Snow Guards For Miller Steel Buildings Standing Seam Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Feb 5th 2025

See the Snow Guards Compatibility Chart for Miller Steel Buildings Standing Seam Metal Roofing Panels.

Are Snow Guards Recommended for Miller Steel Buildings Concealed Fastener Metal Roofs?

The winter season presents significant challenges for buildings with standing seam metal roofs, particularly the risk of unexpected snow and ice slides.

These sudden avalanches seriously threaten people, pets, vehicles, and property near the building. The smooth surface of these roofs exacerbates the problem by allowing winter precipitation to accumulate and then release without warning. This safety concern highlights the importance of implementing effective snow and ice retention strategies to protect the surrounding area. We have developed various snow retention devices, including snow guards and rail systems that adapt to roof styles. To address this issue, When implementing these protective measures, it is essential to consider several factors, such as the roof's pitch, panel configuration, and local climate conditions. Property owners can use online resources, including articles and blog posts, to help them select appropriate snow retention solutions for their specific needs. By utilizing these resources and adopting innovative approaches, building owners can significantly reduce the risks associated with snow and ice accumulation on standing seam metal roofs. This proactive approach creates a safer environment during winter, safeguarding people and property from potential harm.

Standing Seam Metal Roof Panels by Miller Steel Buildings

Miller Steel Buildings has established itself as a leading provider of pre-engineered metal building solutions over the past 30 years. Based in Flourtown, Pennsylvania, the company offers a comprehensive range of services, including designing, supplying, and installing steel structures for diverse applications. Their expertise covers industrial facilities, self-storage units, religious buildings, offices, retail spaces, and recreational structures catering to domestic and international markets. The company's success stems from its dedicated team of sales professionals, engineers, and plant personnel who collaborate closely with clients to create cost-effective and structurally sound buildings. Miller Steel Buildings' custom-engineered designs, ranging from straight columns to gable systems, prioritize functionality and efficiency without compromising on competitive pricing. Their support extends from the initial quotation to the final stages of building erection, ensuring a smooth process for clients. Miller's versatility is evident in its ability to deliver clear-span storage, metal garages, and specialized structures like riding arenas and sports facilities. For those who prefer a more hands-on approach, the company also offers do-it-yourself steel building kits with detailed assembly manuals. This comprehensive range of services and products cements Miller Steel Buildings' position as a trusted name in the pre-engineered metal building industry.

