ColorBar Snow Bars Enhance Safety for Your Metal Roof

ColorBar snow rails are essential for preventing rooftop avalanches that wreak havoc on your property. Snow bars effectively manage snow accumulation and protect your gutters, HVAC units, vehicles, and landscaping from costly damage. Additionally, they enhance safety by reducing the risk of injuries caused by falling snow. Investing in ColorBar snow rails will help safeguard your property and prevent liability from falling snow and ice.

Extruded Aluminum ColorBar, Roof Clamps, and Mounting Bracket

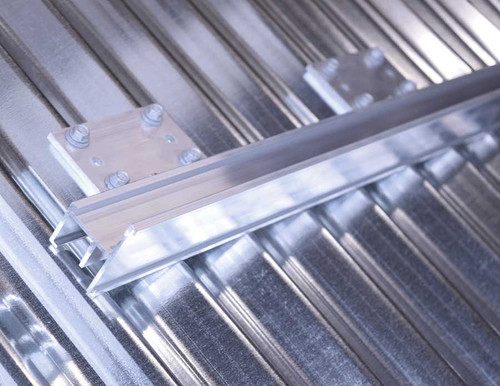

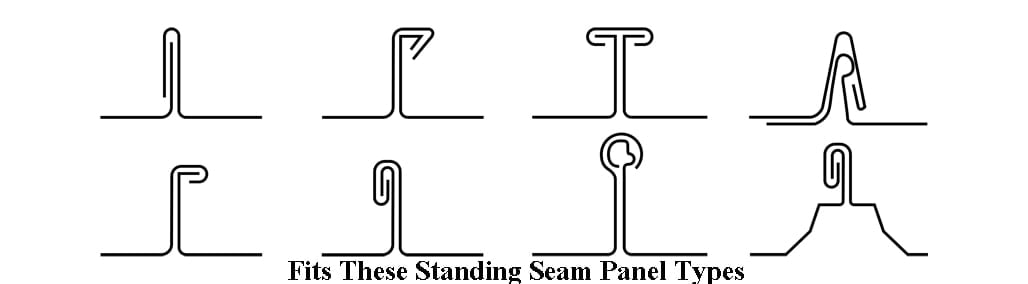

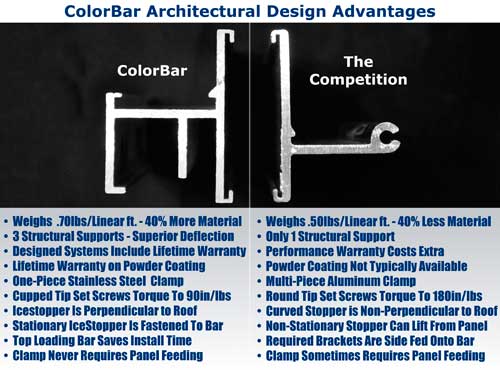

The face of the 6063 T-5 aluminum ColorBar snow rail features top and bottom channels that can accept optional 2" metal color strips, usually available from the project roofing supplier. The RCB-3 (Roof Clamp Bracket) mounts the ColorBar to the patented universal-fit RoofClamp RCT. It fits many more standing seam roof panel profiles (see clamp comparison) than our standard stainless steel SnoBar® clamp.

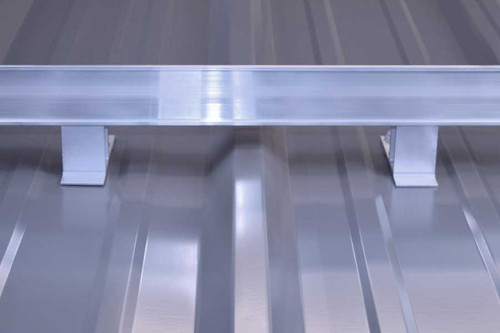

The ColorBar Mounting Bracket and Snow Rail Roof Clamping System

The aluminum RCT RoofClamp that fastens the snow bar to the panel seam uses three low-torque stainless steel cup-tipped set screws. The 90-inch pounds of torque required to attach the cup-tipped set screws to the metal roofing panel is considerably less than slippery round or oval point set screws. The RCB-3 ColorBar features top-loading bar brackets that install quickly and can swivel up to 31 degrees for mounting the snow retention system in converging hips or valleys.

RCB-3 ColorBar Snow Rails are Safe for Standing Seam Metal Roofs

Because it clamps to the panel seams of the roof, the standing seam ColorBar ensures no risk of damaging roof seams with screws or holes. The difference between the galvanized square tube SnoBar and the aluminum ColorBar is that the ColorBar is a rail-style snow retention system designed to connect with included splice connectors to allow the bar to run continuously over the length of the roof. This product is perfect for standing seam metal roofs with its one-piece aluminum clamp featuring three non-penetrating cup-tipped set screws. The roof clamps do not require panel feeding, and the ColorBar drops into the aluminum RCB-3 mounting bracket.

The Shape of The Snow Bar Matters

The ColorBar snow rail, paired with the optional streamline IceStoppers, features a flat bar with a face that holds snow and ice from the top of the bar down to the panel flat. All snow retention systems must mitigate the movement of snow and ice on the flat portion of the panel where the snow and ice slides occur. A single round pipe-style snow fence may allow snow and ice to ramp up, over, and/or slide under the snow bars. Multiple round pipe-style snow fence systems often require unsightly flat pieces of stock metal on the face of the bars to prevent snow and ice from sliding under and through the bars.

IceStoppers Prevent Snow and Ice Slides Under The Bar

Imagine parking next to a building and suddenly having snow and ice fall from the sloped metal roof above. This unpleasant surprise can happen with snow rails that do not have IceStoppers installed. For safety reasons, using IceStoppers in pedestrian and parking areas is strongly advised.

RCB-3 ColorBar Strength and Durability

The heavy-duty ColorBar's three support brackets are structural in nature. The unmatched strength of the ColorBar snow rail allows this snow retention system to span metal panel seams up to 42 inches. We would not suggest doing that with a single snow bar with only one support brace. The aluminum ColorBar rails, mounting brackets, and roof clamps will not rust or corrode on your metal roof; we guarantee it for life!

RCB-3 ColorBar Key Features:

-

Continuous Aluminum Snow Rails With Splice Connectors

-

Also Fits Bulb-Seam and T-Seam Panels

-

Swivels up to 31 Degrees in Converging Hips and Valleys

-

Year Round Installation

-

Easy Installation: Snow Rails Drop in From The Top

-

Mill Finish, Powder Coat, or Slide in a 2" Color Strip

Custom Design Assistance Available

We will provide a free custom design and quote for your SnoBar system. Begin the process by submitting the Quote Request Form, or call us at 1-800-SNOJAX-1 (800-766-5291) with any questions. Sample Bar Kits for submittal purposes are available for purchase.

RCB-3 ColorBar Submittal Documents

ColorBar RCB-3 Important Disclaimer:

Do not install this snow retention system on isolated roof areas, just over doorways, stack pipes, chimneys, or partial roof sections. Upper roofs, if any, must not be allowed to shed snow and ice onto lower roof areas with snow bars. Before using this product on lower roof areas, all upper roof areas must have a snow retention system. Never install a snow bar system beyond where the end wall and overhang connect. Always obtain a manufacturer's quantity and spacing recommendation before purchasing and installing this product. The installer of this system must carefully follow the manufacturer's installation and spacing recommendations. Not following the manufacturer's spacing and installation recommendations may result in severe roof panel damage, personal injury, or even death.