SnoBar Roof Clamp Bracket Mounted With RoofClamp RCT

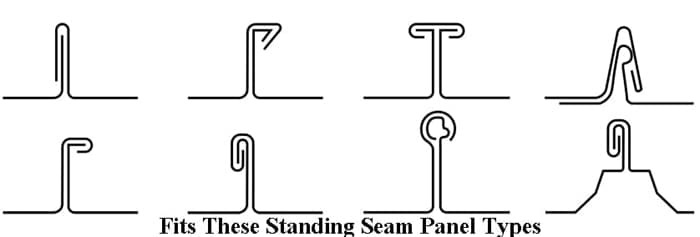

The SnoBar® snow retention systems prevent rooftop avalanches that can damage gutters, HVAC units, cars, and expensive landscaping. The SnoBar® RCB-3 (3-inch Roof Clamp Mounting Bracket) fits more standing seam roof panel profiles (see clamp comparison) than our standard stainless steel bar clamp. The RoofClamp RCT features a cut-out that fits most T-seam and bulb-seam metal roofing panel profiles. The snow bars on the RCB-3 mounting brackets are securely attached to the standing seam panels using the patented aluminum RCT RoofClamp and three stainless steel cup-tipped set screws. The top-loading RCB-3 features fast installation. RCB-3 SnoBar® systems are compatible with most standing seam roof systems.

SnoBar RCB-3 Bracket Swivels 31 Degrees

The RCB-3 SnoBar mounting bracket features a swivel capability that makes it perfect for attaching the SnoBar snow retention system in areas such as hips and valleys. With a width of 3 inches, this bracket offers a full 31 degrees of swivel, enabling snow bars to be positioned strategically on roof areas where other snow bar systems may not fit. The SnoBar® mounting brackets also offer a practical solution for installing snow bars in a clean, straight line across the roof.

Install IceStoppers over Pedestrian Walkways and Parking Lots

IceStoppers serve as a crucial deterrent against the dangers of snow and ice sliding beneath the snow bars. IceStoppers are fixed to the snow rail and do not require feeding through the bar. This innovative snow guard solution for snow rails aims to protect individuals from potential injuries, which could, in severe cases, be life-threatening.

Clamp-on SnoBar is Safe for Standing Seam Metal Roofs

This product is perfect for standing seam metal roofs with its one-piece aluminum clamp featuring three non-penetrating cup-tipped set screws. The top-loading drop in the mounting bracket means there is no feeding the brackets through the bar like other snow rail systems. This standing seam-mounted SnoBar® rail design runs the length of the roof and ensures no risk of damaging roof seams with screws or holes.

Snow Bars With RCT RoofClamps Have Great Strength and Durability

SnoBar® features a Gatorshield®-coated bar that offers great strength and durability. This product also features three super strong "cup-tipped" stainless steel screws, not one or two slippery "round nose" screws. The cup-tipped set screws require significantly less torque, resulting in reduced panel dimpling. The SnoBar® and aluminum roof clamps are guaranteed as long as the roof.

SnoBar With The RCB-3 Mounting Brackets are Fast and Easy to Install

Exclusive low-torque aluminum roof clamps and aluminum top-loading brackets make this the fastest bar system to install in the industry. Fewer parts mean quicker installation times with less labor!

Custom Design Assistance is Available

We will provide a free custom design and quote for your SnoBar® system. To begin the process, submit the Quote Request Form or call us at 1-800-SNOJAX-1 (800-766-5291) with any questions. Sample Bar Kits for submittal purposes are available for purchase.

RCB-3 (Roof Clamp Bracket 3-inch) Mill SnoBar Features:

-

Bars and Clamps Can be Powder Coated To Match The Panel

-

RCT Clamp Fits Most panel profiles, Including Bulb Seam and T Seam Panels

-

RCB-3 Brackets Swivel up to 31 Degrees in Converging Hips and Valleys

-

Can Be Installed At Any Time of The Year

-

No Bar Feeding With Top-Loaded Mounting Brackets

RCB-3 Mill SnoBar Submittal Documents

SnoBar® RCB-3 Important Disclaimer:

Do not install this snow retention system on isolated roof areas, just over doorways, stack pipes, chimneys, or partial roof sections. Upper roofs, if any, must not be allowed to shed snow and ice onto lower roof areas with snow bars. Before using this product on lower roof areas, all upper roof areas must have a snow retention system. Never install a snow bar system beyond where the end wall and overhang connect. Always obtain a manufacturer's quantity and spacing recommendation before purchasing and installing this product. The installer of this system must carefully follow the manufacturer's installation and spacing recommendations. Not following the manufacturer's spacing and installation recommendations may result in severe roof panel damage, personal injury, or even death.