Snow Retention Solutions for Metallic Building Systems’ Standing Seam Roofs

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Dec 19th 2025

See the Snow Guards Compatibility Chart for Metallic Building Systems Standing Seam Metal Roofing Panels.

Which snow guard systems are best suited for Metallic Building Systems’ standing seam panels?

Standing seam roofing offers a clean look and strong durability, but it also creates specific safety challenges in cold climates that require proper attention.

When snow and ice release all at once in a large sheet, commonly known as a roof avalanche, they can cause significant damage to property below, from dented vehicles to crushed landscaping, and even pose a risk to people and pets. To mitigate these dangers, installers rely on snow guards and bar-style retention systems designed to match the panel's geometry and attachment method. Since concealed-fastener panels require solutions tailored to their unique profiles, choosing the correct snow retention system is essential for safety, durability, and long-term performance. This blog highlights the snow guard products that pair most effectively with Metallic Building Systems' standing seam panels, helping you make confident, project-ready selections.

About Metallic Building Systems

Metallic Building Systems is a leading provider of custom-engineered metal buildings, recognized for producing durable, high-performance structures with impressive speed, precision, and design versatility. With more than 3.5 million square feet of manufacturing capacity across North America, Metallic combines advanced engineering with a customer-focused process that supports every stage of a project. As a division of Cornerstone Building Brands, the largest exterior building products manufacturer in North America, Metallic benefits from extensive resources, continuous innovation, and a nationwide network of experienced builders and service professionals. Together, these strengths create a streamlined, single-source experience rooted in core values such as safety, integrity, teamwork, and ongoing improvement. Metallic's mission is to deliver dependable, efficient building solutions that support the communities where people live and work.

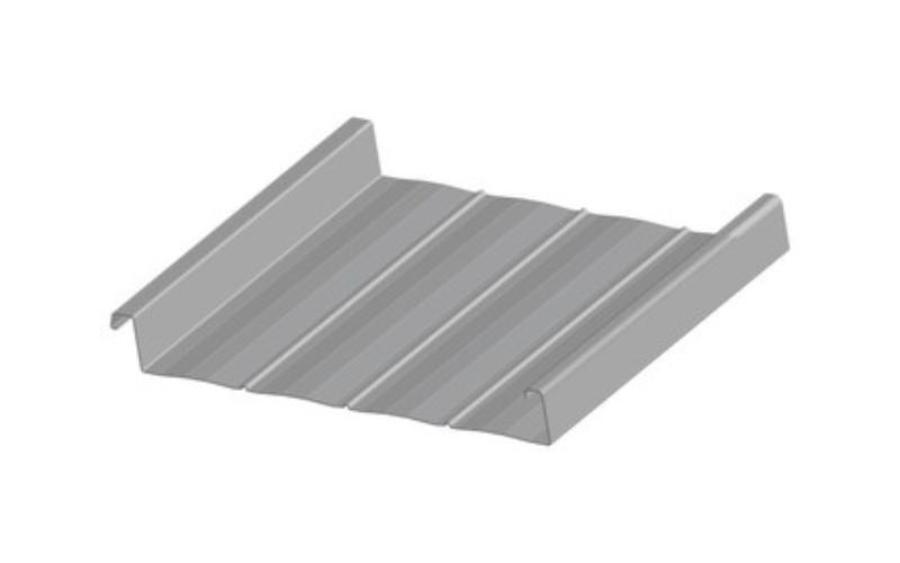

BATTENLOK HS

BattenLok HS is a heavy-duty, field-seamed standing seam roofing system engineered for exceptional strength and adaptability. It features a 2-inch vertical seam and is available in 12-inch and 16-inch panel widths, with a minimum roof pitch of ½:12. The system is available in 22- and 24-gauge steel and can be installed over purlins or bar joists, transitioning smoothly from roof to fascia without the need for a solid deck. BattenLok HS can also be curved in the field, offering added design flexibility.See the Snow Guards Compatibility Chart for Metallic Building Systems BATTENLOK HS Standing Seam Metal Roofing Panels.

