Snow Guards For Coated Metals Group Exposed Fastener Steel Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Sep 17th 2025

See the Snow Guards Compatibility Chart for Coated Metals Group Screw-Down Metal Roofing Panels.

Which snow guards work best with Coated Metals Group's exposed-fastener steel roof panels?

Metal roofs with exposed fasteners are prone to sudden slides of snow and ice in winter.

The smooth surface of metal roofs often leads to snow and ice sliding off quickly, creating potential hazards for people, pets, and property below. To help minimize these dangerous avalanches, our snow retention solutions are designed to work with many different roof types and materials. Customers have the option to tailor our snow guards and rail systems to match various panel designs, roof slopes, and weather conditions. We also provide helpful resources, including blog posts, installation guides, and current compatibility charts for major roofing brands. In areas that experience regular or heavy snowfall, these products play an important role in controlling and safely managing the release of snow and ice throughout the winter.

Exposed Fastener Metal Roof Panels by Coated Metals Group

Coated Metals Group (CMG) is a leading manufacturer of pre-finished steel products, specializing in high-quality standing seam roofing panels. Founded in 1983 by brothers Gary and Scott, the business began as a small, family-owned operation and has since grown into a nationally recognized company renowned for its exceptional products and customer-focused approach. The company is based in Verona, Wisconsin, and has expanded to operate production and distribution centers in multiple locations, including Madison, Wisconsin; Denver, Colorado; Indianapolis, Indiana; Phoenix, Arizona; Minneapolis, Minnesota; Salt Lake City, Utah; Nashville, Tennessee; Charlotte, North Carolina; and Bozeman, Montana. Each facility is equipped with advanced technology to deliver consistent quality and dependable service. CMG also emphasizes product durability, offering finishes backed by one of the strongest warranties in the market. The dedication of its employees has been central to its growth, and in 2016, Gary and Scott transitioned the company to full employee ownership. This change strengthened a culture of pride and accountability, with every employee-owner helping to uphold CMG's standing as an industry leader.

Ultra 7.2 Box Rib Panel

CMG's Ultra 7.2 Box Rib panel is built for strength and bold aesthetics, making it a go-to choice for commercial, agricultural, and contemporary residential projects. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra 7.2 Box Rib Screw Down Metal Roofing Panels. Its 7.2-inch rib spacing and 1.5-inch rib height create a striking industrial profile that performs as well as it looks. Designed for versatility, it can be mounted vertically or horizontally across walls, roofs, soffits, and fascias. The panel is available in 22- to 26-gauge steel and comes in finishes including pre-painted steel, Galvalume, and A606 Corten. What sets this panel apart is its rigorous testing: it meets UL 580 Class 90 standards for wind uplift, UL 2218 Class 4 for hail impact resistance, and UL 790 Class A for fire safety. It also complies with ASTM E283, E331, and E330/E330M, covering air leakage, water penetration, and structural load performance—making it a reliable solution for demanding environments.

The Ultra 7.2 Box Rib Panel works with a range of snow management products designed to control snow and ice on rooftops. The polycarbonate SnoBlox Deuce functions as a pad-style guard, helping to keep snow and ice in place. At the same time, the SnowBreaker breaks them into smaller, safer sections as they slide off. You can mount these snow guards using screws or adhesive, with the SnowBreaker 3M also offering installation through 3M double-sided tape. In addition, the Ultra 7.2 Box Rib Panel is compatible with the galvanized SnoBar and aluminum ColorBar rail systems, both of which attach using the 1.5-inch wide aluminum Tall ColorBracket to create a secure and efficient snow retention solution.