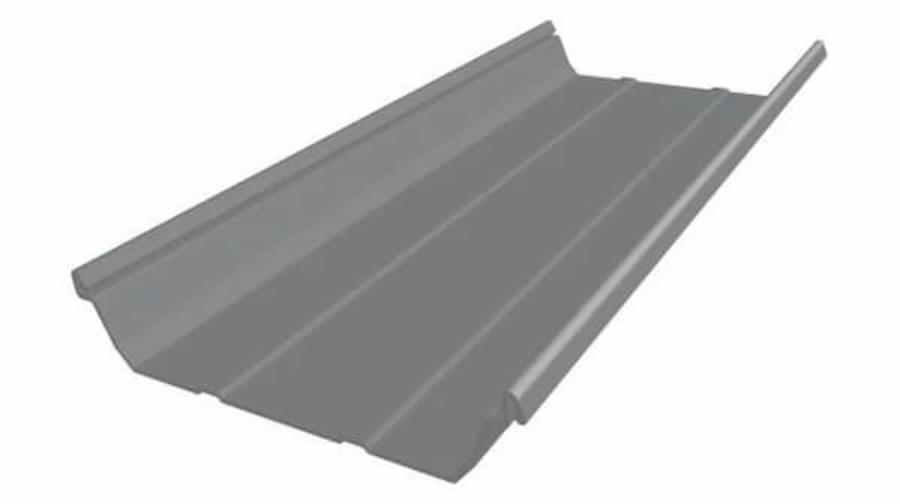

Ultra-Dek Panels

Ultra-Dek panels represent a cutting-edge roofing solution for various industrial and architectural applications. The trapezoidal leg standing seam panels feature a three-inch rib height, which provides robust structural integrity and aesthetic appeal. This panel comes in 12, 18, and 24-inch widths. The versatility of Ultra-Dek is evident in its variety of coverage widths and steel substrate options, allowing for customization to suit diverse building designs and structural requirements. High-quality finishes enhance the panels' durability, providing unique benefits for longevity and visual appeal. This adaptability extends to the concealed fastening system, which accommodates thermal fluctuations through various clip options, making Ultra-Dek suitable for different environmental conditions and insulation needs. The thoughtful design also prioritizes water resistance, with seam placement strategically configured to minimize leakage risks, particularly in vulnerable areas. Ultra-Dek's suitability for low-slope roofs, impressive water-tightness, and structural reliability make it an excellent choice for many roofing projects. The availability of standard and custom panel lengths and options for smooth or embossed finishes further underscores the system's flexibility. Ultra-Dek panels offer a comprehensive roofing solution that balances performance, aesthetics, and adaptability, whether for new construction or retrofitting. See the Snow Guards Compatibility Chart for Miller Steel Buildings Ultra-Dek Standing Seam Metal Roofing Panels.

The innovative design of this roof panel accommodates a wide array of our snow retention solutions, with a particular emphasis on our adhesive-mounted polycarbonate snow guards. It's essential to correctly apply the adhesive to prevent issues such as detachment from moisture infiltration and subsequent re-freezing. Our product range encompasses both larger and smaller options to suit various needs. We offer models like IceJax II, Snojax II, and SnoBlox Ace for those requiring more substantial protection. Compact versions such as SnoBlox Deuce and IceJax I are available for less demanding applications. We've developed the SnowBreaker and SnowBreaker 3M variants to enhance further control over sliding snow and ice. The panel's ribbed construction is compatible with multiple clamp-on snow guard options, including our SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar rail systems. These can be securely attached using stainless steel SnoBar clamps or aluminum RoofClamp alternatives. We strongly advise testing a clamp sample before finalizing your order to ensure the perfect fit for your application.

