The History of Standing Seam Snow Guards

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Mar 15th 2024

Snow retention has been crucial for building maintenance and protection for centuries, particularly in regions prone to heavy snowfall. Throughout history, people have developed various methods to prevent snow from sliding off roofs and causing damage to property, people, and pets below. In this blog, we will delve into the fascinating journey of snow retention technology, tracing its origins from primitive solutions like rocks and logs to the innovative clamp-on systems of today, focusing on the contributions of SnoBar, a pioneering product in the industry.

Centuries Ago: The Origins of Snow Retention

Snow retention techniques trace back to ancient times, primarily in regions like Europe where heavy snowfall was common. Early inhabitants devised rudimentary methods using natural materials like rocks and logs placed strategically on roofs to hold snow in place and prevent it from sliding off. These early solutions were effective to some extent but lacked the sophistication and reliability of modern snow retention systems. People commonly set up rocks in staggered field formations over roofs to distribute weight and create friction on the roof to slow or stop roof avalanches. This primitive snow guard method eventually gave way to today's individual metal and polycarbonate pad-style snow guards. Logs were another standard method of snow retention at this time, with long, straight logs later developing into snow bars, snow fences, or snow rail-style snow retention systems.

The Rise of Metal Roofing and the Need for Innovation

Fast forward to the 20th century, and the advent of metal roofing, particularly standing seam metal roofs, revolutionized the construction industry. Metal roofs offer durability, longevity, and a sleek appearance, making them increasingly popular in snow-prone regions like Colorado. However, the smooth surface of metal roofs posed a significant challenge: snow accumulation could lead to sudden and dangerous avalanches, posing risks to property and individuals below. While customers enjoyed the clean, stylish look of this new roofing type, issues with snow retention continued to pose problems for these slippery roof panels. Their customers desperately needed a solution.

A Change in Direction Leads to Innovation.

In 1976, Dick Riddell founded Riddell & Company out of Englewood, Colorado, whose primary product offerings at the time were skylights and glulam beams. Eventually, Riddell & Co. partnered with AEP Span. This metal roofing company was revolutionizing the industry with its developments in standing seam metal roof panels that featured no visible, exposed fasteners. These panels, instead, utilized a series of concealed fasteners and clips that held the panels in place while allowing them to float freely and expand and contract with temperature changes. Many companies quickly followed suit with their own standing seam offerings, leading to a significant uptick in customer requests for snow retention solutions.

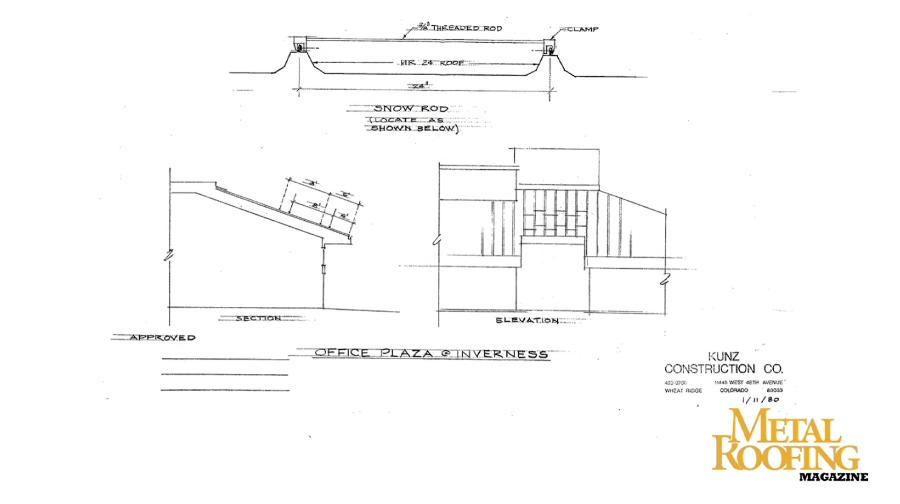

Amidst the growing demand for effective snow retention systems around 1980, Riddell & Co. began researching potential solutions for this problem, which led them to a company called Kunz Construction. Mr. Kunz, the owner of this company, was interviewed by Riddell & Co. about his recent invention utilized on an office plaza in Inverness, Colorado, just southeast of Denver. This project featured a Butler MR-24 trapezoidal standing seam roof with ribs on 24" spacing and an approximate rib height of just shy of 3". Using a system of beam clamps and custom bent threaded rods to follow the contours of the MR-24 panel, Mr. Kunz created a basic non-penetrating snow rail retention system. Because of its non-penetrating nature, the water integrity of the standing seam panels remained intact. This crude system marked the beginning of an eventual change in the roofing and snow retention industries.