This panel is compatible with our clamp-on individual snow guards, including the SnoCleat RC and RCT, as well as our SnoBar and ColorBar snow rail systems. It accepts our standard SnoBar Clamp, RoofClamp RC, and RoofClamp RCT models. Adhesive-mounted polycarbonate snow guards also work well with this profile. Because BattenLok HS comes in two striated patterns, installers may need to apply a slightly thicker layer of adhesive to ensure a complete seal beneath the guard.

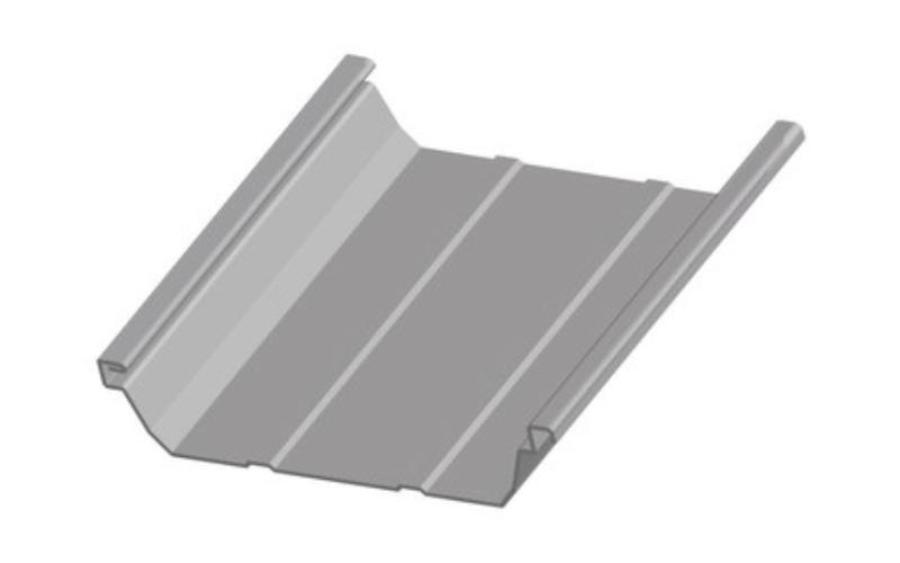

DOUBLE-LOK

Industrial, commercial, and architectural projects widely use the Double‑Lok panel. It is especially effective in retrofit projects where improving energy efficiency and extending roof life are priorities. Metallic Building Systems manufactures Double-Lok in 18-inch and 24-inch widths. This mechanically field‑seamed, trapezoidal‑leg standing seam system uses a 3‑inch rib height and requires a minimum slope of ¼:12. It is available in 22- and 24-gauge steel. See the Snow Guards Compatibility Chart for Metallic Building Systems DOUBLE-LOK Standing Seam Metal Roofing Panels.

Double-Lok is compatible with our clamp-on SnoCleat RC and RCT guards, as well as our SnoBar and ColorBar rail systems. It also accepts our standard SnoBar Clamp, RoofClamp RC, and RoofClamp RCT models. You can also use adhesive‑mounted polycarbonate snow guards. Because this panel includes small minor ribs in the flats, it's important to choose guards that either fit between the ribs, such as the SnoBlox Deuce, or straddle a rib, like the Snojax II or Icejax II.

