Snow Guards for Standing Seam Steel Roofs by Coated Metals Group

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Sep 15th 2025

See the Snow Guards Compatibility Chart for Coated Metals Group Standing Seam Metal Roofing Panels.

Which styles of snow guards are most effective for standing seam steel roofs from Coated Metals Group?

During winter, standing seam metal roofs may suddenly shed built-up snow and ice, creating hazards for people, pets, and property beneath.

Managing the risks of roof avalanches begins with selecting appropriate equipment and relying on expert guidance. Homeowners or contractors exploring snow guards and retention systems for concealed fastener roof panels can benefit from tailored advice that meets their specific needs. Through our ongoing blog posts, we support readers in finding products that work with various roofing systems, while also introducing prominent metal panel manufacturers and reliable snow retention choices for each panel style. This comprehensive approach equips readers with the knowledge necessary to make informed decisions, enhance safety, and mitigate the hazards associated with snow and ice accumulation.

Standing Seam Metal Roof Panels by Coated Metals Group

Coated Metals Group (CMG) is a prominent producer of pre-finished steel products, with a strong focus on manufacturing premium standing seam roofing panels. Established in 1983 by brothers Gary and Scott, the company began as a small family-owned business and has since evolved into a nationally recognized leader, renowned for its superior products and customer-first philosophy. Headquartered in Verona, Wisconsin, CMG has grown to include multiple production and distribution facilities across the country, located in Madison, Wisconsin; Denver, Colorado; Indianapolis, Indiana; Phoenix, Arizona; Minneapolis, Minnesota; Salt Lake City, Utah; Nashville, Tennessee; Charlotte, North Carolina; and Bozeman, Montana. Each facility utilizes advanced equipment to ensure reliable quality and timely delivery. CMG's commitment to excellence also extends to its product finishes, which are supported by one of the strongest warranties available, reflecting their durability and lasting performance. The company credits much of its success to the dedication of its workforce. In 2016, Gary and Scott transitioned CMG into a fully employee-owned business. This step has reinforced the company's culture of pride and responsibility, with every employee-owner contributing to its continued reputation as a leader in the industry.

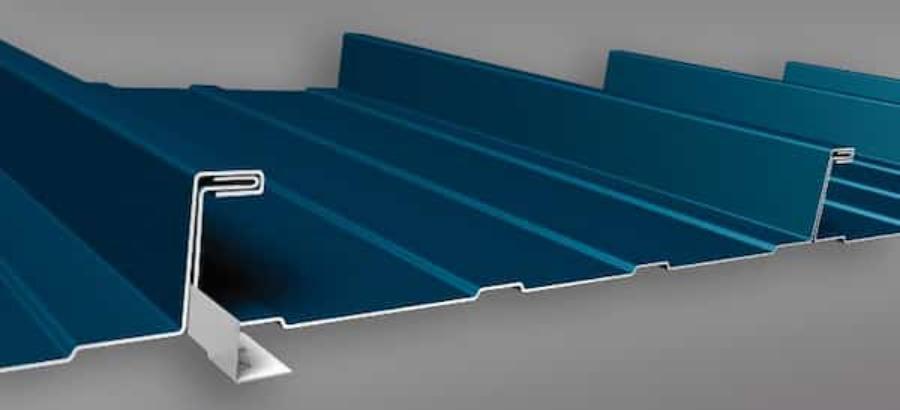

Ultra-Snap Panels

The Ultra-Snap standing seam roof panel system is well-regarded among architects, contractors, and building owners for its combination of visual appeal and ease of installation. Designed with a rigid male/female joint profile, these panels deliver straightforward installation along with strong structural performance. They are UL90 wind uplift rated in multiple assemblies, providing reliable protection against severe weather. The snap-on, one-piece configuration removes the need for mechanical seaming, helping to lower labor costs. With a profile height of 1 3/4 inches, the panels use concealed expansion clips that permit thermal movement while maintaining excellent uplift resistance. Suitable for roof pitches of 3:12 or higher, Ultra-Snap panels are available in 22- and 24-gauge steel or aluminum, with width options of 12, 16, 18, and 22 inches. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Snap Standing Seam Metal Roofing Panels.

This roofing panel pairs well with many of our snow retention systems, especially adhesive-mounted polycarbonate guards. Correct adhesive application is key to dependable performance and avoiding issues caused by moisture or ice. Larger snow guards like the IceJax II, Snojax II, and SnoBlox Ace are suitable options, as are smaller models such as the IceJax I and SnoBlox Deuce. For extra protection against sliding snow and ice, the SnowBreaker and SnowBreaker 3M are also effective. The rib design accommodates clamp-on products, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, which attach using stainless steel SnoBar clamps or aluminum RoofClamp hardware. We advise a trial fit of the clamp to ensure compatibility.