Friends in the Industry

Since the mid-1970s, Riddell & Co. had worked closely with a polycarbonate snow guard company based out of Pennsylvania called Snojax, Inc. This company changed the snow guard game almost overnight with the invention of clear polycarbonate snow guards in 1976 as an answer to cheap metal snow guards prone to corrosion and staining of metal roof panels. From 1976 to 1984, the Snojax I snow guard dominated the industry as a screw-down snow guard for R-Panel and PBR-style roof panels. In 1984, however, with the standing seam metal roofing market showing no signs of slowing or stopping, SnoBlox-Snojax saw a need for a non-penetrating pad-style solution. Enter the Snojax II, the world's first clear polycarbonate glue-down snow guard for standing seam roofs. We recognized that using this form of attachment would minimize roof leaks, seam impairments, panel damage, warranty violations, maintenance concerns, and callbacks that come with putting snow guards on this type of roof. Surebond SB-190 adhesive was the glue used to install these guards back then, and it still remains in use to this day.

In the early days, Riddell & Co. experimented with various materials and techniques, collaborating with partners like Snojax to explore polycarbonate solutions glued onto roofs. While these early attempts showed promise, some customers preferred an even more robust system, reminiscent of the traditional log method used in Europe centuries ago.

The Birth of the SnoBar Clamp: A Revolution in Snow Retention Technology

In 1987, while working at the Chipeta Elementary School in Colorado Springs, Riddell & Co. was tasked with adding snow guards to the standing seam roofing over the doorways of the school. The installer, at the time, ended up fashioning a rail system by welding 2 bar joist clamps together and screwing the bar system directly to those clamps. Even though the steel clamps of this system utilized corrosion-prone pot metal, which later rusted, the system remained intact without damaging the roof. Despite the corrosion to the clamp itself, these clamps had zero negative impact on the roof or its painted surface.

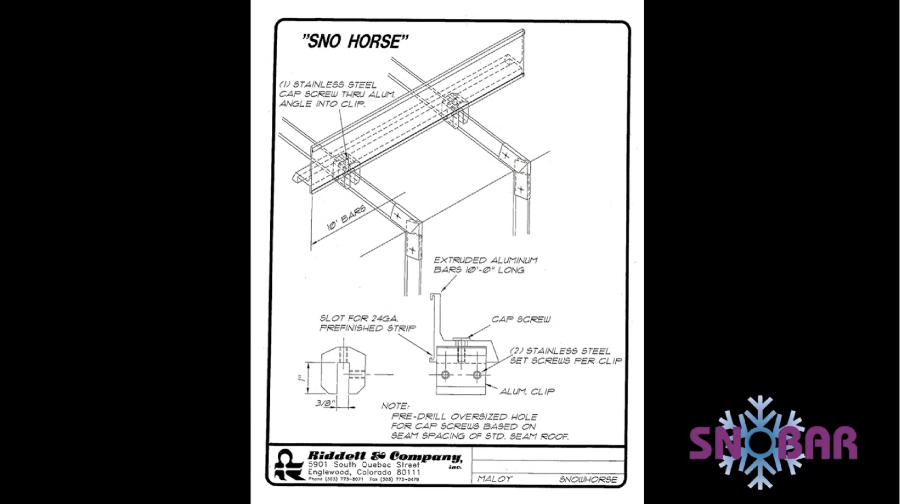

The real turning point came in 1990 when Jim Huff, a Riddell & Co. customer, and innovator in snow retention, devised a groundbreaking clamp and snow rail system inspired by a simple observation of a nameplate on his desk. Drawing inspiration from this everyday object, Huff developed the Sno Horse product, which featured a bar with a slide-in face to insert a piece of the metal panel. The ability of the Sno Horse to accept a slide-in color strip provided customers with a way to color-match their snow rails to their roofs without the extensive lead times often associated with painting.

