Snow Guards For Standing Seam Metal Roof Panels by The Bryer Company

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 11th 2025

See the Snow Guards Compatibility Chart for Bryer Company Standing Seam Metal Roofing Panels.

What are the top snow retention options for Bryer Company's standing seam metal roofs?

In winter, structures with standing seam metal roofs frequently face significant problems when snow accumulates and suddenly slips off. This rapid release of snow can pose a risk to people, pets, and property below the roof.

These incidents, known as roof avalanches, underscore the importance of addressing these hazards with specialized solutions and professional guidance. We emphasize snow guards and retention systems designed for concealed fastener roof panels. Customers receive clear, practical advice to assist them in choosing the most suitable snow guard options for their specific requirements, with resources regularly refreshed to ensure users can easily locate products that fit their particular roofing systems. As part of continuous educational initiatives, this blog highlights leading metal panel manufacturers and the snow retention solutions that pair best with their products. This strategy empowers readers to make well-informed decisions, improving safety and minimizing the dangers of sliding snow and ice.

Standing Seam Metal Roof Panels by The Bryer Company

The Bryer Company, established in 1985 and based in Auburn, Washington, is a prominent manufacturer and supplier for the construction industry. They focus on providing architectural and commercial metal roofs, walls, soffit panels, flat sheets, coils, and a full range of related accessories. Bryer is known for offering various component panels, including options in custom colors, heavier gauges, and unique materials. Their product line also features a broad selection of bare, painted, and stainless fasteners for use in sheet metal, mechanical, and metal building projects. They can deliver precise color matches and quick turnaround times with an in-house fastener painting operation. Bryer provides outstanding service and top-quality products to create excellent long-term customer value. The company is also committed to fostering a diverse and inclusive workplace, welcoming people of all backgrounds and believing that such diversity strengthens the organization and aligns with its core values.

TBC-Ultra

The TBC-Ultra roof panel from The Bryer Company is available in 24 and 22-gauge steel, with standard panel widths of 12, 16, and 18 inches and a rib height of 1-3/4 inches. This panel is also available in .032 and .040 aluminum, along with 16 and 20-oz copper options. Designed for architectural performance, this panel features a continuous interlocking seam that provides reliable protection against wind and water intrusion. Its concealed clip system keeps fasteners hidden from view, resulting in a sleek appearance while allowing the panels to expand and contract naturally, contributing to long-term durability. The TBC-Ultra panel is suitable for various uses, including roofing, mansards, fascia, and sidewalls. It performs well in demanding weather conditions. Bryer recommends installation on roofs with a minimum slope of 2:12 and projects with lower slopes. The Bryer Company suggests contacting them for specific recommendations. Technical documents and color guides are available to assist with planning and installation. See the Snow Guards Compatibility Chart for Bryer Company TBC-Ultra Standing Seam Metal Roofing Panels.

These roofing panels are highly adaptable and work well with various snow retention systems, especially those that use adhesive-mounted polycarbonate components. Applying the adhesive correctly is essential to stop moisture from gathering between the snow guards and the panels. Our product lineup features larger options like IceJax II, Snojax II, and SnoBlox Ace, as well as smaller models such as Deuce and IceJax I. For enhanced safety and improved control over snow and ice shedding, we recommend the SnowBreaker and SnowBreaker 3M. The rib design of these panels also supports clamp-on snow guards, including rail systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. While most setups utilize standard stainless steel SnoBar clamps or aluminum RoofClamp alternatives, testing a clamp sample first to confirm it matches your panel style is best.

