Snow Retention Solutions for RLS Metal System’s Standing Seam Roofs

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jan 14th 2026

See the Snow Guards Compatibility Chart for RLS Metal Systems Standing Seam Metal Roofing Panels.

Which snow guard systems work best with RLS Metal Systems' standing seam panels?

Standing seam metal roofing offers a modern look and long-lasting performance. Still, it also brings specific safety challenges in climates with regular snowfall.

Effective snow management is essential to reduce winter-related risks. When snow and ice suddenly release in one large sheet, a situation commonly referred to as a roof avalanche, they can cause significant damage to anything below. Vehicles, landscaping, and outdoor equipment are all at risk, and a sudden slide can pose a danger to people and pets. To minimize these hazards, installers rely on snow guards and bar-style retention systems designed to match the roof panel's geometry and attachment method. Because concealed-fastener panels require solutions tailored to their specific profiles, choosing the right snow retention system is vital for long-term performance and safety. This blog highlights the snow guard options that pair best with RLS Metal Systems' standing seam panels, helping you select the right configuration with confidence.

About RLS Metal Systems

RLS Metal Systems is a regional manufacturer of engineered standing seam metal roofing systems, serving Upstate and Central New York, Western New England, and Northern Pennsylvania. Based in Middleburgh, NY, they produce high-quality, long-lasting roofing panels designed for residential, commercial, and industrial applications. As an authorized regional manufacturer of Drexel Metals products, RLS delivers roofing systems backed by extensive warranties and engineered performance. The company also sets itself apart through its contractor-focused approach, offering free in-depth installation training and ongoing support to ensure every affiliated installer is confident, efficient, and equipped to deliver exceptional results.

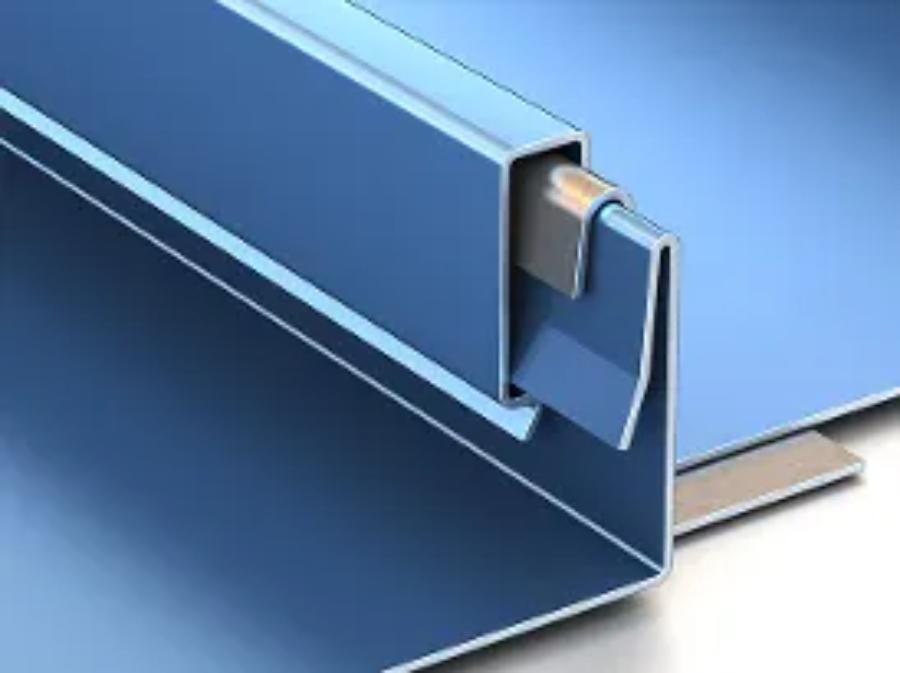

DMC 150SL

The DMC 150SL is a 1.5-inch snap-lock standing seam panel engineered for quick installation and crisp architectural appeal. Available in 12, 14, and 16-inch widths, it adapts easily to both residential and commercial applications. Material choices include 24 and 26-gauge Galvalume or Drexlume, as well as .032 aluminum. Its concealed clip fastening system allows for thermal expansion, making the 150SL a strong fit for projects that prioritize clean aesthetics and efficient installation. See the Snow Guards Compatibility Chart for RLS Metal Systems DMC 150SL Standing Seam Metal Roofing Panels.

