How Do You Install Snow Guards on A Metal Roof?

Posted by Derek Gamble - SnoBlox-Snojax Specialist on May 12th 2025

Snow guards, also known as snow brakes, snow shields, or snow stops, are devices installed on rooftops to prevent snow and ice from sliding off in large, dangerous sheets, also known as “roof avalanches”. This is especially crucial for metal roofs due to their smooth surfaces which allow for easier snow and ice shedding than an asphalt roof, for example. Snow guards, when installed correctly, aid in protecting property, people, and pets on the ground below. These devices, strategically placed along the entire roofline and often in multiple rows going up the slope, can effectively hold winter precipitation in place, allowing it to melt gradually and shed safely in small manageable amounts. Installing snow guards on your roof involves so much more than just laying down some glue or running some screws into your roof. In this blog, we'll explore the process of planning for and installing snow guards on metal roofs, ensuring a secure and efficient process from start to finish. We must first determine the type of metal roof panel for installing the snow guards.

How Do You Tell What Kind of Metal Roof You Have?

There are three main types of metal roofs, standing seam, exposed fastener and concealed fastener nailstrip panels, each with different benefits.

The standing seam concealed fastener panel features sleek, vertical panels with hidden fasteners for a modern look and enhanced durability. The exposed fastener screw-down roofing is cost-effective and uses visible screws, providing a practical yet slightly less refined aesthetic. Finally, the NailStrip Standing Seam system offers easy installation, combining the advantages of standing seam roofing with a unique fastening method for a reliable and attractive option.

The Three Basic Types of Metal Roof Panels Explained

Standing Seam Panels (Floating Panels with No Visible Fasteners)

Standing seam, or hidden fastener, metal roofing has interlocking panels that have raised seams, effectively concealing the fasteners or clips beneath the surface. These panels rest above the roof structure without fasteners penetrating the panels themselves. Instead, multiple hidden metal clips are attached to the roof decking and support the panels, which are then secured to the clips using a male/female interlocking system and specialized seaming tools. This construction delivers a sleek, modern look. It improves weather resistance by preventing fastener penetrations that could lead to leaks and structural damage over time. There are a variety of seam shapes, widths, and heights to suit different preferences. Polycarbonate pad-style snow guards can be installed only with adhesive on these panels. Penetrations of standing seam panels can lead to roof damage, leaks, and a loss of the Manufacturer's warranty. You shouldn't install metal pad-style guards with adhesive. If you are looking for a stronger, more heavy-duty solution for your roof, clamp-on snow rails, and our clamp-on SnoCleat products are excellent options for your project. It is important to inform your contractor if you plan to add clamp-on snow guards or snow rails, as some panel shapes and wider seams may not be compatible with these products. Discussing snow retention needs early helps ensure any options remain available.

Screw-Down Panels (Exposed Screw Heads Fastening The Panels)

Exposed fastener metal roofs, also known as screw-down or corrugated roofs, are installed by securing panels directly through the metal surface into the underlying roof structure using visible screws or nails. These roofs expose the fastener heads, unlike concealed systems that hide their fasteners. Typically made from steel or aluminum, the panels often have ribbed or corrugated designs, such as R-panel or 5V crimped styles, adding strength and visual interest. This type of roofing is generally more affordable than standing seam options because the panels cover more area, use thinner metal, and require less labor and material during installation. However, the exposed fasteners are susceptible to damage from sunlight and temperature changes, which can eventually loosen them and compromise the roof's waterproofing. As a result, proper underlayment is crucial, and ongoing maintenance is needed to prevent leaks from displaced fasteners or worn gaskets. While exposed fastener roofs are a practical and economical choice for structures like barns, garages, or other non-heated buildings, they require regular upkeep. They are best suited for projects where upfront cost is a primary concern. These panels are compatible with a wide range of snow guard options. Screw-down pad-style snow guards made from metal and polycarbonate are compatible in most cases. In contrast, adhesive mounting of polycarbonate snow guards is a great option for those not wanting to put additional holes in the panels. Installers should not mount metal pad-style guards with adhesive. Screw down snow rail systems car able to be mechanically fastened to create a strong hold.