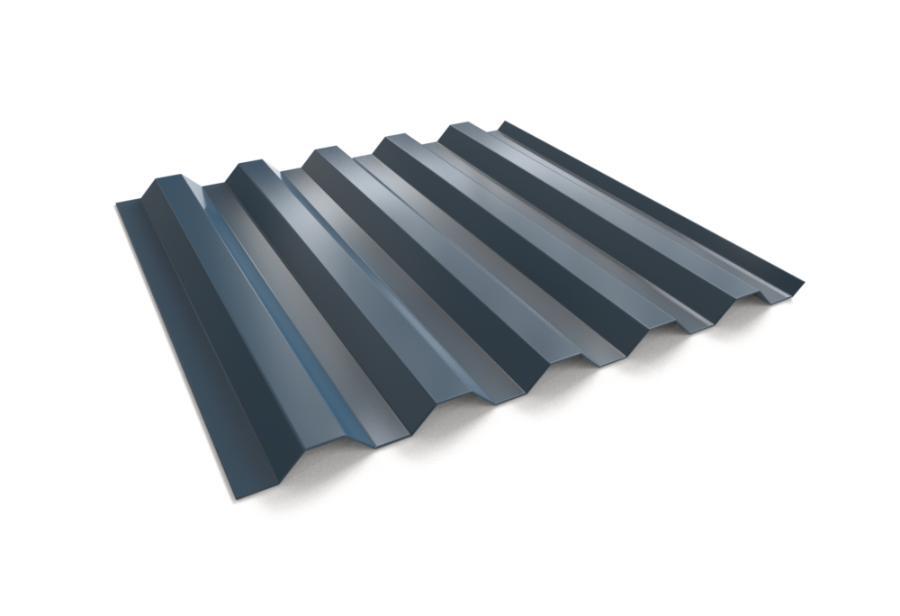

Ultra-Corrugated Panel

The Ultra-Corrugated panel from CMG offers a timeless wave-like profile that adds texture and visual rhythm to any architectural surface. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Corrugated Screw Down Metal Roofing Panels With ribs spaced 2.67 inches apart and standing at 7/8 inch high, this panel delivers a clean, classic look suitable for both modern and traditional designs. This panel is flexible—installable over open framing or solid substrates, and adaptable for vertical or horizontal layouts. Available in a range of finishes like Galvalume Plus, Bonderized, and weathered A606 Corten steel, it comes in 22 to 26 gauge options depending on the selected material. While CMG doesn't list specific certifications for this panel on their site, they do offer full testing data and structural specs upon request, ensuring it meets professional standards for durability and performance.

The Ultra-Corrugated Panel features a distinctive wavy corrugated profile that sets it apart from traditional exposed fastener roofing systems. This unique design permits snow guards to be installed on the raised ribs, differing from standard roofing practices. For those seeking snow retention options, the Ultra-Corrugated Panel is compatible with several of our products. You can mount the SnoCleat 2.67 to the ribs with 3-inch screws. At the same time, the SnoBar and ColorBar systems are also suitable choices, both using the same ColorBracket 2.67 as the SnoCleat 2.67. Each ColorBracket 2.67 contains six screw holes for added mounting strength, though only four screws are required. In areas with more severe weather, utilize all six screws to ensure a stronger and more reliable installation.

Coated Metals Group Compatibility Chart for Snow Guards

| Ultra 7.2 Box Rib Panel | Ultra-Corrugated Panel | |

|---|---|---|

Ecojax |

YES | NO |

IceJax I |

NO | NO |

IceJax II |

NO | NO |

SnoBlox Deuce |

YES | NO |

Ace |

NO | NO |

Snojax I |

NO | NO |

Snojax II |

NO | NO |

SnowBreaker |

YES | NO |

SnowCatcher |

NO | NO |

SnoBar PBR |

YES | NO |

ColorBar PBR |

YES | NO |

SnoCleat PBR |

NO | NO |

SnoCleat 2.67 |

NO | YES |

SnoBar 2.67 |

NO | YES |

ColorBar 2.67 |

NO | YES |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Coated Metals Group

Attach Snow Guards to Structural Supports

For lasting strength, fasten snow guards directly into structural elements such as rafters or purlins rather than relying solely on roofing panels. Reinforcing supports when needed or combining with the right adhesives can further improve durability.

Apply Sealant Under Screw-Mounted Guards

When installing polycarbonate guards with screws, apply a generous layer of sealant underneath before securing. This practice helps close gaps, enhances waterproofing, and reduces the potential for leaks over time.

Install Adhesive Snow Guards in Warm Conditions

Plan adhesive-mounted installations for warmer months, preferably late spring to early summer, when temperatures remain above 50°F for consecutive weeks. Proper curing depends on heat, while cold can extend cure times. Adhesives like SureBond SB190 generally resist moisture within a day, lowering weather-related concerns.

Seek Specialized Guard Solutions for Unusual Roof Shapes

On arched, curved, or unique architectural roofing, standard guards may not be effective. Choose snow retention products designed for these shapes and confirm with the roof manufacturer that the solution is suitable before installation.

Place Snow Guards According to Roofing Material

How you position and space snow guards depends on the type of roof material. Softer metals such as aluminum or copper often require closer spacing and additional rows, while stronger options like steel may not. Always ensure the guard is chemically compatible with the roofing finish.

Coordinate Snow Guard Finishes with Roof Design

Pick finishes that enhance the overall style and shade of your roof. Powder coating or custom inserts can improve appearance while blending seamlessly. Professionally finished options typically offer greater longevity, though do-it-yourself methods may be faster and more economical.

Test Snow Guard Positioning Before Final Attachment

Lay out the guards across the roof before permanent installation to confirm proper spacing, fit, and alignment. This preliminary step makes it easier to adjust placement for both effective performance and a uniform look.

Conclusion

SnoBlox-Snojax offers snow guard systems built for long-lasting performance rather than temporary fixes. Our company has earned the trust of our customers by providing clear product details, straightforward installation instructions, and attentive support. Resources like our Snow Guard Buyer's Guide and comprehensive installation manual give customers the information needed to make confident choices. Additionally, reach out to our team by phone or email to provide personalized guidance and assistance with orders. With a strong focus on reliability and service, SnoBlox-Snojax makes it possible for customers to select, install, and maintain their snow guard systems with assurance, backed by durable products and expert assistance.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.