A wide range of snow retention options is available thanks to the panel's seam shape and multiple width choices. The profile works especially well with adhesive-mounted polycarbonate snow guards, provided the adhesive is applied correctly to prevent moisture intrusion, a common cause of refreezing and guard failure. Larger guard models, such as IceJax II, Snojax II, and SnoBlox Ace, offer strong holding power. In comparison, smaller models, such as the SnoBlox Deuce and IceJax I, suit lighter snow loads. For controlled snow shedding, SnowBreaker and SnowBreaker 3M help slow and disperse sliding snow. The rib design also accommodates clamp-on systems, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, which can use standard SnoBar clamps or RoofClamp hardware. Softer metals, such as aluminum, may require additional rail rows to compensate for reduced panel rigidity.

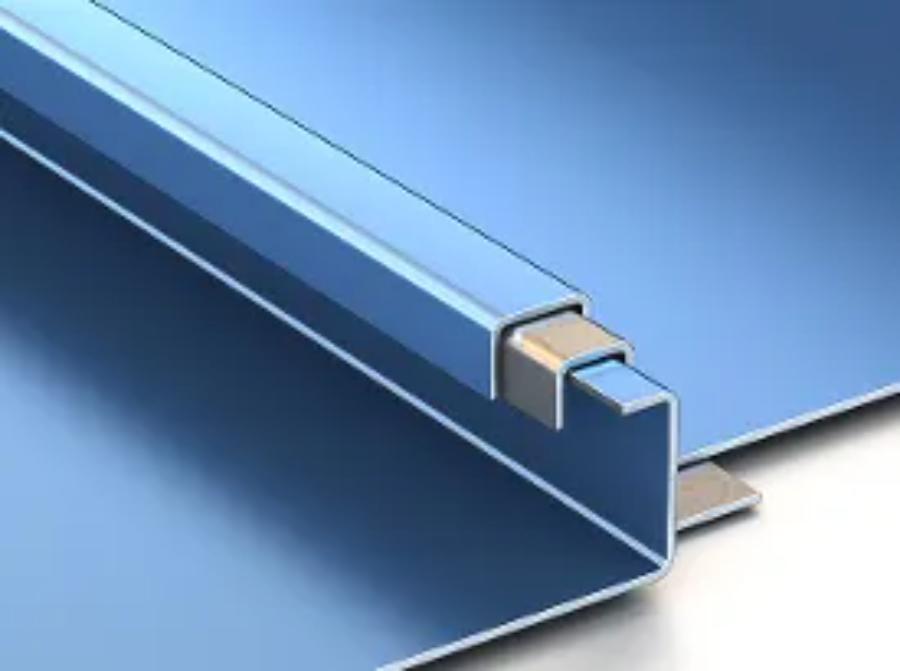

DMC 175S

The DMC 175S features a 1-3/4 inch seam height for exceptional structural performance. Its continuous interlocking design uses concealed clips and fasteners, allowing the panel to expand and contract without mechanical seaming. The snap-lock installation method is fast and reliable. It withstands very high design pressures. Available materials include Painted Galvalume (22, 24 ga), Drexlume (22, 24, 26 ga), and aluminum (.032, .040 in). Panels can be factory-produced or field-rolled to exact lengths. Rib options include flat, clip relief, striations, beads, small and large V-ribs, and pencil ribs. Widths range from 12 to 20 inches, with 14 and 18 inches being the most common. The minimum roof pitch requirement is 2:12. See the Snow Guards Compatibility Chart for RLS Metal Systems DMC 175S Standing Seam Metal Roofing Panels.

Because of its seam geometry and multiple width options, the 175S supports a broad selection of snow retention systems. Glue-down polycarbonate guards are a popular choice, but proper adhesive installation is essential to prevent moisture infiltration that could lead to refreezing or guard detachment. Larger snow guard models, IceJax II, Snojax II, and SnoBlox Ace, provide strong retention. At the same time, smaller options like the SnoBlox Deuce and the IceJax I work well in lighter conditions. SnowBreaker and SnowBreaker 3M help manage controlled snow release. The rib profile also accepts clamp-on systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, using either standard SnoBar clamps or RoofClamp attachments. Aluminum panels may use additional rail rows to offset the lower strength of the softer metal.