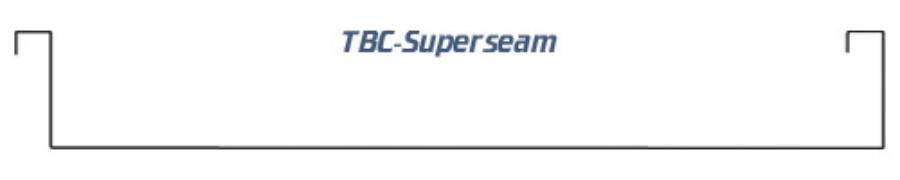

TBC-Superseam

The TBC-Superseam roof panel is available in 12, 16, and 18-inch widths. It can be 22 or 24-gauge steel to suit various project needs. Aluminum and Copper options are also available. Each panel is custom cut to the required length and can be mechanically seamed on site, ensuring a secure and weather-resistant installation. The panel's robust construction and field-seamed design provide excellent protection against air and water infiltration, making it a reliable choice for low-slope roofing applications. It can be installed over a solid substrate, open framing, or rigid insulation, offering flexibility for different building types. With a recommended minimum slope of 1/2:12, the TBC-Superseam panel combines durability, performance, and a clean architectural appearance, making it a preferred option for contractors and architects. Technical resources and additional documentation are available to support installation and specification needs. See the Snow Guards Compatibility Chart for Bryer Company TBC-Superseam Standing Seam Metal Roofing Panels.

These panels suit a wide selection of snow retention solutions, particularly those featuring adhesive-mounted polycarbonate elements. Ensuring the adhesive is applied properly is vital to avoid moisture buildup between the snow guards and the panels. Our product selection includes larger models like IceJax II, Snojax II, and SnoBlox Ace, as well as smaller choices such as Deuce and IceJax I. We advise using the SnowBreaker and SnowBreaker 3M for added safety and improved snow and ice management. The panels' unique rib structure makes them compatible with clamp-on snow guards, including rail systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. Although standard installations often use stainless steel SnoBar clamps or aluminum RoofClamps, trying a sample clamp first is recommended to ensure compatibility with your specific panel.

TBC-Super Curve

The TBC-Super Curve roof panel is available in 22 and 24-gauge steel, as well as .032 and .040 aluminum and 16 and 20-oz copper. The factory can produce panels in lengths up to 80 feet. In comparison, on-site fabrication allows for panels as long as 150 feet, depending on the requirements of the project and shipping limitations. Installers can curve these panels to a minimum radius of 10 feet, making them suitable for distinctive architectural designs. The profile features a flat pan without striations or stiffener ribs, resulting in a modern appearance. The panels come standard with a Kynar 500 or Hylar 5000 finish, with additional options such as Galvalume Plus and stucco embossed finishes. A broad selection of Kynar color choices is also available. The TBC-Super Curve panel is mechanically seamed, providing strength and weather resistance. An optional seam sealant must be applied in the field for optimal performance during the curving process. A 30-year non-prorated finish warranty supports the product and offers up to 25 years of weather-tightness coverage. It also meets several industry standards for wind uplift, fire resistance, impact resistance, water penetration, and air infiltration. Each panel is custom-manufactured to meet the precise needs of every project, ensuring a high level of design flexibility and a clean, contemporary look. See the Snow Guards Compatibility Chart for Bryer Company TBC-Super Curve Standing Seam Metal Roofing Panels.

You should not use individual polycarbonate glue-down snow guards on curved panels or have a radius, such as the one in question, because these snow guards require a flat surface for proper attachment. Instead, it is better to use a clamp-on SnoCleat, SnoBar, or ColorBar snow rail system. These options utilize non-penetrating clamps that secure the seam, preserving the panel's water resistance and preventing corrosion. If the curved panel cannot accommodate a bar system, contacting the manufacturer for guidance is best.

