Snow Guards for AllSteel Inc. Exposed-Fastener Steel Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Oct 6th 2025

See the Snow Guards Compatibility Chart for AllSteel Screw Down Metal Roofing Panels.

Which snow retention systems are best suited for AllSteel Inc.'s exposed-fastener metal roofing?

Metal roofs with exposed fasteners are particularly prone to sudden snow and ice slides during winter months, often referred to as rooftop avalanches.

The smooth surface of metal panels allows snow and ice to accumulate and then release unexpectedly, creating potential hazards for people, pets, and property below. To help prevent these incidents, we designed our snow retention solutions to work with a wide range of roof designs and materials. Customers can tailor our snow guards and rail systems to accommodate different panel profiles, roof slopes, and regional weather conditions. We also provide helpful resources like our blog posts, installation guides, and updated compatibility charts for top roofing brands. In areas with consistent or heavy snowfall, these systems play a critical role in controlling how and when snow and ice shed from the roof.

AllSteel Inc.: Exposed-Fastener Metal Roofing

The industry recognizes AllSteel Inc. for its reliable service and premium sheet metal offerings. Led by Mike Batterton and Jason Guffey, the company employs a skilled team of 35 professionals dedicated to producing long-lasting, cost-effective solutions. Since its launch in 2006, AllSteel has grown from a small operation into a thriving manufacturer with three facilities strategically located in Arkansas and Missouri. One of AllSteel's standout features is its commitment to in-house fabrication. By avoiding outsourcing, the company maintains strict quality control, ensuring that each product aligns precisely with project requirements. Their extensive inventory includes not only sheet metal but also culverts, beams, steel purlins, and insulation products like Solar Guard, 2" VRR, and 3" VRR. This wide selection makes AllSteel a trusted partner for contractors, builders, and property owners alike. What sets AllSteel apart is its strong regional footprint, serving North Central Arkansas and Southern Missouri as the only local manufacturer in the area. This proximity translates to quicker delivery times, greater flexibility, and the confidence that comes from sourcing materials from a nearby, reputable supplier.

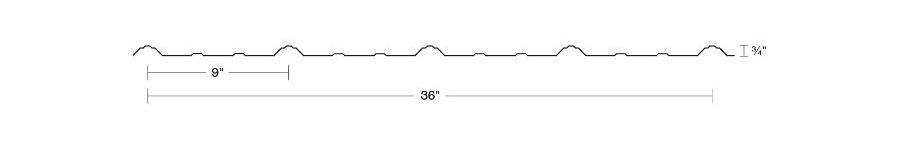

Tuff Rib Panel

The Tuff Rib Panel features a traditional exposed-fastener profile with a 36-inch coverage width and 3/4-inch rib height, spaced 9 inches apart. It's available in 29 and 26-gauge steel, with finish options including painted and acrylic-coated Galvalume. Designed for both residential and commercial applications, it supports roof slopes as low as 3:12. It can be installed over either open framing or solid decking, providing a versatile solution. This panel meets rigorous standards, including UL 2218 Class 4 for impact resistance, UL 790 Class A for fire safety, UL 580 Class 90 for uplift resistance, ASTM E455 for diaphragm strength, and approvals from Texas Windstorm, Florida Building Code, Miami-Dade County, and ICC ESR-2385. See the Snow Guards Compatibility Chart for AllSteel Tuff Rib Screw Down Metal Roofing Panels.

This panel works seamlessly with a variety of our snow retention products, offering installation versatility across multiple substrates. Polycarbonate models, such as the SnoBlox Deuce and SnowBreaker, are designed to nest between the minor ribs. Metal options such as the SnoCleat PBR and all six SnowCatcher styles use screws to attach to the flat center section. Other designs, including the Snojax I and Icejax I, span the minor ribs. The Icejax I supports both adhesive and screw installation, while the Snojax I requires mechanical fastening only. The panel also pairs well with Tall ColorBrackets, which are compatible with aluminum ColorBar PBR or galvanized SnoBar PBR rail systems. This adaptability makes the Standard Tuff Rib Panel a dependable choice for snow control across diverse climates.

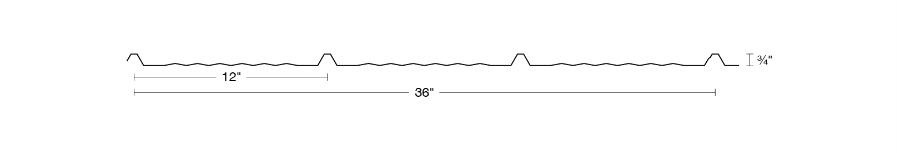

Apex Panel

The Apex Panel combines sleek visual appeal with practical installation, offering the look of a standing seam system at the cost of a through-fastened design. It features four ribs, each 3/4" high and spaced 12" apart, covering a total width of 36". Panels are custom-cut to lengths of 3 to 40 feet and are available in 29- and 26-gauge Galvalume steel. Ideal for residential and light commercial projects, this product features an anti-siphon groove for enhanced water resistance and supports roof slopes as low as 3:12. Apex panels come with a 50-year paint warranty and a 45-year Galvalume warranty. They are compatible with both solid decking and open framing. See the Snow Guards Compatibility Chart for AllSteel Apex Screw Down Metal Roofing Panels.