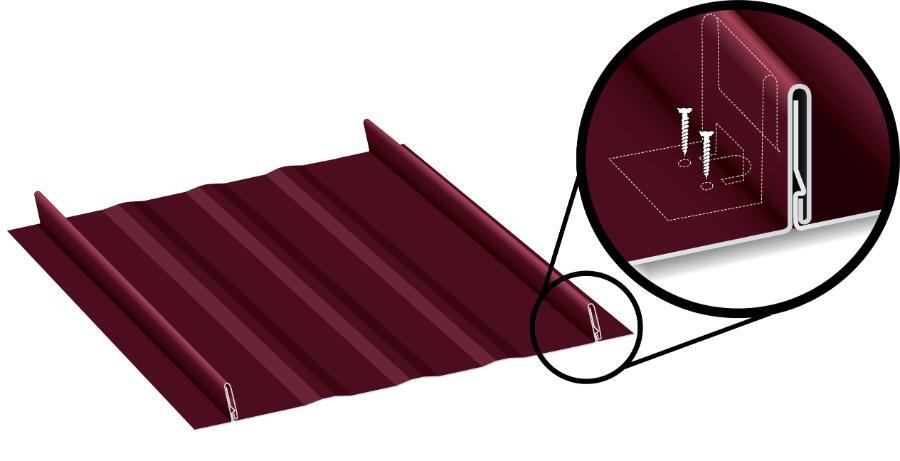

Nail Strip Panels (Screw Down Standing Seam Panels With No Exposed Fasteners)

Nailstrip panels offer a roofing option that blends features of both standing seam and exposed fastener systems. Although they belong to the standing seam category in terms of appearance, their installation method is more similar to that of exposed fastener roofs. Instead of clips like traditional standing seam panels, Nailstrip panels have a flange along the edge, often called a fastener or nail flange, which contains holes or channels for attaching the panels. Once fastened, the panels snap together, concealing the fasteners and maintaining a clean, seamless look. This style has become increasingly popular among contractors and DIY enthusiasts because it delivers the attractive look of a standing seam roof while being much easier to install, requiring no specialized tools or advanced skills. Many consider Nailstrip panels an ideal compromise, combining the best aspects of both roofing styles. Although this panel is not a true standing seam panel in every sense of the word, the same rules apply. You should use adhesive only for polycarbonate guards. Do not penetrate the panels with nails or screws. Use clamp-on snow guards or rails for heavy-duty protection.

For more information on this topic, please visit our blog, "What's the Difference Between Standing Seam and Exposed Fastener Metal Roofing?" This article thoroughly examines the different panel styles and options available on the market today.

Identify Your Roof Panel and Structural Substrate

There are differences in the guidelines for installing snow guards between the various panel types. Screw-down PBR and Ag Panels have different requirements than standing seam panels due to the difference in their installation techniques. Next, determine whether your panels are supported by decking, furring strips, or purlins. This will determine the best way to secure the snow guards. It is also important to note whether the structure underneath the panels is wood or metal. This has a major impact on recommended layouts and individual holding strength. Once you have figured this out, it is time to select your snow guards.

What Type of Snow Guards are Right For My Roof?

Different types of snow guards are available, each offering unique advantages suited to specific roof types and snow conditions.

Pad-Style Snow Guards

These are perhaps the most common option, typically consisting of individual plastic or metal snow guards that mount directly to the flat of the panel on their “pads” or “bases” using either screws and sealant or glue. These guards are versatile and suitable for various roofing types. Proper layout techniques typically require installation in staggered rows for additional weight distribution.

Polycarbonate Pad-Style Snow Guards

Clear polycarbonate snow guards, like the SnoBlox Ace, IceJax II, and SnoBlox Deuce, are installed individually either using an adhesive like our recommended SureBond SB-190 or with a combination of mechanical fasteners and liquid sealant like our recommended NovaFlex MR150. Either attachment method is compatible with most screw-down roofing panels as long as there is a wide enough flat surface for the guard to fit. When installing snow guards on a standing seam metal roof, it is never recommended to use screws due to the floating nature of this roofing style. Penetration of a standing seam panel can cause damage to the roof, can result in roof leaks, and can void your manufacturer’s warranty. Adhesive is the only correct method for attaching a pad-style snow guard to a standing seam roof. The transparent design and affordable price of polycarbonate pad-style snow guards—which are frequently offered in clear but can also be available in color-molded versions—make them popular with today’s customers. For on-site color comparisons, test samples should be acquired by ordering a few from the website. Installing these guards is simple for homeowners and most general contractors alike. This type of snow guard is not recommended for use in geographic locations with a ground snow load of 45 PSF or higher.

Metal Pad-Style Snow Guards

Unlike their polycarbonate peers, metal pad-style snow guards like our Stainless Steel SnowCatchers and SnoCleat PBR cannot be installed with adhesive. They require mechanical fasteners like our 2” long Master Gripper screws for wood structures or our 1.5” Master Driller screws for metal structures. Mechanical fasteners should not be used on standing seam metal roofs to avoid damage and warranty issues, thus making this style of snow guard incompatible with standing seam roofs. Like plastic snow guards, metal pad-style snow guards are also typically installed in a staggered formation and are not recommended for use in geographic locations with a ground snow load of 45 PSF or higher.

