Buy w/Stainless ClampBuy w/Aluminum ClampBuy Screw Down SnoBar

- Made in America

- Laboratory and field tested

- It can be installed year-round

- Easy installation

- Available in galvanized steel, stainless steel, or powder coated to match

SnoBar is a snow retention system available in 16-gauge galvanized mill finish or stainless steel; both options offer superior corrosion resistance. SnoBar can also be color-matched by powder coating both bars and clamps. Snobar systems can be designed for most roof panels with either non-penetrating stainless steel clamp attachments or aluminum screw-down brackets.

Safe for Roofs

This product is perfect for standing seam metal roofs with its one-piece, top-loading stainless steel clamp. This continuous bar design runs the length of the roof and ensures no risk of damaging roof seams with screws or holes. SnoBar prevents rooftop avalanches that can lead to damaged gutters, HVAC units, cars, patios, and even injuries.

Unmatched Strength and Durability

SnoBar features a design that is available in either 16-gauge galvanized steel or stainless steel construction and offers unbeatable strength and durability. The product also features super strong "cupped tipped" stainless steel screws, not slippery "round nose" screws. The strength of this product has been proven in both laboratory and field testing.

Simple and Fast Installation

Exclusive top loading clamps and brackets make this the industry's fastest-installed system. Fewer parts means less labor!

Includes Custom Design

We will provide a free custom design and quote for your SnoBar system. Begin the process by submitting the Quote Request Form, or call us at 800-766-5291 with any questions.

Buy w/Stainless ClampBuy w/Aluminum Clamp

The following warranty is made in lieu of all other warranties expressed or implied. Recommendations for proper use of the product are based on tests believed to be reliable. Any goods proven to be defective due to materials will be replaced, or purchase price refunded, but in no event shall the manufacturer be responsible for damages in excess of the purchase price. User shall determine the suitability of the product for its intended use and assumes all risks of its use or handling.

1. All loads incurred by the SnoBar will be transferred to the panels. Therefore, proper panel attachment to substrate/structure is necessary to prevent roof panels from sliding under snow load. New and existing structures must be evaluated to insure they can withstand retained snow loads. (In instances where there is an overhang at the eave edge, it is imperative to make sure that the overhang can hold the accumulated loading, otherwise the first row of SnoBar should occur at the bearing wall.)

2. It is not recommended to place the SnoBar System in isolated areas such as doorways, vents and partial roof areas. Please call for special design considerations in those areas.

3. Consider whether your roof system and/or substrates (felts or membranes) run the risk of ice damming with the addition of this type of system.

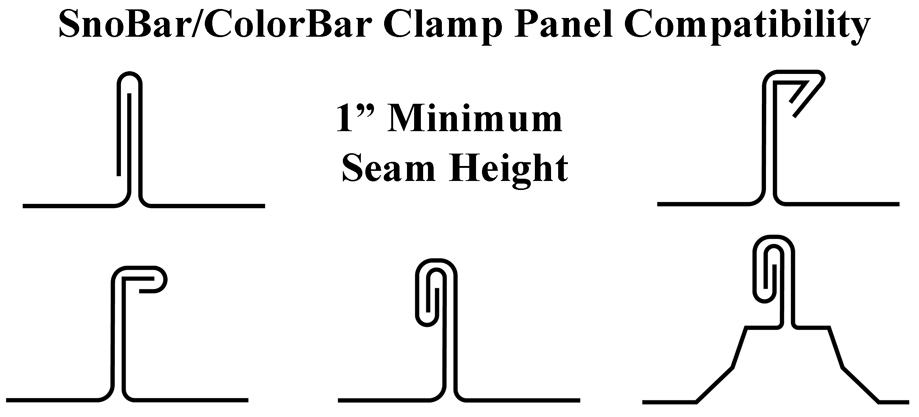

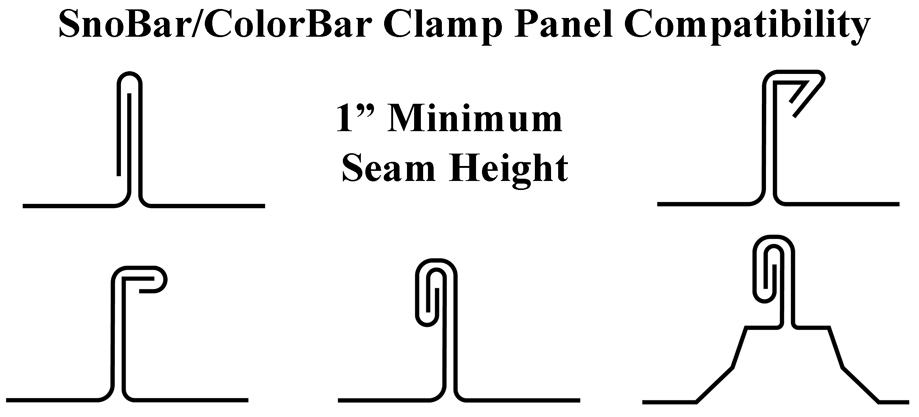

4. The SnoBar Clamp System requires the roof panel to be a min. of 24 GA. steel and have a seam height of at least 1". Clamp spacing cannot exceed 24"O.C. Clamp spacing varies dependign on seam spacing (12" o.c. up to 42" o.c). Clamps should be placed at every seam, so that the load is distributed evenly to every roof panel. It is not recommended to use a clamp type system when the roof uses a seperate seam cover or batten.

5. The U-Bracket System requires a purlin or structural support beneath it to mount to.

6. No snow retention system is capable of retaining 100% of snow and ice from falling off the roof.

7. Designer/Arhitect, Installer, or Owner of the project should have knowledge of the local snow loads, climatic conditions, roof slope, roof orientation, and roof design prior to installing SnoBar.

8. After considering the above factors, the determine lineal feet of SnoBar required is based on length of panels, roof slope, snow loading and areas needing protection from falling snow. (Call SnoBlox-SnoJax for clamp and bar loading values.)

9. It is the sole responsibility fo the Designer/Architect, Installer, or Owner to assess the suitability of using the SnoBar System based on the above design considerations. SnoBlox-SnoJax or any or its subsidiaries, or Riddell & Company, Inc and Action Manufacturing are under no liability if failure occurs from improper installation, improper set screw torque, improper panel attachment, improper roof system installation, improper use of the SnoBar system or under designed system placement of the SnoBar system.

This is a special-order item, thus All Sales are Final. Sorry, no returns accepted.