This panel supports a wide range of snow guard systems, accommodating various installation styles and environmental conditions. Stainless steel pad-style guards, such as the SnowCatchers in Standard, Sun Burst, Maple Leaf, Fleur-de-lis, Kodiak, and Mustang designs, can be securely mounted. Polycarbonate models like the SnoBlox Deuce, Icejax II, and SnoBlox Ace offer flexible installation with either adhesive or screws. The Snojax I, however, must be mechanically fastened and is not suitable for adhesive mounting. For those looking to break up snow and ice into smaller, safer pieces, the SnowBreaker and SnowBreaker 3M systems offer effective control. In high snow-load areas (above 45 PSF) or for customers seeking a modern aesthetic, rail systems like SnoBar and ColorBar provide a strong solution. These systems use Tall ColorBrackets with butyl tape gaskets for a secure and clean finish. Due to the panel's striated texture, installers may need to apply extra adhesive or sealant to ensure proper bonding.

PBR Panel

The PBR (Purlin Bearing Rib) Panel is a robust solution tailored for agricultural, commercial, and industrial structures. It features deep trapezoidal ribs with intermediate minor ribs for added reinforcement, offering 36 inches of coverage and enhanced diaphragm performance with major ribs on 12" spacing. AllSteel's version is available in 26 gauge and comes in standard, crinkle, and Tru-Steel HD digital finishes. These panels are certified for both roof and wall use. AllSteel recommends them for low-slope installations, with documentation supporting their structural and aesthetic warranties. See the Snow Guards Compatibility Chart for AllSteel PBR Screw Down Metal Roofing Panels.

This panel is compatible with a wide range of snow retention systems, enabling customized solutions tailored to individual installation preferences and local climate conditions. Stainless steel pad-style guards, such as the SnowCatcher series in Standard, Sun Burst, Maple Leaf, Fleur-de-lis, Kodiak, and Mustang styles, can be securely attached to the panel surface. Polycarbonate options such as the SnoBlox Deuce, Icejax II, and SnoBlox Ace support both adhesive and screw mounting. The Snojax I must be mechanically fastened and is not suitable for adhesive installation. For snow fragmentation, the SnowBreaker and SnowBreaker 3M systems offer reliable performance. In regions with snow loads exceeding 45 PSF or for those seeking a streamlined appearance, rail systems like SnoBar and ColorBar provide a durable and visually appealing solution. These systems use Tall ColorBrackets with butyl tape gaskets for a secure fit. Due to the panel's textured surface, installers may need to apply a thicker adhesive or sealant layer to ensure proper adhesion.

AllSteel Inc. Compatibility Chart for Snow Guards

| Tuff Rib Panel | Apex Panel | PBR Panel | |

|---|---|---|---|

Ecojax |

YES | YES | YES |

IceJax I |

YES | YES | YES |

IceJax II |

NO | YES | YES |

SnoBlox Deuce |

YES | YES | YES |

Ace |

NO | YES | YES |

Snojax I |

NO | YES | YES |

Snojax II |

NO | YES | YES |

SnowBreaker |

YES | YES | YES |

SnowCatcher |

YES | YES | YES |

SnoBar PBR |

YES | YES | YES |

ColorBar PBR |

YES | YES | YES |

SnoCleat PBR |

YES | YES | YES |

SnoCleat 2.67 |

NO | YES | NO |

SnoBar 2.67 |

NO | NO | NO |

ColorBar 2.67 |

NO | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by AllSteel Inc.

How Can I Fasten Snow Guards for Maximum Strength?

To ensure a secure hold, attach snow guards directly to structural elements, such as purlins or rafters, rather than just the roof panels. Strengthening the mounting area or using both adhesive and screws can boost load capacity and overall durability.

Should I Test Fit Snow Guards Before Final Installation?

Doing a preliminary layout of your snow guards before final installation helps confirm proper spacing and alignment. This step allows for quick corrections and contributes to a cleaner, more professional finish.

Should I Apply Sealant Under Screw-Mounted Snow Guards?

Applying a thick layer of sealant beneath screw-mounted polycarbonate guards helps seal gaps, enhance waterproofing, and reduce the likelihood of leaks over time. This extra step reinforces the installation and improves long-term performance.

How Does Roofing Material Affect Snow Guard Placement?

The type of roofing material plays a key role in determining snow guard spacing and layout. Softer metals, such as copper or aluminum, may require tighter spacing and multiple rows, whereas harder surfaces, like steel, can accommodate wider intervals. Always check that adhesives and sealants are compatible with the roof finish to avoid damage or bonding issues.

What Snow Guard Solutions Work Best for Unique Roof Shapes?

Roofs with unconventional shapes, such as curved or arched designs, often require specialized snow guard solutions. Standard models may not fit properly, so it's best to choose guards tailored to the roof's geometry and consult the manufacturer for guidance.

How Can I Coordinate Snow Guard Finishes with My Roof Design?

Select finishes that harmonize with your roof’s color and architectural style. Powder coating and custom inserts can elevate the visual appeal and help the guards blend seamlessly with the roof surface. Professional coatings offer extended durability, while DIY options provide quicker results at a lower cost.

When Is the Best Time to Install Adhesive Snow Guards?

The ideal time to install adhesive-mounted snow guards is during warmer weather, typically late spring to early summer, when daytime temperatures stay above 50°F. Warm conditions support proper curing, while cold temperatures can delay the process. Products like SureBond SB-190 usually become moisture-resistant within 24 hours, helping minimize weather-related setbacks.

Conclusion

At SnoBlox-Snojax, we build our snow guard systems for lasting performance, not temporary solutions. We've built strong customer relationships by offering transparent product details, easy-to-follow installation guidance, and attentive support from start to finish. Resources like our comprehensive Snow Guard Buyer's Guide and step-by-step installation manual empower customers to make well-informed decisions with confidence. Whether by phone or email, our knowledgeable team is ready to provide tailored assistance and help with any order-related questions. Our dedication to dependability and customer satisfaction ensures that selecting, installing, and maintaining snow retention systems is a smooth experience, supported by trusted products and expert advice every step of the way.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.