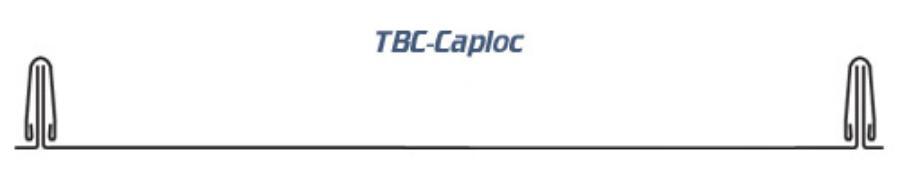

TBC-Caploc

The TBC-Caploc roof panel is a standing seam system designed for various roofing applications. It features a concealed clip mechanism that enables the panels to expand and contract with temperature changes, which helps maintain the roof's durability over time. The panel features a one-inch rib height for the TBC-Caloc and a 1 1/2 1/2-inch high rib height for the TBC-Caploc Plus. These panels are available in 12, 16, and 18-inch width options. This panel system resists harsh weather conditions. It is compatible with roof slopes as low as 3:12. Its versatility makes it suitable for many architectural and commercial projects. This panel uses a separate batten cap for a clean and modern aesthetic. Options are available for this panel in 22 or 24-gauge steel, .032 or .040 aluminum, and 16 or 20-oz copper. See the Snow Guards Compatibility Chart for Bryer Company TBC-Caploc Standing Seam Metal Roofing Panels.

The TBC-Caploc panel utilizes a total coverage batten cap on the ribs, rendering some of our snow retention systems incompatible. Specifically, clamp-on individual snow guards like the SnoCleat RC and SnoCleat RCT and clamp-on snow rail systems like the SnoBar and ColorBar are unsuitable for this panel. The clamps would only attach to the strip itself, failing to provide the correct torque on the main panels. Potential disengagement of the strips from the roof could lead to significant and costly repairs. Fortunately, this panel is compatible with various glue-down polycarbonate snow guard models, including, but not limited to, the SnoBlox Deuce, SnoBlox Ace, IceJax II, and Snojax II. These products retain the snow and ice on the roof, allowing it to melt in place and drain safely into the gutters. SnowBreakers can be an excellent option for those seeking to break the ice and snow into smaller chunks, slowing its release from the roof. The recommended adhesive for installing polycarbonate snow guards is Surebond SB-190. This powerful glue is the industry standard for this type of attachment. Pad-style snow guards are typically unsuitable for curved roofs, as they require a flat surface for correct installation. In these situations, consulting with the roofing manufacturer for their specific recommendations regarding snow retention is advisable.

TBC Masterseam

The TBC Masterseam panel offers a high-quality standing seam roofing system. It uses a 1-1/2 inch mechanically locked seam, which you can configure as a single or double lock to increase protection against the elements. This roofing panel is available in various materials, including steel, aluminum, copper, and zinc. It comes coated with Kynar 500 or Hylar 5000 finishes to ensure resistance to fading and chalking. The Masterseam has panel widths of 12, 16, and 18 inches. The panels are manufactured with an AZ50 Galvalume substrate, providing strong resistance to corrosion, and they come in a wide selection of colors and finishes. Factory-made panels can reach lengths of up to 80 feet. At the same time, on-site fabrication allows for even longer panels, exceeding 150 feet when necessary. Install this system on roofs with a minimum slope of 1:12. However, the Bryer Company can offer solutions for projects with lower slopes. A 35-year finish warranty covers the TBC Masterseam panel and, when using seam sealant, can include a weather-tightness warranty of up to 30 years. It is tested and certified for wind uplift, fire resistance, impact resistance, water penetration, and air infiltration, making it a reliable choice for architectural and upscale residential roofing projects. Its versatility, durability, and many material and color options make it especially suitable for custom and high-end applications. See the Snow Guards Compatibility Chart for Bryer Company TBC Masterseam Standing Seam Metal Roofing Panels.

These panels are versatile, making them suitable for many snow retention systems, especially adhesive-mounted polycarbonate guards. Correct adhesive application is essential to keep moisture from building up between the snow guards and the panels. Our product range features larger models such as IceJax II, Snojax II, and SnoBlox Ace, as well as more compact versions like Deuce and IceJax I. For added safety and better snow and ice management, we recommend the SnowBreaker and SnowBreaker 3M. The unique ribbed design of the panels also accommodates clamp-on snow guards, including rail systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. While standard installations typically use stainless steel SnoBar clamps or aluminum RoofClamp options, it's wise to test a clamp sample in advance to ensure it matches your panel.