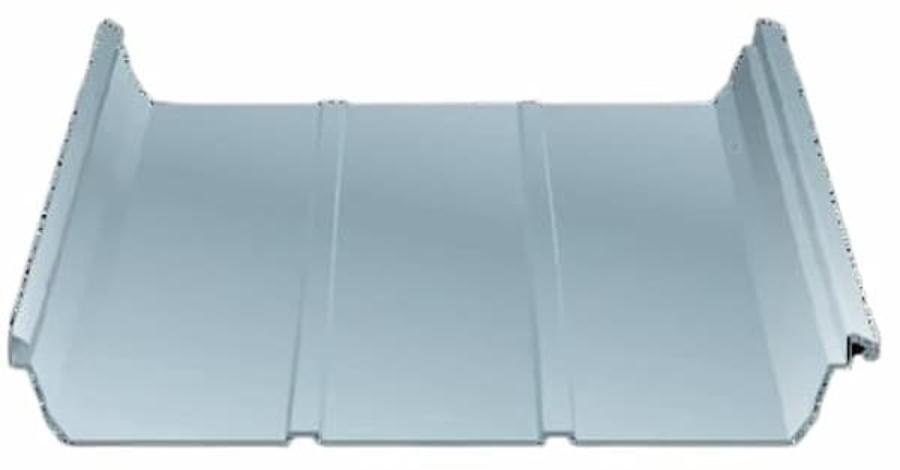

Double-Lok Panels

Double-Lok panels are engineered for exceptional longevity and functionality, making them a top choice for various applications, including industrial, architectural, and retrofit projects. The trapezoidal standing seam design enhances the panels' structural robustness and creates a modern, streamlined aesthetic. They come in three width options - 12, 18, and 24 inches - with a consistent 3-inch seam height and are available in both 22- and 24-gauge steel substrates. Manufacturers can finish these panels with premium coatings like Galvalume Plus, Signature 200, and Signature 300 to ensure lasting protection against environmental factors. For those seeking additional aesthetic customization, embossed finishes are also available. The panels' concealed fastening system employs various sliding clips, allowing for thermal movement while minimizing roof penetrations, thus maintaining structural integrity and weather resistance. With a minimum slope requirement of just ¼:12, Double-Lok panels are well-suited for low-slope roofing projects. They meet rigorous industry standards, boasting UL 580 and UL 790 Class A fire ratings and UL 2218 Class 4 impact ratings. Their Florida approval and Dade County rating for extreme weather conditions further underscore their versatility and durability. These panels are typically available in lengths up to 55 feet, with custom sizes possible upon request. Their watertight design and field-seamed connections make them a reliable choice for new constructions and retrofits, where enhanced weather performance and visual appeal are priorities. See the Snow Guards Compatibility Chart for Miller Steel Buildings Double-Lok Standing Seam Metal Roofing Panels.

This roof panel integrates seamlessly with a diverse array of our snow retention products, with a focus on our adhesive-mounted polycarbonate snow guards. Proper adhesive application is critical to prevent issues like detachment caused by moisture seepage and re-freezing. Our product range includes larger options such as IceJax II, Snojax II, and SnoBlox Ace, as well as more compact alternatives like SnoBlox Deuce and IceJax I. We offer SnowBreaker and SnowBreaker 3M variants to improve sliding snow and ice management. The panel's ribbed structure is compatible with various clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar rail systems. Installers can secure these components using stainless steel SnoBar clamps or aluminum RoofClamp options. We strongly recommend testing a clamp sample before finalizing your order to ensure optimal fit.

BattenLok HS Panels

BattenLok® HS panels represent a top-tier standing seam roofing solution that combines structural integrity with design flexibility. These panels feature a distinctive 2-inch vertical seam and are offered in 12, 16, and 18-inch widths, providing a contemporary look alongside robust performance. Crafted from high-quality 22- or 24-gauge steel, these panels are available with various surface treatments, including smooth and embossed finishes. The 16-inch panels can be further customized with optional striations or pencil ribs, adding visual depth to the roof's appearance. Advanced coating options such as Galvalume Plus®, Signature® 200, and Signature® 300 enhance the panels' durability, which offers superior protection against environmental wear. A key feature of the BattenLok HS system is its effective thermal expansion and contraction management, achieved through a hidden fastening mechanism that utilizes either fixed or floating clips. This design allows for the incorporation of various insulation thicknesses. It enables direct installation over purlins or bar joists, eliminating the need for a continuous substrate. With a minimal slope requirement of just ½:12, BattenLok HS panels are versatile enough for various applications, from industrial facilities to architecturally significant structures. The panels can be manufactured in lengths up to 55 feet or more, making them suitable for large-scale projects. Additional benefits include reduced oil canning, thanks to heavier gauge materials and structural enhancements like striations, ensuring these panels maintain their appearance and functionality even in challenging conditions. See the Snow Guards Compatibility Chart for Miller Steel Buildings BattenLok HS Standing Seam Metal Roofing Panels.

The advanced design of this roof panel system offers exceptional compatibility with a wide range of our snow retention solutions, particularly our adhesive-mounted polycarbonate snow guards. Ensuring proper adhesive application is vital to prevent potential issues such as detachment from moisture infiltration and subsequent re-freezing. Our product line includes robust options like IceJax II, Snojax II, and SnoBlox Ace, alongside more compact choices like SnoBlox Deuce and IceJax I. We've developed the SnowBreaker and SnowBreaker 3M variants for enhanced control over sliding snow and ice. The panel's distinctive ribbed structure accommodates various clamp-on snow guards, including the SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar rail systems. These can be securely attached using stainless steel SnoBar clamps or aluminum RoofClamp alternatives. We highly recommend testing a clamp sample before proceeding with your final order to guarantee an ideal fit for your application.

