Snow Guards for Standing Seam Steel Roofs by ExSteel Building Components

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Sep 5th 2025

See the Snow Guards Compatibility Chart for ExSteel Building Components Standing Seam Metal Roofing Panels.

Which snow guard options are most effective for standing seam steel roofs manufactured by ExSteel Building Components?

In winter, standing seam metal roofs can abruptly release accumulated snow and ice, posing risks to individuals, pets, and property located below.

To effectively manage the dangers of roof avalanches, it is important to utilize the correct equipment and seek advice from experts. Individuals considering snow guards or retention systems for concealed fastener roof panels can receive recommendations tailored to their unique requirements. Our regular blog posts provide guidance on selecting compatible products for various roofing setups, introduce prominent metal panel brands, and recommend dependable snow retention solutions tailored to each type and brand. By providing this thorough information, we empower our readers to make informed choices that enhance safety and help minimize risks associated with snow and ice buildup.

Standing Seam Metal Roof Panels by ExSteel Building Components

ExSteel, located in Aylmer, Ontario, has established a reputation in the steel construction industry by providing durable roofing and wall systems tailored to Canada's challenging climate. The company's facility produces a comprehensive range of precise products, including the RTL-24 standing seam panel, which is suitable for various residential, commercial, and agricultural applications. ExSteel distinguishes itself by keeping its production processes in-house and consistently following stringent industry standards. They manufacture each item to comply with ASTM A792 guidelines, ensuring lasting quality and uniformity. A dedicated customer support team further enhances this reliability, providing technical assistance and detailed product information. Since its launch in 2004, ExSteel has supplied steel building materials for both new construction and renovation projects throughout North America and beyond, supporting various industries, including industrial, agricultural, recreational, commercial, and institutional sectors. The company's ISO 9001:2015, CSA A660, and CWB certifications demonstrate its dedication to accountability and quality assurance. ExSteel originated as part of Steelway Building Systems, a division of Ardent Industries, which initially produced steel components in-house for pre-engineered buildings. As demand increased, they established ExSteel to provide these products separately to builders, contractors, and suppliers. Today, ExSteel offers solutions that emphasize strength, practicality, and visual appeal, with the RTL-24 panels remaining a favored choice for their adaptability, performance under tough conditions, and dependable craftsmanship.

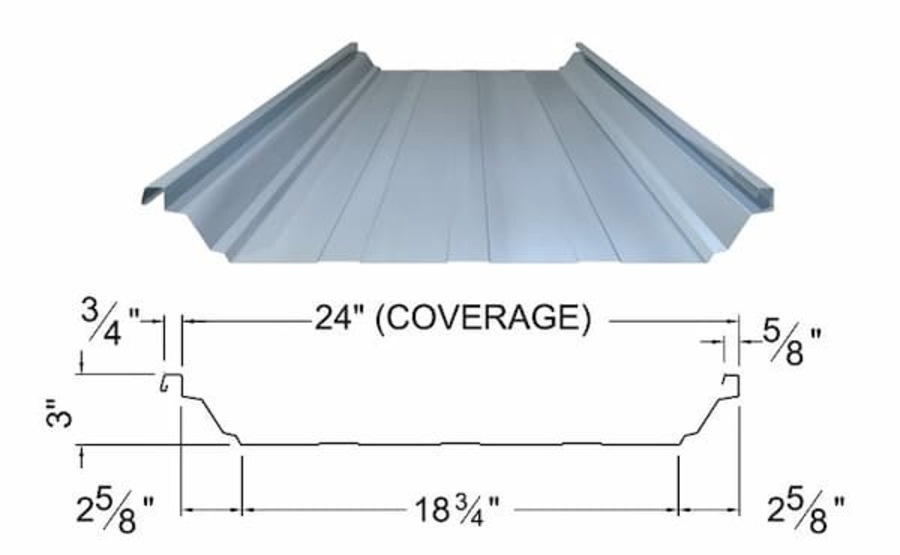

RTL-24 Trapezoidal Panels

ExSteel's RTL-24 trapezoidal standing seam panel offers a blend of structural strength, weather resistance, and modern design, making it ideal for a wide range of applications, from residential to large commercial and agricultural buildings. They produce each panel in 22- and 24-gauge steel, measuring 18.75 inches wide with 24 inches of coverage, with a 3-inch seam height, built to meet ASTM A792 standards, and featuring a 50 ksi yield strength. This robust construction provides lasting durability, enabling the RTL-24 to perform reliably in Canada's most challenging weather conditions. The trapezoidal seam design stands out due to its ability to support heavy loads without needing a solid deck underneath, as its wide seams create rigidity across broader spans, reducing the need for additional structural support while maintaining strength. This design makes it cost-effective for large projects without sacrificing safety or performance. The panel's weather resistance is enhanced by locking seams available in different configurations—RollLoc for normal conditions, TripleLoc for tougher environments, and QuadLoc for areas with high winds—ensuring water tightness even in heavy rain or snow. Concealed fasteners contribute to a clean appearance and eliminate leak risks common with exposed screws. Beyond its functionality, the RTL-24 boasts a sharp architectural profile, featuring trapezoidal ribs that provide a bold and dimensional look, appealing to designers and builders who seek both style and practicality. The panel is also known for its longevity, often lasting 40 years or more with little maintenance, standing up well to cycles of wind, rain, snow, and UV exposure. This durability, combined with low upkeep, makes the RTL-24 a highly cost-effective option over the life of a building. See the Snow Guards Compatibility Chart for ExSteel Building Components RTL-24 Trapezoidal Standing Seam Metal Roofing Panels.

