Snow Guards For Dean Steel Buildings Standing Seam Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Nov 1st 2024

See the Snow Guards Compatibility Chart for Dean Steel Buildings Standing Seam Metal Roofing.

Are Snow Guards Really Necessary for Dean Steel Buildings Concealed Fastener Metal Roofs?

Winter presents specific challenges for buildings with standing seam metal roofs, primarily due to the risk of unexpected snow and ice slides.

These sudden avalanches can harm individuals, pets, and nearby structures. The smooth surface of these roofs makes it more likely for snow and ice to slip off, highlighting the importance of implementing effective snow retention strategies for safety. Contractors can tailor snow guards and rail systems to suit various roof designs, thereby enhancing safety. When installing these systems, it is essential to consider factors such as the roof's pitch, panel layout, and local climate conditions. Property owners have access to a range of educational resources that can assist them in making informed decisions about snow retention solutions. Focusing on educational materials like our informative blog posts and innovative solutions can significantly reduce the risks associated with snow and ice buildup, creating safer environments in regions prone to heavy snowfall. This proactive approach directly addresses the winter-related challenges faced by buildings with standing seam metal roofs, ultimately safeguarding people and property from potential harm. Property owners can ensure a safer winter season for everyone near their buildings by implementing appropriate snow retention measures.

Standing Seam Metal Roof Panels by Dean Steel Buildings

Dean Steel Buildings has established itself as a prominent player in the metal building industry over the past five decades. Dean Steel has grown significantly since its founding in 1972, expanding its operations to fabricate its buildings and serve markets throughout the Southeastern United States, the Caribbean, and Central and South America. As a member of the Metal Building Manufacturers Association, the company actively follows the stringent quality management standards established by the International Accreditation Service AC472. Dean Steel Buildings earned AC-472 accreditation for all its facilities on December 21, 2010, demonstrating its commitment to these high standards. The company's commitment to quality is evident in its structural roof and wall panels, which undergo extensive testing to meet industry standards. Dean Steel's innovative approach to design and construction is supported by advanced computer-aided technology, allowing for exceptional flexibility in project execution. Their portfolio encompasses many structures, from large commercial and industrial facilities to office buildings, shopping centers, banks, and residential properties. Dean Steel Buildings has built a strong reputation among architects and contractors thanks to its focus on traditional quality, reliability, and personalized service. Dean Steel coats its metal panels with high-performance materials that provide excellent resistance to weathering, corrosion, and fading. These coatings have extensive warranties, guaranteeing clients long-lasting, low-maintenance roofing and siding solutions.

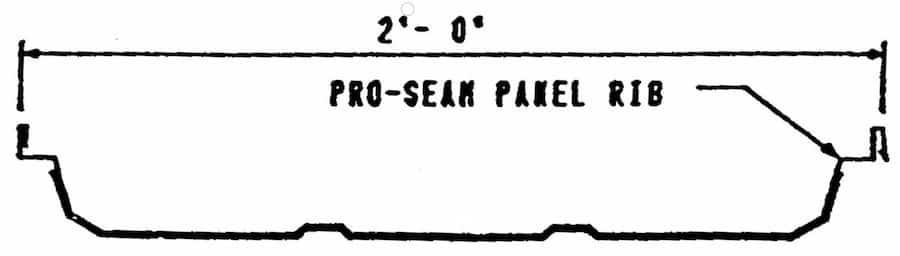

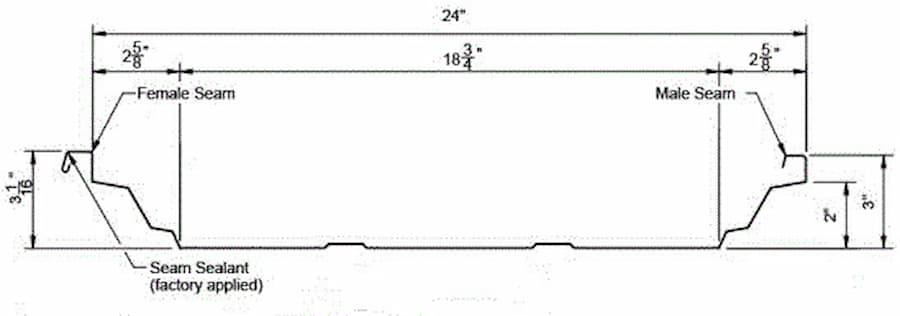

Pro Seam Panels

Dean Steel's Pro Seam Panels are a robust roofing solution for high performance. Made from 24-gauge steel, these panels are 24 inches wide and feature a 3-inch seam height, providing exceptional durability against severe weather conditions such as wind, rain, and hurricanes. The Pro Seam Panels offer three seaming options: RollLok™, TripleLok™, and QuadLok™. These options allow customization based on the project's wind uplift requirements, enabling hand-seaming at clip locations, field seaming for a watertight seal, or utilizing QuadLok™ for maximum resistance in high-wind areas. Each seaming method ensures the roof maintains a sleek appearance while performing optimally against harsh elements. When considering installation on low-pitch roofs, it is crucial to account for potential issues like water ponding and snow or ice accumulation. It is advisable to avoid pitches below 2:12 in regions with heavy snowfall to prevent ice dam formation. In areas prone to heavy rain, such as the Gulf Coast, a roof pitch greater than 4:12 is recommended to minimize water buildup and ensure adequate drainage. See the Snow Guards Compatibility Chart for Dean Steel Buildings Pro Seam Standing Seam Metal Roofing.