TBC-Truloc

The TBC-Truloc roof panel is a standing seam metal roofing solution for residential and light commercial buildings. It features a 1 1/2-inch snap seam that provides solid seam engagement and adequate protection against the elements. Customers can choose between 12 and 16-inch panel widths made from AZ50 Galvalume steel for enhanced resistance to corrosion. The panels are finished with high-quality Kynar 500 or Hylar 5000 paint, ensuring long-lasting color and durability. They are available in either 24 or 26-gauge steel. This roofing system features a separate, galvanized floating clip that allows the panels to expand and contract as temperatures fluctuate—a crucial feature for longer panels, which manufacturers can produce in lengths up to 50 feet. Bryer recommends the system for roofs with a minimum slope of 3:12. It can be factory-notched for a clean appearance at the eaves. Homeowners and builders also have a wide selection of colors to choose from. The TBC-Truloc panel has a limited lifetime warranty for residential installations, reflecting its long-term reliability. In terms of performance, this roofing panel has been tested for and meets several essential standards, including wind uplift, fire resistance, and impact resistance. Its design ensures it can withstand challenging weather conditions and provide dependable service for years. It is a strong option for those seeking a durable and visually appealing metal roof. See the Snow Guards Compatibility Chart for Bryer Company TBC-Truloc Standing Seam Metal Roofing Panels.

With their exceptional adaptability, these roofing panels work with a broad assortment of snow retention systems, particularly those that use adhesive-mounted polycarbonate parts. It is crucial to apply adhesive properly to prevent moisture from gathering between the snow guards and the panels. The product line includes larger models like IceJax II, Snojax II, and SnoBlox Ace, as well as smaller options such as Deuce and IceJax I. We recommend SnowBreaker and SnowBreaker 3M for increased safety and improved snow and ice management. The panels' unique rib design supports clamp-on snow guards, including rail systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. Although most installations rely on standard stainless steel SnoBar clamps or aluminum RoofClamp options, testing a clamp sample first is advisable to ensure it fits your specific panel style.

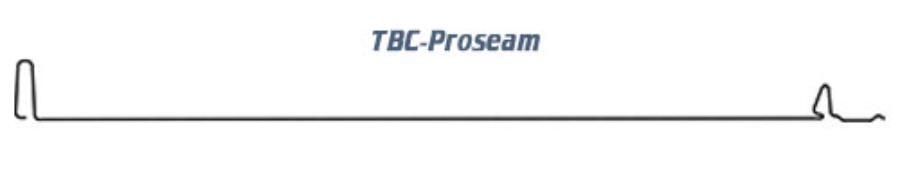

TBC-Proseam

The TBC-Proseam panel is a standing seam roofing system well-suited for commercial and residential uses. It is known for its strength, resistance to weather, and straightforward installation process. The panel features a snap seam profile that stands 1 inch high, contributing to its durability and ability to withstand harsh conditions. These ribs are available in 12 or 16-inch configurations. Made from high-quality AZ50 Galvalume steel, the panel is coated with a premium paint finish to protect against corrosion and sun damage. Its concealed clip fastening system allows the roof to expand and contract with temperature changes, helping to preserve its structure over time. Panels can be ordered in continuous lengths up to 60 feet, with even longer options available through on-site fabrication. Both 24-gauge and 26-gauge steel versions are available; the thicker 24-gauge is compatible with various fall protection systems, while the 26-gauge is best paired with strap-style anchors to maintain panel strength. The product comes with a limited lifetime warranty for residential projects, giving homeowners peace of mind about its longevity. Several industry organizations have tested and certified the TBC-Proseam panel to meet wind, fire, and impact resistance standards. It is a reliable and practical choice for various roofing needs. Its snap seam design and integrated fastening flange streamline the installation process, making it efficient and cost-effective for new builds or re-roofing projects requiring lasting protection and performance. See the Snow Guards Compatibility Chart for Bryer Company TBC-Proseam Standing Seam Metal Roofing Panels.