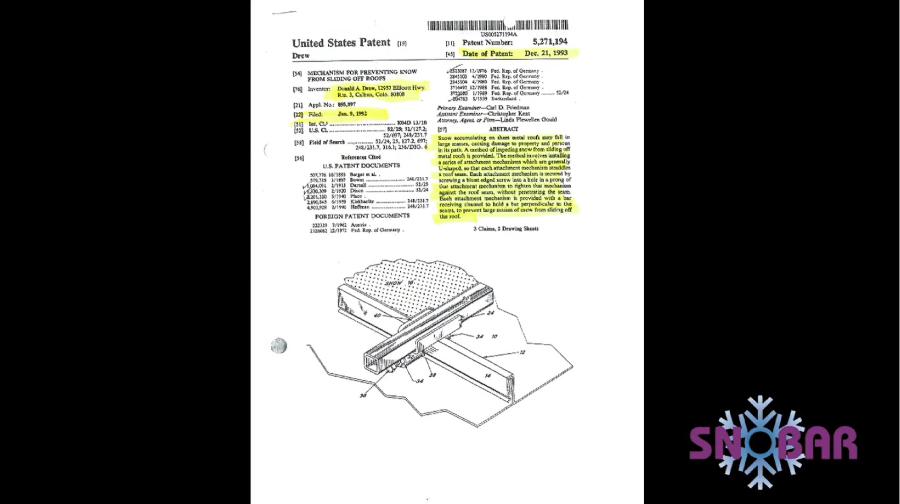

Around the same time, Donald Drew of Colorado Springs was also working on snow retention solutions. Drew's innovation culminated in developing the SnoBar standing seam roof clamp, which leveraged beam clamping technology and integrated it into a single-piece system. The SnoBar Clamp marked a significant milestone in the evolution of snow retention technology, offering enhanced compatibility with various roof seam types and improved resistance to rust through the use of stainless steel components. In June 1992, Don Drew filed for a patent for his SnoBar clamp.

Later, in 1992, Mr. Huff installed the Sno Horse snow retention system on a high-profile project for the Denver International Airport in collaboration with Riddell & Co. The world was introduced to Sno Horse at MetalCon 1993 in Dallas, Texas. It didn't take long for other manufacturers who were in attendance to get their eyes on this product and start the development of similar products of their own. Although Sno Horse found success at the show, even being featured by AEP Span in their booth, there was still plenty of room for improvement. Sno Horse suffered from two significant flaws. First, it required pre-drilling of each bar for a custom fit. Second, because of the roof clamp's small channel, the Sno Horse was limited to fitting only a few standing seam profiles that were available then.