Miller Steel Buildings Compatibility Chart for Snow Guards

| Ultra-Dek Panel | Double-Lok Panel | BattenLok HS Panel | |

|---|---|---|---|

| IceJax I Glue Down | YES | YES | YES |

| IceJax II Glue Down | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES |

| SnoBlox Ace Glue Down | YES | YES | YES |

| Snojax II Glue Down | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES |

| SnowBreaker 3M | YES | YES | YES |

| SnoBar Standing Seam | YES | YES | YES |

| ColorBar Standing Seam | YES | YES | YES |

| SnoBar RCB-3 | YES | YES | YES |

| ColorBar RCB-3 | YES | YES | YES |

| SnoBar 2-Bar | YES | YES | YES |

| ColorBar 2-Bar | YES | YES | YES |

| SnoCleat RC | YES | YES | YES |

| SnoCleat RCT | YES | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by Miller Steel Buildings

Material-Specific Retention Strategies

Consider the unique properties of roofing materials such as aluminum and copper. These softer metals may necessitate additional rows of clamp-on guards or rails compared to more rigid steel roofing systems.

Aesthetic Snow Control Solutions

Enhance your roof's visual appeal by selecting retention systems that complement its design and color palette. Consider guards with matching metal inserts or color-coordinated systems. Budget-conscious homeowners might explore local finishing options or DIY coloring techniques.

Holistic Roof Protection Plan

Create a comprehensive strategy to safeguard your entire roof structure. Installers should distribute multiple rows of retention devices evenly to spread stress effectively. Utilize our spacing guidelines and calculation tools to optimize placement for maximum protective coverage.

Curved Surface Retention Innovations

Standard flat pad-style guards often struggle with curved surfaces. Roofing experts must devise inventive approaches for these distinctive architectural elements.

Regional Snowfall Analysis

When selecting a retention system, carefully evaluate your area's typical ground snow accumulation. While various guard styles may suffice in moderate snowfall regions, areas with heavier snowfall require specialized rail systems to prevent potential avalanches.

Copper Roof Protection Techniques

Exercise caution when installing guards on copper roofing. Avoid direct contact between adhesive-mounted pad-style guards and copper to prevent chemical reactions. For bar systems, apply protective layers before attaching them to copper surfaces to avoid interactions between dissimilar metals.

Advanced Fastening Techniques

Investigate cutting-edge attachment methods for metal standing seam roofs to preserve structural integrity. Consider seam-attached or adhesive-mounted solutions that maintain weatherproofing and adhere to warranty requirements.

Compatibility Verification

Thoroughly assess the compatibility of all system components with your specific roof type before installation. This crucial step prevents costly errors and ensures seamless integration. Consider testing individual components for a comprehensive compatibility assessment.

Strategic Adhesive Application

Schedule adhesive-mounted system installations during suitable temperature windows. Factor in ambient temperature fluctuations when estimating curing times, noting that high-quality adhesives may require extended bonding periods under moderate conditions.

Ice Management Integration

Incorporate specialized elements like IceStoppers into your retention systems, particularly in ice-prone areas. Carefully choose and position these components, paying special attention to roofs with higher seams to effectively address ice-related challenges.

Conclusion

SnoBlox-Snojax has positioned itself as a front-runner in the snow retention industry by adopting a comprehensive strategy that prioritizes enduring solutions through extensive support and education. Rather than merely selling products, we equip our customers with essential knowledge and resources for effective implementation. This dedication is evident in our personalized assistance and diverse online materials. Customers can easily access guidance and solutions through direct communication with our support team. To enhance user experience, we have developed practical tools, including a detailed buyer's guide and an informative page on best practices. We actively encourage customers to seek assistance with order and installation support. By emphasizing education and support, we ensure positive experiences and optimal outcomes for all users of our snow guard installations. Our commitment to quality and customer satisfaction drives continuous improvements in products and support services. This unwavering dedication has established us as a trusted partner in snow retention solutions, offering products and a complete package of expertise and support. Through this holistic approach, we have cemented our position as an industry leader, providing customers with the tools and knowledge necessary to achieve superior results with our snow retention systems.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.