These roofing panels are incredibly versatile, making them an excellent fit for numerous snow retention systems, especially those using adhesive-mounted polycarbonate components. Accurate adhesive application prevents moisture accumulation between the snow guards and the panels. The product line features larger models such as IceJax II, Snojax II, and SnoBlox Ace, along with more compact options like Deuce and IceJax I. For enhanced safety and better snow and ice release management, consider the SnowBreaker and SnowBreaker 3M. The panels' distinctive rib design is also suitable for clamp-on snow guards, including rail systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. While most setups involve standard stainless steel SnoBar clamps or aluminum RoofClamp options, testing a sample clamp beforehand is a smart move to guarantee compatibility with your panel style.

The Bryer Company Compatibility Chart for Snow Guards

| TBC-Ultra Panel | TBC-Superseam Panel | TBC-Super Curve Panel | TBC-Caploc Panel | TBC Masterseam Panel | TBC-Truloc | |

|---|---|---|---|---|---|---|

| IceJax I Glue Down | YES | YES | NO | YES | YES | YES |

| IceJax II Glue Down | YES | YES | NO | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | NO | YES | YES | YES |

| SnoBlox Ace Glue Down | YES | YES | NO | YES | YES | YES |

| Snojax II Glue Down | YES | YES | NO | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | NO | YES | YES | YES |

| SnowBreaker 3M | YES | YES | NO | YES | YES | YES |

| SnoBar Standing Seam | YES | YES | YES | NO | YES | YES |

| ColorBar Standing Seam | YES | YES | YES | NO | YES | YES |

| SnoBar RCB-3 | YES | YES | YES | NO | YES | YES |

| ColorBar RCB-3 | YES | YES | YES | NO | YES | YES |

| SnoBar 2-Bar | YES | YES | YES | NO | YES | YES |

| ColorBar 2-Bar | YES | YES | YES | NO | YES | YES |

| SnoCleat RC | YES | YES | YES | NO | YES | YES |

| SnoCleat RCT | YES | YES | YES | NO | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by The Bryer Company

Assess Local Snow Loads

Before choosing a snow retention solution, research the typical snow accumulation in your area. Pad-style snow guards generally handle up to 45 pounds per square foot. Rail systems are engineered for locations with more substantial snowfall.

Verify Product Compatibility with Your Roof

Order product samples to confirm they fit your specific roof profile. This precaution helps ensure proper compatibility and reduces the likelihood of installation challenges.

Opt for Non-Penetrating Attachment Methods

To protect your roof's warranty and minimize the risk of leaks, select snow retention options that use clamps or adhesives rather than fasteners like screws or nails.

Incorporate Ice Control Accessories as Needed

Consider adding ice management components—such as our aluminum IceStoppers—to your bar or rail systems in regions where ice buildup is common. These additions help prevent ice from sliding underneath the rails, especially on roofs with taller seams.

Schedule Installation for Warmer Months

Plan installation during late spring or early summer for adhesive-based polycarbonate snow guards. Most adhesives require about a month of temperatures above 50°F to fully cure, though they become water-resistant within 24 hours.

Coordinate Snow Guard Placement for Load Distribution

Install snow guards to distribute the snow load evenly across your roof. For pad-style models, use a staggered arrangement; align rail systems in straight rows. Avoid grouping guards in isolated spots, which can create structural weak points. Refer to the manufacturer's spacing guidelines for optimal placement.

Match Snow Retention to Roof Aesthetics

Choose snow retention products that complement your roof's appearance. Options include metal snow guards in powder-coated finishes or with inserts to blend with your building's design.

Conclusion

SnoBlox-Snojax is committed to guiding customers through every step of their snow guard installation by providing personalized assistance and a range of educational materials. Our team is available on weekdays to answer installation questions via phone or email, offering advice tailored to each individual's situation. In addition to direct support, customers can use helpful tools such as the Snow Guard Buyer's Guide to make the selection process easier, while a dedicated web page shares best practices and points out common errors to avoid. SnoBlox-Snojax empowers customers to confidently approach their installations by focusing on clear information and high-quality products. This thorough approach reflects the company's dedication to outstanding customer service, excellence, and dependable snow management solutions.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.