Our snow retention solutions are particularly well-suited for this specific roofing system, with a strong emphasis on our adhesive-mounted polycarbonate snow guards. Proper adhesive application is crucial to avoid problems like refreezing and moisture-induced detachment. We provide a wide range of snow guard models, including larger options such as IceJax II, Snojax II, and SnoBlox Ace, as well as more compact choices like the SnoBlox Deuce and IceJax I. For enhanced protection during snow and ice-shedding events, we offer SnowBreaker and SnowBreaker 3M models. The design of the panel's ribs allows for clamp-on snow guards, such as the SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar rail systems. These can be attached using stainless steel SnoBar clamps or aluminum RoofClamp alternatives. We advise conducting a test fit with a clamp sample before ordering these systems. It's worth noting that additional rows of rails may be necessary when installing snow guards on aluminum or copper roof panels compared to steel options. These materials have lower rigidity and require extra support to ensure adequate strength and stability.

Pro Lok Panels

The Pro Lok Roof System is a robust, reliable solution for industrial and commercial roofing needs. This system withstands extreme weather conditions and accommodates significant expansion and contraction, making it an ideal choice for demanding environments. With its focus on water resistance and longevity, the Pro Lok panel excels in challenging situations, minimizing the need for frequent maintenance or repairs due to leaks. It's crucial to note that the Pro Lok system requires precise specifications by a qualified building designer who understands the unique requirements of each project. This roofing system provides long-lasting protection and stability when properly matched to the building design. The Pro Lok panel features a 3-inch seam height with ribs on 24" spacing. Manufacturers typically produce it using 24-gauge steel, but they can also use 22-gauge steel, aluminum, or copper to meet specific project needs. Like the Pro Seam Panels, the Pro Lok Roof System offers three seaming methods: RollLok™, TripleLok™, and QuadLok™. These options provide varying levels of wind uplift resistance, allowing for customization based on the roof's exposure to environmental factors. The QuadLok™ method offers enhanced reinforcement and is particularly useful for roof corners or areas prone to high winds. To address potential snow and ice accumulation issues, special considerations are necessary for low-pitch roofs, especially those with a slope less than 2:12. This practice is critical in regions experiencing heavy snowfall or long roof runs, such as the Gulf Coast, where intense rainstorms are common. The Pro Lok system has a minimum recommended slope of 1/2:12, with any lower slopes requiring special approval. Ultimately, the goal of a well-designed roof is to effectively manage water runoff and prevent pooling, ensuring the longevity and performance of the structure. See the Snow Guards Compatibility Chart for Dean Steel Buildings Pro Lok Standing Seam Metal Roofing.

Our comprehensive range of snow retention solutions is ideally suited for this roofing system, with a particular emphasis on our adhesive-mounted polycarbonate snow guards. Correct adhesive application is crucial to prevent issues like refreezing and moisture-related detachment. We offer various snow guard models to cater to different needs. Options such as IceJax II, Snojax II, and SnoBlox Ace are available for larger applications. At the same time, more compact solutions include the SnoBlox Deuce and IceJax I. For those seeking enhanced protection during snow and ice-shedding events, we provide SnowBreaker and SnowBreaker 3M models. The design of the panel's ribs is compatible with clamp-on snow guards, including various rail systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These can be secured using stainless steel SnoBar clamps or aluminum RoofClamp alternatives. We recommend conducting a test fit with a clamp sample before ordering these systems. It's important to note that when installing snow guards on aluminum or copper roof panels, additional rows of rails may be necessary compared to steel options. This fact is due to the lower rigidity of these materials, which requires extra support to ensure adequate strength and stability.