This roofing panel works well with our various snow retention systems, particularly those that use adhesive-mounted polycarbonate snow guards. Proper application of the adhesive is crucial to keep the guards firmly in place and to avoid problems caused by moisture or refreezing. Compatible snow guard models for this panel include larger options like IceJax II, Snojax II, and SnoBlox Ace, as well as smaller versions such as IceJax I and SnoBlox Deuce. For enhanced protection against sliding snow and ice, we recommend the SnowBreaker and SnowBreaker 3M. The panel's ribbed design also supports clamp-on snow retention systems, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These clamps attach using stainless steel SnoBar clamps or aluminum RoofClamp fasteners. Still, it is advisable to test a clamp first to ensure compatibility with the specific panel profile.

ExSteel Building Components Compatibility Chart for Snow Guards

| RTL-24 Trapezoidal Panel | |

|---|---|

| IceJax I Glue Down | YES |

| IceJax II Glue Down | YES |

| SnoBlox Deuce Glue Down | YES |

| SnoBlox Ace Glue Down | YES |

| Snojax II Glue Down | YES |

| SnowBreaker Glue Down | YES |

| SnowBreaker 3M | YES |

| SnoBar Standing Seam | YES |

| ColorBar Standing Seam | YES |

| SnoBar RCB-3 | YES |

| ColorBar RCB-3 | YES |

| SnoBar 2-Bar | YES |

| ColorBar 2-Bar | YES |

| SnoCleat RC | YES |

| SnoCleat RCT | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by ExSteel Building Components

Confirm compliance with local snow load standards.

Before choosing a snow retention system, check local building codes to understand the ground snow load requirements. Pad-style guards generally handle loads up to around 45 pounds per square foot; however, in areas with heavy snowfall, rail and bar systems are preferred.

Use installation methods that align with your roofing warranty conditions.

For standing seam metal roofs, opt for snow guards that attach using clamps or adhesives rather than penetrating fasteners like nails or screws. This approach reduces leak risks and helps maintain warranty protection.

Coordinate adhesive installations with suitable weather.

When installing adhesive snow guards, especially polycarbonate types, plan the work during warm seasons, such as late spring or summer, when temperatures remain above 50°F. Though the adhesive becomes water-resistant quickly, full curing usually takes about 30 days. Avoid applying Surebond SB‑190 on copper to prevent adverse reactions.

Select snow guard systems tailored to your roof profile.

Choose snow guard products that match your roof’s material and profile. Utilize compatibility tools or digital resources to ensure proper fit and long-lasting performance.

Adapt retention strategies for roofs with unique architectural features.

Modify the placement or arrangement of snow guards on roofs with curves or special details to maximize protection during winter.

Incorporate ice control accessories as necessary.

To prevent ice from sliding under bars or causing ice dams, add accessories like IceStoppers—especially on tall-seam metal roofs.

Test products with sample orders.

Order sample pieces of snow guard systems to verify compatibility with the roof design. Samples usually have no minimum order requirements and can help avoid installation errors.

Design guard layouts for even load distribution.

Position snow guards to evenly support snow and ice weight. Stagger pad-style units for balanced coverage and install rail or bar systems continuously, following manufacturer spacing guidelines.

Choose finishes that complement your roof’s appearance.

Select powder-coated or custom-colored finishes that match your roof’s style. While custom coatings may delay delivery, doing the finishing work on-site can save time and costs.

Customize retention for complex roof shapes.

For roofs with unusual lines or curves, use snow retention systems designed specifically for those shapes, and consult the roof manufacturer for recommendations when necessary.

Conclusion

SnoBlox-Snojax offers comprehensive support throughout the entire snow guard installation process by delivering personalized advice and educational materials. Customers can access assistance via our website, phone, or email, allowing them to receive help tailored to their installation requirements. The Snow Guard Buyer's Guide helps users choose the appropriate product, while the Best Practices section points out frequent errors to avoid. By combining straightforward instructions with reliable products, SnoBlox-Snojax empowers our customers to complete their installations with confidence, demonstrating the company’s commitment to quality service and efficient snow retention solutions.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.