Ultra-Flange 1.0 Panels

The Ultra-Flange 1.0 panel is designed for residential and light commercial projects, providing an appealing architectural profile that combines style with functionality. Its one-piece, clip-less, concealed fastener system streamlines installation, making it a cost-effective choice. By removing the need for separate clips or specialized tools, the design allows quick installation without mechanical seaming. Suitable for roof pitches of 3:12 or greater when applied over a solid substrate, the Ultra-Flange 1.0 is especially popular for mansard and canopy uses where simplicity and efficiency are important. The panel features a 1-inch high seam profile, offered in 24- and 26-gauge steel, with width options of 12, 16, 18, and 22 inches. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Flange 1.0 Standing Seam Metal Roofing Panels.

This panel is a strong match for multiple snow retention methods, with particular effectiveness when paired with polycarbonate guard systems that use adhesive. Proper adhesive application is essential for a secure bond and to help prevent issues caused by moisture or ice accumulation. Larger guard choices, such as the IceJax II, Snojax II, and SnoBlox Ace, as well as smaller versions like the IceJax I and SnoBlox Deuce, can be used. Additional protection is available from SnowBreaker and SnowBreaker 3M, which manage snow and ice movement on the roof. The rib configuration also allows clamp-on installation solutions like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar with stainless steel SnoBar clamps or aluminum RoofClamp fasteners. Checking fit with a clamp beforehand is recommended.

Ultra-Flange 1.5 Panels

The Ultra-Flange 1.5 panel features a slightly higher seam than the Ultra-Flange 1.0, making it a strong option for residential and light commercial projects. With a 1 ½ inch seam height, it preserves the appealing architectural look and simple installation that characterize the Ultra-Flange series. Its one-piece, clip-less construction with concealed fasteners eliminates the need for separate clips or specialized tools, helping to reduce installation time and costs. Designed for use on roof pitches of 3:12 or greater over a solid substrate, the Ultra-Flange 1.5 is available in 24- and 26-gauge steel. Width options include 12, 16, 18, and 22 inches. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Flange 1.5 Standing Seam Metal Roofing Panels.

The compatibility of this roofing panel with snow retention systems is excellent, especially with adhesive-applied polycarbonate guards. A reliable hold relies heavily on correct adhesive application to minimize challenges related to ice or moisture. Both large guards, including IceJax II, Snojax II, and SnoBlox Ace, and smaller guards like IceJax I and SnoBlox Deuce, are appropriate for this panel. To further control snow and ice movement, the SnowBreaker and SnowBreaker 3M offer additional security. Its ribbed design is equally effective with clamp-on systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, which connect with stainless steel SnoBar clamps or aluminum RoofClamp fasteners. Testing a clamp ahead of installation is encouraged to confirm proper attachment.

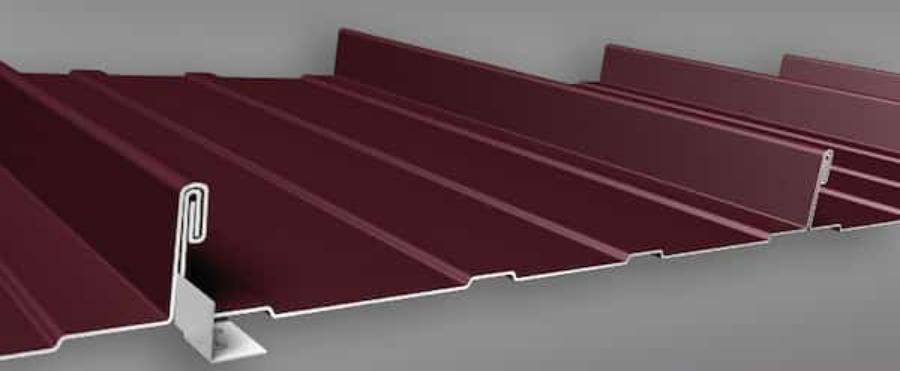

Ultra-Span Panels

The Ultra-Span panel system is designed for projects that demand strong structural support and excellent water tightness, making it well-suited for long roof spans or low-slope designs. It incorporates a mechanically-seamed male/female interlock profile with a deep 2-inch seam height that boosts overall structural strength. The system uses a concealed two-piece clip assembly that accommodates both thermal and structural movement, ensuring durability and maintaining watertight performance. With a UL90 wind uplift rating, it offers reliable protection against severe weather. Ultra-Span panels come in widths of 12, 16, 18, and 24 inches. They are available in 22- and 24-gauge steel as well as aluminum, providing versatility for a wide range of architectural and construction applications. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Span Standing Seam Metal Roofing Panels.

This type of roofing panel works well with a variety of snow retention systems, particularly adhesive-secured polycarbonate guards. For consistent performance, apply adhesive carefully to ensure a strong bond and to prevent moisture- or ice-related concerns. Suitable snow guard options range from larger models, such as IceJax II, Snojax II, and SnoBlox Ace, to compact choices, including IceJax I and SnoBlox Deuce. You can take extra measures, such as SnowBreaker and SnowBreaker 3M, which help manage snow and ice sliding. The rib profile of the panel also supports clamp-on products like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These mounts connect through stainless steel SnoBar clamps or aluminum RoofClamp fasteners, with a trial fit recommended before final installation.