DMC 100SS

The DMC 100SS is a 1-inch mechanically seamed structural panel designed for residential and light commercial applications. The manufacturer engineered this system to offer durability, flexibility, and clean visual lines. It is available in widths from 13 to 21 inches, with 13, 17, and 21 inches recommended for optimal performance. Concealed fasteners and floating clips help reduce stress caused by temperature fluctuations, ensuring a smooth, consistent appearance. Designers can curve the panel to achieve greater architectural versatility. Installers can choose between Single Lock (90°) and Double Lock (180°) configurations. Material options include Painted Galvalume (22, 24, 26 ga), Drexlume (22, 24, 26 ga), aluminum (.032, .040 inch), copper, and zinc. Installers can mount the system over plywood or insulated metal decking with approved underlayments. They must maintain a minimum slope of 2:12. Rib choices include flat, clip relief, striations, beads, small and large V-ribs, and small and large pencil ribs. See the Snow Guards Compatibility Chart for RLS Metal Systems DMC 100SS Standing Seam Metal Roofing Panels.

Its snow retention compatibility is equally versatile. The panel's seam shape and width options make it suitable for adhesive-mounted polycarbonate guards, provided the adhesive is applied correctly to prevent moisture intrusion that could cause refreezing or failure. For full snow-holding capability, we recommend larger guards like IceJax II, Snojax II, and SnoBlox Ace. In comparison, smaller guards such as the SnoBlox Deuce and IceJax I work well for moderate conditions. SnowBreaker and SnowBreaker 3M help manage controlled snow shedding. The rib profile also supports clamp-on systems, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, using standard SnoBar clamps or RoofClamp hardware. Softer metals like aluminum or copper may require additional rail rows to compensate for reduced panel strength. Pad-style guards are generally not suitable for curved roofs because they need a flat mounting surface; in these cases, snow rail systems are the appropriate solution. If clamp-on rails won't work with the curved seam, consult the roofing manufacturer for approved snow-retention alternatives.

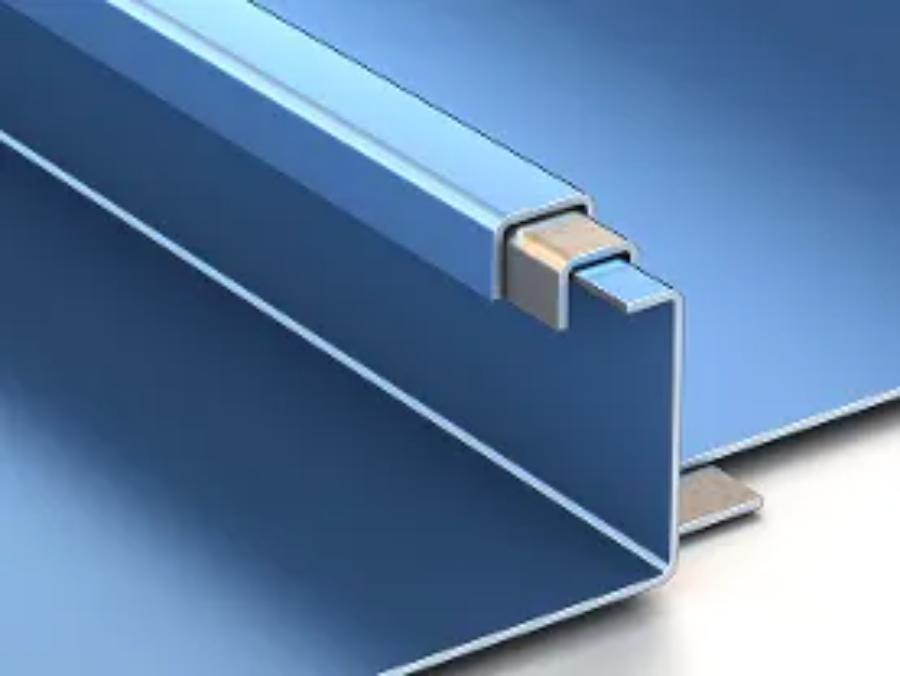

DMC 150SS

The DMC 150SS is a 1.5-inch mechanically seamed structural panel designed to complement a wide range of architectural styles. Concealed fasteners and floating clips help the system manage thermal expansion, keeping the roof surface smooth and uniform. Installers can curve the panel for barrel roofs, conical designs, and other architectural features. Installers can choose between Single Lock (90°) and Double Lock (180°) seams depending on project requirements. Material options include Painted Galvalume (22, 24, 26 ga), Drexlume (22, 24, 26 ga), aluminum (.032 and .040 inch), copper, and zinc. Installers can mount the system over plywood or insulated metal decking with approved underlayments. They must maintain a minimum slope of 2:12. Rib choices include flat, clip relief, striations, beads, and both small and large V and pencil-rib patterns. See the Snow Guards Compatibility Chart for RLS Metal Systems DMC 150SS Standing Seam Metal Roofing Panels.