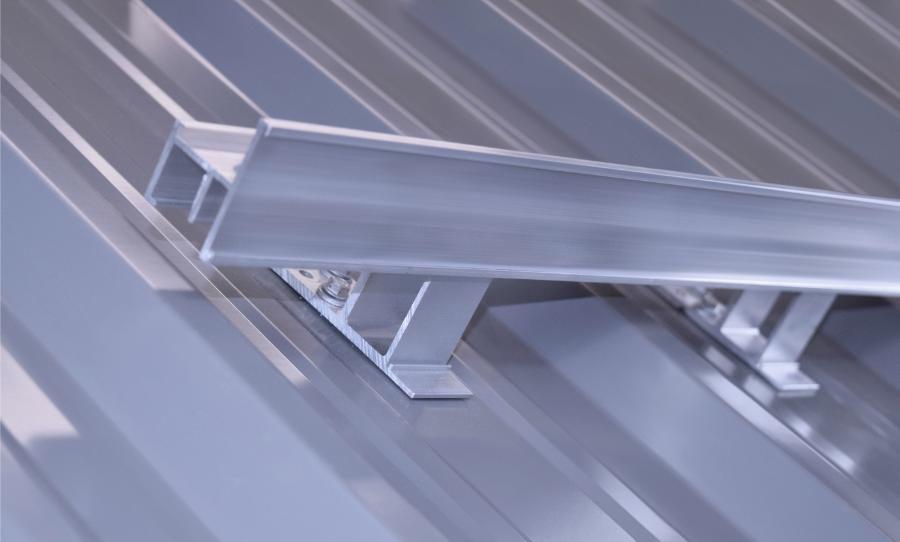

Individual Seam Mounted Snow Guards

For standing seam metal roofs, individual metal clamp-on snow guards such as the SnoCleat are often selected by customers. This type of metal snow guard attaches directly over the panel’s seams using non-penetrating clamps and set screws. We've cleverly combined the advantages of our innovative RoofClamps and reliable ColorBar snow rails to create our popular SnoCleat RC and RCT for just this purpose. Combining these components has produced a product that, despite being fresh to the market, has already begun attracting a devoted following. Because most of the snowpack is held in the flat of the panel, individual seam-mounted guards are often exposed to uneven loading which can cause big problems. In contrast to numerous other seam-mounted guards available on the market, our products have a swivel base for the guard's face, which permits movement if it is used incorrectly or faces impacts from sliding snow and ice. Without this feature, other one-piece snow guards frequently sustain damage from bending or twisting, which can damage the guard and the panels, or cause the panels to disengage from one another. This often ends with hefty repair bills. It is recommended that these guards be installed in staggered rows much like pad-style guards to help with equal distribution of weight. This type of snow guard also is not recommended for use in geographic locations with a ground snow load of 45 PSF or higher.