Partnership and Progress: Action Manufacturing and the SnoBar Legacy

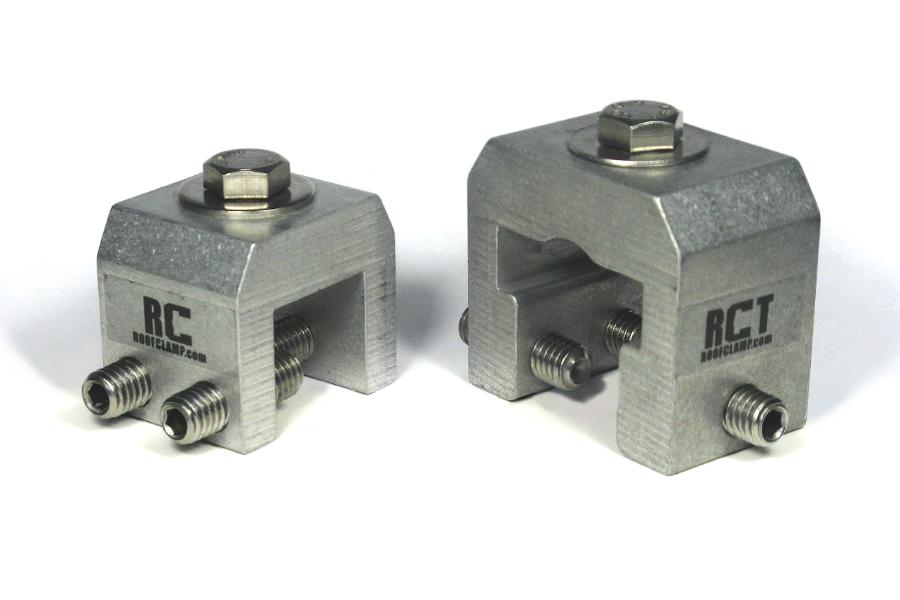

Recognizing the potential of the SnoBar clamp, Riddell & Company partnered with Don Drew to form Action Manufacturing in 1995. This strategic collaboration allowed for the refinement and widespread adoption of the SnoBar clamp, cementing its status as the industry's leading standing seam snow retention solution. Mr. Drew's SnoBar clamp fit many of the seams on the market and allowed for not only the top loading of the bar into the clamp but also the top loading of the clamp onto the seam. This clamp eliminated the need for seam feeding, which could mar and scratch the roof's seams, causing damage. The new partnership enabled painting and later powder coating the new Sno Horse system for customers seeking a full coverage color match. Unfortunately, the original SnoBar Clamps, made from mild steel, were prone to rusting and flaking of painted finishes. This corrosion led to the decision to produce all clamps and bars in stainless steel to avoid this issue with future projects. This change occurred in the late 90's. The company introduced galvanized steel bars to the product lineup in the early 2000s as a substantial cost savings for their customers. With its 50% additional coating, the gator-shield coating on this bar allowed for painting and powder-coating without the fear of corrosion and failure from the earlier bar systems. In 2004, SnoBlox-Snojax further solidified our relationship with Action Manufacturing and quickly became their largest SnoBar distributor.

This partnership also facilitated the development of innovations, such as the ColorBar system introduced in 2006. While customers enjoyed the look of fully painted or powder-coated systems, sometimes, lead times for these finishes were not acceptable to customers experiencing time crunches. Now was the perfect time to re-introduce the redesigned Sno Horse as the new ColorBar system. This revolutionary product allowed for the same integration of color strips into the aluminum snow retention bars, offering customers both functional and aesthetic benefits. From the original Sno Horse product, ColorBar improved upon the history of this design while still honoring the slide-in color strip known and loved by customers.

Tidying Up Loose Ends and Moving Into the Future: RoofClamp Is Born.

In 2010, Action Manufacturing continued pushing innovation boundaries by introducing the RoofClamp RCT. A design improvement to fit T-Seam and Bulb Seam roofs, this latest addition to the SnoBar lineup expanded the company's ability to provide comprehensive snow retention solutions for many roofing configurations. The standard SnoBar Clamp was incompatible with Bulb and T-Seam panels, leaving a gap in the market. This new aluminum Clamp utilized three cupped point stainless steel set screws, the same set screws used in the SnoBar Clamp. Unlike some competitors who touted bullet point or round nose set screws, Action Manufacturing chose to use cupped point screws that require less than half of the torque necessary to achieve a strong attachment point with round tip screws. You can view our blog about the Truth About Set Screws on our website.

Moving Into the Future: The Action Manufacturing and SnoBlox-Snojax Merger

In 2016, SnoBlox-Snojax purchased the assets of Action Manufacturing LLC in Colorado. Today, we are proud to offer our customers the SnoBar, ColorBar, RoofClamp, and WindBar of the same excellent quality as before and with enhanced customer service. You can still equip the ColorBar with the traditional slide-in color strips, and our customers can powder-coat all three systems to match their projects, regardless of size or scope. SnoBlox-Snojax continues to lead snow guard innovation with our new SnoCleat RC and RCT products, which utilize components from the ColorBar system to form individual seam-mounted snow guards.

Conclusion

The evolution of snow retention technology for standing seam roofs, from humble beginnings with rocks and logs to the sophisticated clamp systems of today, has characterized innovation, collaboration, and a relentless commitment to quality and reliability. These factors are pivotal in driving this progress and revolutionizing the way we approach snow retention in modern construction.

As we look to the future, the journey of snow retention technology continues, fueled by a passion for excellence and a dedication to meeting customers' evolving needs worldwide. With each innovation and advancement, we move closer to safer, more resilient buildings that can withstand the challenges of nature and winter weather. For inquiries or orders, contact us at support@snojax.com or 1-800-766-5291. Before purchasing, check out our Snow Guard Buyer's Guide and What Works and What Doesn't page for helpful insights. We're here to help!