Ultra-Seam Panels

The Ultra-Seam panel system sets the standard for traditional standing seam roofing, recognized for its timeless profile and superior watertight protection. With a mechanically-seamed, double-locked design, it delivers unmatched resistance to air and water infiltration, making it one of the most secure roofing solutions available. The mechanical seaming process ensures exceptional watertight performance, particularly suited for low-slope applications where reliability is critical. Installed over a solid substrate with a minimum underlayment of 30 lb. felt, the system also carries a UL90 wind uplift rating across multiple configurations, guaranteeing strength and durability even in demanding conditions. CMG offers Ultra-Seam panels in 22- and 24-gauge steel or aluminum, with width options of 12, 16, 18, and 24 inches. See the Snow Guards Compatibility Chart for Coated Metals Group Ultra-Seam Standing Seam Metal Roofing Panels.

This roofing panel is well-suited for snow retention applications, especially those that use adhesive-installed polycarbonate snow guards. Achieving a firm hold requires careful adhesive placement, which also guards against issues caused by water or ice. Larger snow guards like IceJax II, Snojax II, and SnoBlox Ace, along with smaller units such as IceJax I and SnoBlox Deuce, are good matches for this panel. For added defense, products like the SnowBreaker and SnowBreaker 3M help slow and control roof slides. In addition, the ribbing of the panel accommodates clamp-on devices, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. Contractors can use stainless steel SnoBar clamps or aluminum RoofClamp fasteners for installation, and it is advisable to check clamp fit beforehand.

Coated Metals Group Compatibility Chart for Snow Guards

| Ultra-Snap Panel | Ultra-Flange 1.0 Panel | Ultra-Flange 1.5 Panel | Ultra-Span Panel | Ultra-Seam Panel | |

|---|---|---|---|---|---|

Ecojax |

YES | YES | YES | YES | YES |

IceJax I |

YES | YES | YES | YES | YES |

IceJax II |

YES | YES | YES | YES | YES |

SnoBlox Deuce |

YES | YES | YES | YES | YES |

Ace |

YES | YES | YES | YES | YES |

Snojax II |

YES | YES | YES | YES | YES |

SnowBreaker |

YES | YES | YES | YES | YES |

SnoBar |

YES | YES | YES | YES | YES |

ColorBar |

YES | YES | YES | YES | YES |

SnoBar RCB-3 |

YES | YES | YES | YES | YES |

ColorBar RCB-3 |

YES | YES | YES | YES | YES |

2 Bar SnoBar |

YES | YES | YES | YES | YES |

2 Bar ColorBar |

YES | YES | YES | YES | YES |

SnoCleat RC |

YES | YES | YES | YES | YES |

SnoCleat RCT |

YES | YES | YES | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by Coated Metals Group

Order sample snow guards to test fit with your roof.

We allow single-unit orders without a minimum. Trying a sample first helps verify compatibility and prevents costly installation mistakes.

Plan layouts that distribute snow evenly.

Arrange pad-style guards in staggered rows, or install bar and rail systems continuously in straight rows according to spacing guidelines, so snow and ice loads are spread evenly.

Account for the snow load rating in your area.

Review local codes for ground snow loads before selecting a system. Pad-style options generally work up to about 45 pounds per square foot, while rail or bar systems handle heavier demands.

Verify compatibility with your roofing type.

Match the guards to your roof profile and materials for reliable performance. Our tools and compatibility charts can assist you in making the right choice.

Apply adhesives at the right time of year.

Install adhesive-mounted guards during warmer months when temperatures are above 50°F, allowing full cure within about 30 days. These become water-resistant within about 24 hours. Do not use Surebond adhesive with copper roofs due to chemical incompatibility.

Incorporate accessories for ice control.

Where sliding ice is a concern, use tools like IceStoppers with rail systems. These prevent sheets of ice from slipping underneath, especially on taller standing seam panels.

Select finishes that suit your roof style.

Pick from powder-coated or custom-color options that complement the look of your roof. On-site finishing may save time and cost, though custom colors can require longer lead times.

Adjust installation around unique roof features.

For roofs with details such as valleys, curves, or complex shapes, modify snow guard spacing and placement to ensure full protection.

Follow warranty-approved installation practices.

For standing seam roofing, opt for non-penetrating methods like clamp-on or adhesive mounting. This practice preserves the roof warranty and avoids possible leaks from fasteners.

Use systems designed for non-standard roof shapes.

Curved or architecturally complex roofs may require specialized snow retention systems. Confirm with the roof manufacturer which configuration is most effective.

Conclusion

SnoBlox-Snojax provides customers with support at every stage of the snow guard installation process by offering tailored guidance and practical resources. Help is accessible through our company’s website, by phone, or via email, making it easy for customers to receive assistance with their specific installation needs. Our Snow Guard Buyer’s Guide helps with choosing the right product, while the Best Practices section identifies common errors to steer clear of. Through clear directions and reliable products, SnoBlox-Snojax gives customers the confidence to carry out their installations, showcasing our company’s commitment to quality service and dependable snow retention solutions.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.