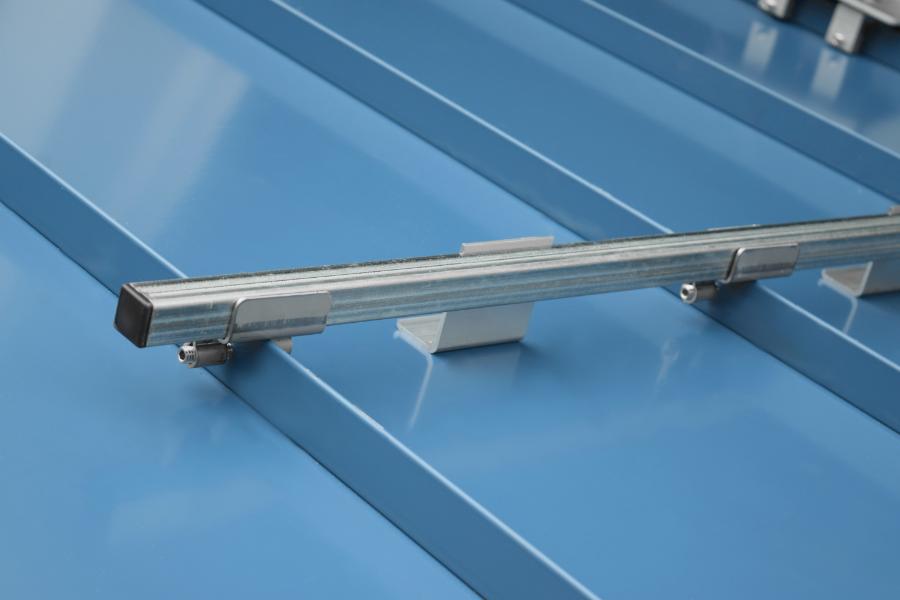

Snow Rail Systems

In regions with ground snow loads of 45 psf or higher, buildings require stronger snow retention solutions beyond pad-style or individual clamp-on guards. Snow bars or snow rail systems like our galvanized / stainless steel SnoBar and our aluminum ColorBar systems are necessary in these cases. These heavy-duty systems consist of continuous rails installed parallel to the eave that run the entire length of the roof and often require multiple rows going up the slope on larger roof faces. Unlike individual clamp-on models, which utilize small sections of bar, snow rail systems offer long continuous bars, typically between 6’-12’, for added strength, ideal for steep roofs and heavy snow loads. Effective rail shapes typically feature a flat face that is perpendicular to the panel, creating a robust barrier to hold snow and ice. Diamond or rounded bars are often less effective, acting as ramps or cutting blades rather than barriers. Snow rail systems offer both unmatched strength and clean aesthetics. Mounting options are not limited to standing seam roofing either. We also have attachment methods for PBR, R-Panel, 2.67 Wavy Corrugated, Shingle, and Membrane roofs as well. While the standard silver mill finish is quite attractive, these systems can also be customized with powder coating or color strips to match the roof, providing our customers with options to add to their roof's appearance instead of detracting from its beauty.

Choosing The Right Snow Guards for Your Metal Roof

Before installing snow guards, thorough preparation and planning are essential to ensure a successful outcome. Begin by assessing the roof's condition and identifying areas prone to snow buildup. Additionally, determine the expected snow load based on regional climate data and building codes. Once you have a clear understanding of the roof's requirements, calculate the spacing and layout for the snow guards. This calculation considers factors such as roof pitch, snow load, and the type of snow guards selected, ensuring optimal performance and coverage. Follow manufacturer-provided spacing guidelines for optimal snow retention placement. A proper layout will span the entire length of the roof and frequently includes multiple rows going up the slope. Snow retention must also be installed on all upper roof areas that may shed onto lower areas where protection is desired. Otherwise, these locations have a high risk of becoming overloaded. You can visit our Spacing Guidelines Page for more information.

It is never recommended to install snow guards, regardless of the type selected, in only isolated areas like just above doorways, chimneys, vent pipes, HVAC units, garage doors, etc. Installation in this way is prone to dramatic failure due to overloading and can easily result in damage to the roof panels, structure, snow guards, and damage to what you were trying to protect below in the first place.

The Snow Guard Installation Process

Installing snow guards on a metal roof requires attention to detail and adherence to best practices. Begin by gathering the necessary tools and materials, including the snow guards and any adhesives, fasteners, or sealant that will be needed. Next, mark the layout according to your spacing calculations, ensuring uniform placement along the roofline.

If the metal roof panels are attached only to purlins or firing strips and the mechanical attachment method is being employed, the snow guards need to be fastened into these structural elements. If plywood decking is present, make sure there is enough to hold the snow guards in place. In situations where there isn't enough structural support to screw into, internal blocking may need to be installed. Adhesive or clamps should be used to place individual snow guards on standing seam metal roofs. Perforating the panels of a standing seam roof is, once again, not advised. On our website, we provide comprehensive color instructions for quick and easy access. You will receive printed versions of these instructions, as well, In the box with your order.

Typically, you will place your first row about one foot above the lower edge of the roof. This initial row will need to be positioned above the external structural wall if there is an unsupported overhang on the project. To ensure equal weight distribution, more rows may be needed to proceed up the slope. You can find helpful spacing suggestions on our spacing guidelines page.

It's important to note that these are only general steps and that installation instructions related to a given snow guard type and manufacturer's instructions may differ. To guarantee correct installation, always refer to the manufacturer's particular instructions for the snow retention system being used.

Snow Guard Maintenance and Safety Considerations

Once installed, regular maintenance of snow guards is essential to ensure continued effectiveness and safety. Perform routine inspections, at least annually, to check for any damage or signs of wear, particularly after severe weather events. When it comes to snow removal on a roof, exercise caution to avoid damaging the snow guards or compromising their performance. Use gentle techniques such as brushing or raking to remove snow buildup, avoiding harsh tools or excessive force.

Throughout the installation and maintenance process, always prioritize safety. Utilize appropriate personal protective equipment, such as harnesses and non-slip footwear, and take precautions to prevent falls or injuries. The RidgePro is an excellent tool for use when installing snow guards or doing roof snow retention inspections.

Conclusion

In conclusion, installing snow guards on a metal roof is critical in safeguarding property and occupants from the risks associated with roof snow slides. By selecting the right type of snow guards, thoroughly planning the installation process, and prioritizing maintenance and safety, property owners can enjoy peace of mind knowing their roofs are well-equipped to handle winter weather conditions. For snow guard installation resources, visit our "Snow Retention Installation Instructions" page. You will find detailed guides, full-color instructions, and informational videos to aid installation.

For more information, or to place an order, drop us an email at support@snojax.com, or simply give us a call at 1-800-766-5291. We're here to help! Also, make sure to give our Snow Guard Buyer’s Guide and our What’s Works and What Doesn’t page a quick read, as it contains lots of important and easily digestible information to consider before placing your order.