Because of its seam geometry and range of widths, the 150SS supports a wide variety of snow retention systems. Adhesive-mounted polycarbonate guards are a strong match for this profile, provided the adhesive is applied correctly to prevent moisture intrusion that could cause refreezing or guard failure. Larger snow guard models, such as IceJax II, Snojax II, and SnoBlox Ace, offer maximum holding strength, while smaller options, such as the SnoBlox Deuce and IceJax I, work well for moderate snow loads. For controlled shedding, SnowBreaker and SnowBreaker 3M help break up sliding snow into smaller, safer pieces. "The rib design accommodates clamp-on systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, and installers can mount them using stainless SnoBar clamps or aluminum RoofClamp attachments. Softer metals, such as aluminum, may require additional rail rows to compensate for reduced panel strength. Pad-style guards are generally unsuitable for curved roofs because they need a perfectly flat mounting surface; in these cases, snow rail systems are the appropriate solution.

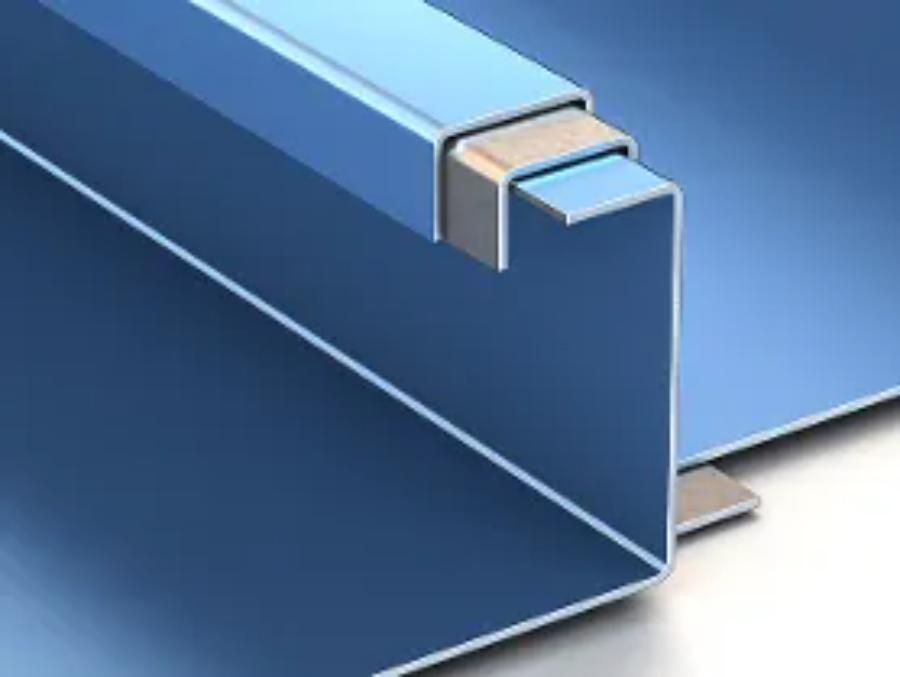

DMC 200S

The DMC 200S is a heavy-duty 2-inch mechanically seamed structural panel engineered for demanding commercial and industrial applications. Manufacturers design this panel to meet or exceed most wind-load and code requirements, ensuring reliable performance in high-demand roofing applications. The panel is available in widths from 12 inches to 20 inches, with 14 inches and 18 inches being the preferred options. Concealed fasteners and floating clips help manage thermal movement, ensuring the roof maintains a clean, consistent appearance. Installers can curve the system for large barrel roofs, small canopies, and other architectural features. Installers can select either Single Lock (90°) or Double Lock (180°) seams. Material choices include Painted Galvalume (22, 24, 26 gauge), Drexlume (22, 24, 26 gauge), aluminum (.032 and .040 inch), copper, and zinc. The 200S can be installed over plywood or insulated metal decking with approved underlayments and requires a minimum slope of 1.5:12. See the Snow Guards Compatibility Chart for RLS Metal Systems DMC 200S Standing Seam Metal Roofing Panels.