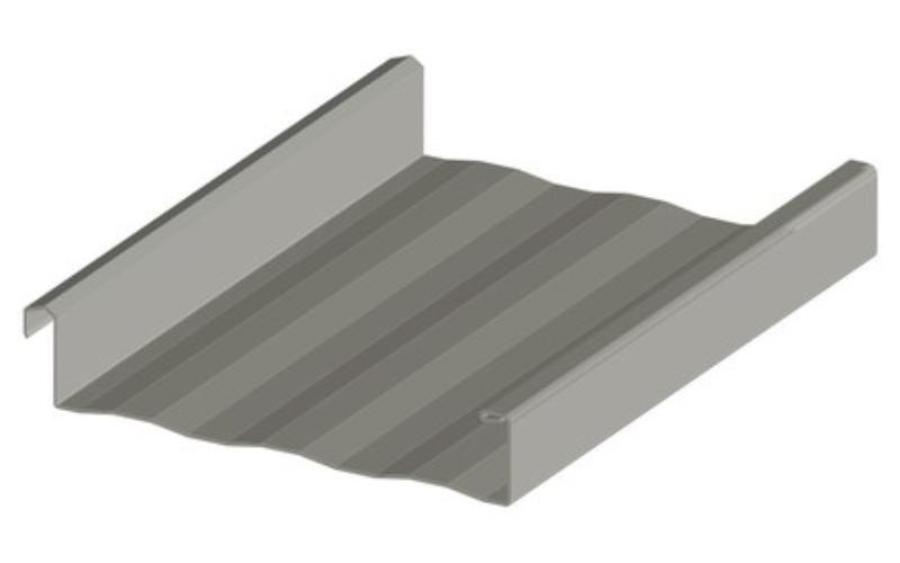

SUPERLOK

SuperLok is a vertical-rib, mechanically field-seamed roof system designed for outstanding uplift resistance. Available in 12-inch and 16-inch widths with a 2-inch rib height, SuperLok performs reliably on roofs with slopes as low as ½:12. It can be installed directly over purlins or bar joists without requiring a solid deck. This panel is available in 22-, 24-, and 26-gauge options. See the Snow Guards Compatibility Chart for Metallic Building Systems SUPERLOK Standing Seam Metal Roofing Panels.

SuperLok is compatible with our full range of clamp-on snow guards, rail systems, and adhesive-mounted polycarbonate guards. Like several other Metallic Building Systems panels, SuperLok includes striations in the flats, so installers should apply adhesive generously to ensure full contact beneath the guard base.

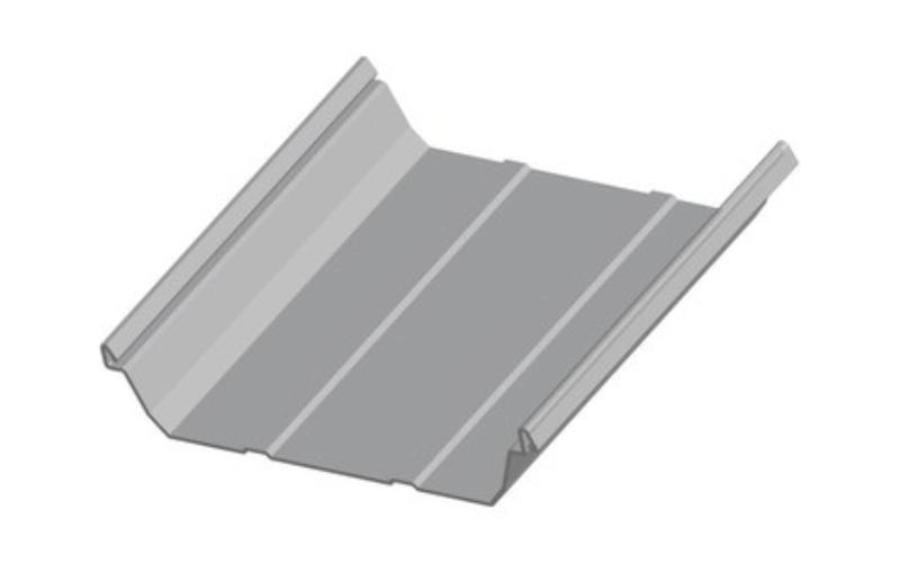

ULTRA-DEK

Ultra-Dek is a snap-together standing seam system with a trapezoidal leg design and proven performance in Air Leakage and Water Penetration testing. Available in 18-inch and 24-inch widths with a 3-inch seam height, Ultra Dek supports a minimum slope of ¼:12 and is offered in 22 and 24-gauge steel. Its versatility makes it suitable for a wide range of industrial, commercial, and architectural applications. See the Snow Guards Compatibility Chart for Metallic Building Systems ULTRA-DEK Standing Seam Metal Roofing Panels.

