Navigating Snow Guard Attachment: Screw Down Metal Roofs vs. Standing Seam Metal Roofs

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Dec 14th 2023

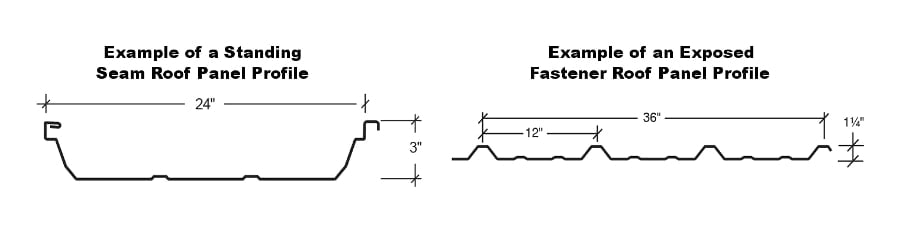

In regions where snowfall is a common occurrence, the importance of snow guards in protecting metal roofs cannot be overstated. These devices play a crucial role in preventing sudden and potentially dangerous snow slides. When it comes to attaching snow guards, two popular metal roofing types stand out: screw-down metal panels, like the R-Panel or PBR, and standing seam metal panels like the Snap-Lok and Double-Lok. In this blog, we will explore the key differences in attaching snow guards to these distinct roofing systems.

Screw Down Metal Roofing

Screw-down metal roofs, also known as exposed fastener metal roofs, are characterized by the presence of visible screws that secure the panels directly to the roof structure. When attaching snow guards to any roof, one must consider the placement of these guards. Snow guards are typically installed above the screw lines to prevent interference with the roof's weatherproofing capabilities. It is also important to make sure you are getting a proper layout with rows traveling the full length of the roof and often with multiple rows going up the slope. This prevents overloading and allows for equal weight distribution over the entire roof surface. Isolated placement in areas just above doorways, walkways, chimneys, and HVAC units is never recommended. You can check out our Spacing Guidelines Page for more information about proper layouts with the different attachment methods.

Screw Down Metal Roofing Snow Guard Advantages

The advantage of attaching snow guards to screw down metal roofs is the simplicity of the process. These roofs offer much more flexibility than their standing seam counterparts when it comes to the types of snow retention that can be installed and the methods used to do it. Pad-style polycarbonate snow guards, like the SnoBlox Deuce and Icejax II, can be glued down with Surebond SB-190 adhesive or screwed down with mechanical fasteners and NovaFlex MR150 liquid sealant. When choosing between these methods of attachment, it is important to remember that Surebond SB-190 requires approximately 28 days at 50 degrees Fahrenheit or above to achieve a full cure and that no less than 1” of material is recommended when attaching to wood structures with screws. Metal pad-style guards like the SnowCatcher or SnoCleat PBR can also be screwed into the panels, but use a foam gasket for sealing instead of liquid silicone. For high snow load areas or locations with extreme weather conditions, a screw-down bar system, like the SnoBar or ColorBar Snow Rail Systems, can also be utilized. Rail systems are installed in straight-line configurations as opposed to pad-style guards which require staggered installation for improved load distribution.

Standing Seam Metal Roofing

Standing seam metal roofs offer a sleek and modern appearance with concealed fasteners beneath the overlapping seams. The panels “float” above the roof structure allowing for expansion and contraction. When attaching snow guards to standing seam roofs, the options become a little more limited due to their design. Screw-down pad-style snow guards and rail systems are never recommended for this type of roofing. Penetration of the panels can lead to panel deformation, roof leaks, and/or loss of the manufacturer’s warranty. For these kinds of roofs, we recommend either using the Surebond SB-190 adhesive with polycarbonate pad-style guards or installing a rail system with non-penetrating clamps. The metal clamps attach with cup-tipped set screws to form a permanent attachment once they are torqued to the seams.

Considerations for Both Roof Types:

Roof Pitch:

The pitch of the roof plays a vital role in determining the type of snow guards needed. Steeper pitches often require more aggressive snow guard layouts and/or more heavy-duty snow retention systems to effectively hold back accumulating snow and ice.

Snow Load:

The geographical location and the expected snow load are critical factors. Areas experiencing heavy snowfall may require more robust and strategically placed snow guards. We never recommend the use of individual pad-style snow guards in areas where ground snow load exceeds 45psf. This is true for glue-down or mechanical fastening options.

Material Compatibility:

Whether the roof is made of steel, aluminum, or another metal alloy, it's essential to choose snow guards made from compatible materials to prevent corrosion or other issues. Certain adhesives and sealants contained acetic acid my not be compatible with copper or galvalume roofing and should not be used in these instances. Additionally, the use of bare aluminum snow guards and rail systems should be avoided with copper roofing as well. Having your metal snow guards or rail system powder coated, either directly from the manufacturer or locally, will create a color-matched protective shell around your snow guards which should help prevent any negative reactions while also adding to your roof’s style.

In conclusion, the differences between attaching snow guards to screw-down metal roofs and standing seam metal roofs lie in the roofing system's design and the methods employed to maintain a secure attachment. Regardless of the roof type, careful consideration of factors such as roof pitch, snow load, and material compatibility is essential to ensure the effective and lasting performance of snow guards in protecting against potentially hazardous snow slides. For more information about our snow guards or to place an order, you can send us an email at support@snojax.com or give us a call at 1-800-766-5291.