This panel supports a broad range of snow retention solutions thanks to its seam profile and multiple width options. Glue-down polycarbonate guards are a common choice, but proper adhesive installation is essential to prevent moisture intrusion that could lead to refreezing or guard detachment. Larger snow guard models, such as IceJax II, Snojax II, and SnoBlox Ace, offer strong snow-holding capability, while smaller guards like the SnoBlox Deuce and IceJax I work well for lighter conditions. SnowBreaker and SnowBreaker 3M help manage controlled snow release by breaking the snow-pack into smaller sections. The rib shape also works with clamp-on systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar, using stainless SnoBar clamps or aluminum RoofClamp attachments. When the roof uses softer metals like aluminum, installers may need to add extra rail rows to compensate for reduced panel strength. Pad-style guards are not recommended for curved roofs because they require a flat mounting surface; in these cases, snow rail systems are the proper solution.

RLS Metal Systems Compatibility Chart for Snow Guards

| DMC 150SL Panel | DMC 175S Panel | DMC 100SS Panel | DMC 150SS Panel | DMC 200S Panel | |

|---|---|---|---|---|---|

Ecojax |

YES | YES | YES | YES | YES |

IceJax I |

YES | YES | YES | YES | YES |

IceJax II |

YES | YES | YES | YES | YES |

SnoBlox Deuce |

YES | YES | YES | YES | YES |

Ace |

YES | YES | YES | YES | YES |

Snojax II |

YES | YES | YES | YES | YES |

SnowBreaker |

YES | YES | YES | YES | YES |

SnoBar |

YES | YES | YES | YES | YES |

ColorBar |

YES | YES | YES | YES | YES |

SnoBar RCB-3 |

YES | YES | YES | YES | YES |

ColorBar RCB-3 |

YES | YES | YES | YES | YES |

2 Bar SnoBar |

YES | YES | YES | YES | YES |

2 Bar ColorBar |

YES | YES | YES | YES | YES |

SnoCleat RC |

YES | YES | YES | YES | YES |

SnoCleat RCT |

YES | YES | YES | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by RLS Metal Systems

Verify that guards match your roof design.

Select snow guards engineered for your roof's specific panel profile and material. Using compatibility charts helps prevent improper pairings and supports long-term system reliability.

Apply adhesives during the correct weather window.

Installers should mount adhesive-applied guards only when temperatures stay above 50°F for a continuous 28-day period. Although the adhesive becomes water-resistant within the first day, it needs roughly four weeks to cure completely. Avoid using Surebond SB-190 on copper panels, as it can accelerate corrosion.

Order sample snow guards for test-fitting.

Samples can be ordered without minimum quantities, allowing installers to test-fit guards directly on the roof. This practice helps confirm proper alignment and sizing while reducing the likelihood of installation mistakes. Always follow the manufacturer's instructions to maintain warranty coverage.

Use systems tailored for unique roof shapes.

Roofs with sharp pitches, curved areas, or unusual geometries often require specialized snow-retention solutions. Consult your roofing supplier to determine which system is best suited for these nonstandard designs.

Account for local snow load standards.

Check local building codes to ensure your snow-retention system meets required load ratings. While pad-style guards typically support up to 45 pounds per square foot, regions with heavier snowfall may require stronger rail-style systems.

Adapt installation for complex roof features.

Snow guard placement may need to be adjusted to work around valleys, slope transitions, and other architectural elements. Proper positioning in these areas is essential to maintain system effectiveness and prevent performance issues.

Conclusion

Our team is here to assist you from the very first planning steps through the final installation of your snow guard system. Whether you contact us by phone, email, or through our website, you'll receive project-specific guidance designed to help you move forward with confidence. To make choosing the right products easier, we offer a comprehensive Snow Guard Buyer's Guide and a Best Practices manual filled with expert recommendations. These tools help you avoid common pitfalls and approach your installation with clarity and assurance. By combining straightforward instructions, dependable products, and attentive customer support, we work to ensure your snow retention system performs exactly as intended. Every interaction reflects our dedication to safety, integrity, and reliable service.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.