Dimensionally, Ultra Dek closely resembles the Double Lok panel, with the primary difference being the shape of the upper rib where the panels interlock. Because of this similarity, Ultra-Dek accepts the same snow retention solutions, including clamp-on guards, rail systems, and adhesive-mounted polycarbonate options.

Metallic Building Systems Compatibility Chart for Snow Guards

| Battenlok HS Panel | Double-Lok Panel | SuperLok Panel | Ultra-Dek Panel | |

|---|---|---|---|---|

Ecojax |

YES | YES | YES | YES |

IceJax I |

YES | YES | YES | YES |

IceJax II |

YES | YES | YES | YES |

SnoBlox Deuce |

YES | YES | YES | YES |

Ace |

YES | YES | YES | YES |

Snojax II |

YES | YES | YES | YES |

SnowBreaker |

YES | YES | YES | YES |

SnoBar |

YES | YES | YES | YES |

ColorBar |

YES | YES | YES | YES |

SnoBar RCB-3 |

YES | YES | YES | YES |

ColorBar RCB-3 |

YES | YES | YES | YES |

2 Bar SnoBar |

YES | YES | YES | YES |

2 Bar ColorBar |

YES | YES | YES | YES |

SnoCleat RC |

YES | YES | YES | YES |

SnoCleat RCT |

YES | YES | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by Metallic Building Systems

Verify that guards match your roof design.

Choose snow guards specifically engineered to match your roof's panel profile and material. Using compatibility charts helps prevent mismatches and supports long-term system reliability.

Use systems tailored for unique roof shapes.

Roofs with sharp pitches, curved areas, or unusual geometries may need specialized snow retention solutions. Consult your roofing supplier to identify the most appropriate system for these conditions.

Apply adhesives during the correct weather window.

Install adhesive‑mounted snow guards only when outdoor temperatures remain above 50°F for a continuous 28‑day period. Although the adhesive becomes water-resistant within 24 hours, it takes about 4 weeks to cure fully. Avoid using Surebond SB-190 on copper roofing, as it can accelerate corrosion.

Order sample snow guards for test-fitting.

Samples can be ordered without minimum quantities, allowing installers to test-fit guards directly on the roof. This practice ensures proper alignment and sizing while reducing the risk of installation mistakes. Always follow the manufacturer's instructions to maintain your warranty.

Account for local snow load standards.

Check your local building codes to confirm that your chosen snow retention system meets required snow load capacities. Pad-style guards generally support up to 45 pounds per square foot. Still, regions with heavier snowfall often require stronger rail systems.

Adapt installation for complex roof features.

Snow guard placement may need to be adjusted or customized to accommodate valleys, slope changes, and other unique architectural features. Proper positioning in these areas is crucial to maintain system effectiveness and prevent performance issues.

Conclusion

Our team is here to assist you from the earliest planning stages through the final installation of your snow guard system. Whether you contact us by phone, email, or through our website, you'll receive personalized support designed to keep your project moving smoothly and help you make confident, well-informed choices. To make product selection easier, we offer our comprehensive Snow Guard Buyer's Guide and our Best Practices manual, filled with expert recommendations. These tools help you avoid common pitfalls and approach your installation with clarity and assurance. By combining straightforward instructions, dependable products, and attentive customer service, we help ensure your snow retention system performs exactly as intended. Our dedication to safety, integrity, and reliable support guides every interaction and every project we take on.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.