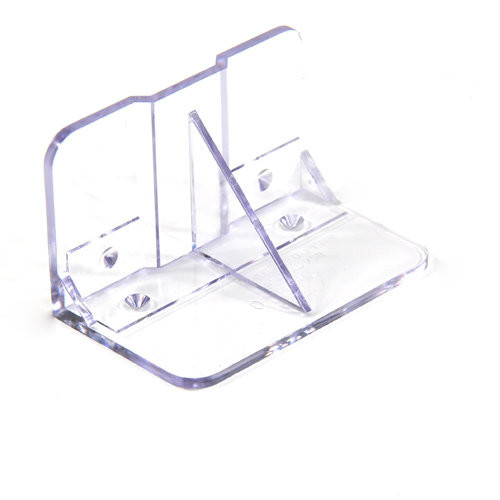

Adhesive-mounted snow guards should only be made from UV stabilized virgin-grade polycarbonate. They can come in many different shapes, sizes, and colors. The choice of shape, size and color depends on factors such as aesthetics, durability, type and shape of the metal roof panel used on a specific roofing project.

Adhesive-mounted snow guards generally require minimal or no maintenance. Recurring inspections should be conducted to ensure they remain securely attached and free from debris. If an adhesive mounted snow guard dislodges, simply clean and reapply in the same glue spot.

Some benefits of adhesive-mounted snow guards include their ease of installation and potential long-term sustainability that can match the metal roof. They do not require roof penetration, which helps maintain the roof's integrity by avoiding potential leaks associated with screw holes in a steel roof.

Adhesive Mounted Snow Guards Frequently Asked Questions (FAQs)

We base snow guard layouts on the ground snow load for a specific town, city, or county. Meteorologists calculate a snow load by averaging multiple years of winter precipitation data. Even the best layout can fail if a specific geographic location receives unusually high snow and ice levels. The glue-down system's beauty lies in its ability to release the guards from the roof without damaging the guards, roof panels, or structure if unfavorable weather conditions arise. Once the weather warms up, you can re-attach the guards.

We produce our clear snow guards in the USA from 100% virgin polycarbonate. Polycarbonate is strong, lightweight, and thirty times more durable than acrylic. Its UV stabilization keeps it from deteriorating and making the guards fragile. It is the same material used on astronauts' face masks.

Depending on your skill level, installing adhesive-mounted, pad-style snow guards can be quick and easy. Many of our clients are do-it-yourself homeowners. Installation guidelines are available on our website and sent with your order. The riskiest part of installing snow guards is working safely on a slippery, sloped metal roof. Please ensure you utilize appropriate fall protection, such as the RidgePro, before starting an installation and climbing onto your roof. Any licensed general or roofing contractor should be capable of installing these guards for you if you choose to hire a professional.

Not all plastic snow guards are created equal. We only utilize virgin, UV-stabilized polycarbonate made in the USA. Our polycarbonate snow guards may lose some clarity with time, but they rarely amber.

Correctly installed snow guards with a properly designed layout should require little to no maintenance. We recommend a yearly inspection, typically in the spring, to determine if any have become dislodged from the roof. In the event of a release, you can clean the roof with soap and water, then re-apply the guard to the same spot with SureBond SB-190. The newly applied SureBond will bond to the existing adhesive on the roof.

The purpose of a properly designed layout is to distribute the weight of the snow and ice over the entire roof surface without isolating it into a small section.

The only adhesive we recommend our customers use for installing our clear, polycarbonate snow guards is SureBond SB-190. This glue is the industry standard and our only choice after years of comparison testing against many other adhesives.