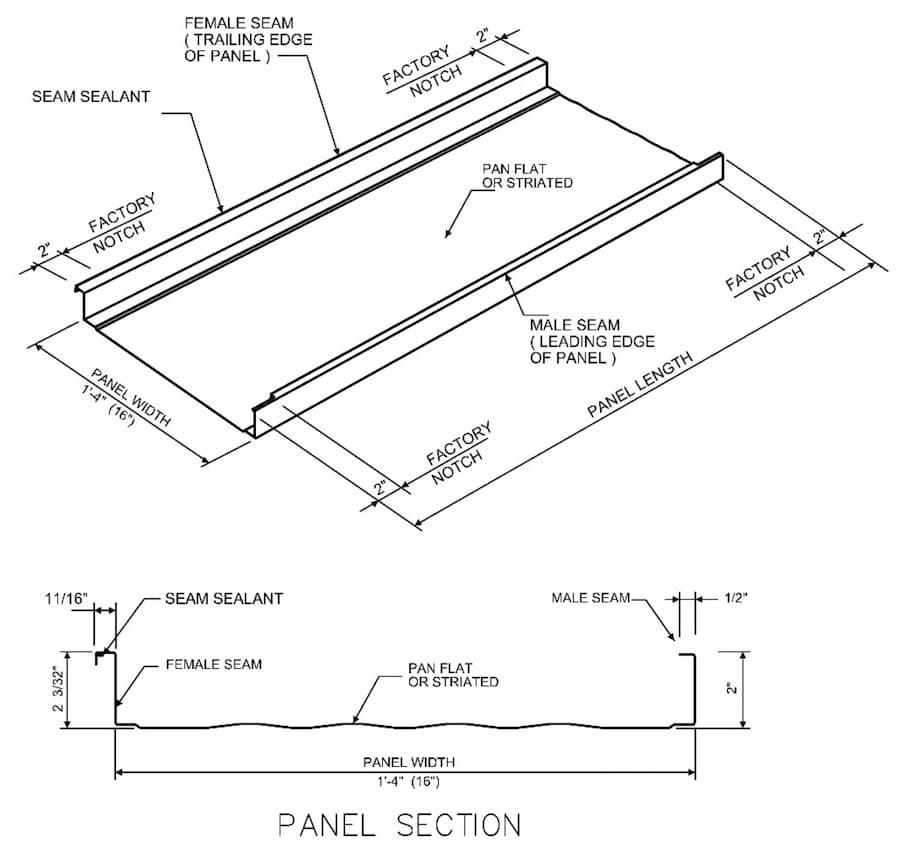

Pro-VR Panels

Dean Steel's Pro-VR Panels offer a robust structural roofing solution that eliminates the need for a solid substrate between purlins. These 16-inch wide panels feature a 2-inch seam height, combining strength and ease of installation. Crafted from 24-gauge steel with a 50,000 psi minimum yield strength, these panels prioritize performance and simplicity. The roofing system employs galvanized floating clips for attachment, allowing natural expansion and contraction while maintaining weather resistance. A specialized non-drying sealant applied to the seams ensures long-term flexibility and watertightness. The design minimizes visible fasteners, with color-matched, self-drilling screws used only at panel end laps for enhanced strength and aesthetics. Pro-VR Panels have undergone rigorous testing, meeting ASTM E1592 and Factory Mutual 4471 standards for wind uplift resistance. Their durability is further validated by Florida Product Approval #16423.1, demonstrating their ability to withstand severe weather conditions. See the Snow Guards Compatibility Chart for Dean Steel Buildings Pro-VR Standing Seam Metal Roofing.

Our extensive selection of snow retention products is ideally designed for this specific roofing configuration, focusing on our adhesive-mounted polycarbonate snow guards. Proper adhesive application is essential to avoid problems such as refreezing and moisture-induced separation. We provide diverse snow guard models to meet various requirements, ranging from larger options like IceJax II, Snojax II, and SnoBlox Ace to more compact solutions like SnoBlox Deuce and IceJax I. For those requiring additional protection during snow and ice-shedding events, we offer SnowBreaker and SnowBreaker 3M variants. The panel's rib design is compatible with clamp-on snow guards, including several rail systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These can be attached using stainless steel SnoBar clamps or aluminum RoofClamp alternatives. We advise conducting a test fit with a clamp sample before ordering these systems. It's worth noting that when installing snow guards on aluminum or copper roof panels, additional rows of rails may be necessary compared to steel options due to the lower rigidity of these materials, which requires extra support to ensure adequate strength and stability.

Dean Steel Buildings Compatibility Chart for Snow Guards

| Pro Seam Profile | Pro Lok Profile | Pro-VR Profile | |

|---|---|---|---|

| IceJax I Glue Down | YES | YES | YES |

| IceJax II Glue Down | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES |

| SnoBlox Ace Glue Down | YES | YES | YES |

| Snojax II Glue Down | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES |

| SnowBreaker 3M | YES | YES | YES |

| SnoBar Standing Seam | YES | YES | YES |

| ColorBar Standing Seam | YES | YES | YES |

| SnoBar RCB-3 | YES | YES | YES |

| ColorBar RCB-3 | YES | YES | YES |

| SnoBar 2-Bar | YES | YES | YES |

| ColorBar 2-Bar | YES | YES | YES |

| SnoCleat RC | YES | YES | YES |

| SnoCleat RCT | YES | YES | YES |

Considerations for Adding Snow Guards to Standing Seam Roofs by Dean Steel Buildings

Develop a Comprehensive Roof Protection Plan

Create a holistic strategy to safeguard your entire roof surface. Install multiple rows of evenly distributed snow retention elements to prevent stress concentration in specific areas. Use resources like our spacing guidelines and quote request tools to determine the best placement for optimal protection.

Customize Snow Retention Systems for Visual Appeal

Enhance your roof's appearance by choosing snow retention systems that match its color scheme and design. Explore options such as custom powder-coated guards or products with color-matched metal inserts. For a budget-friendly approach, consider local powder coating services or apply paint to the guards yourself.

Adapt Your Snow Management Strategy to Local Climate Conditions

Before selecting a system, investigate your area's ground snow load. Simple rail setups or pad-style guards may suffice in regions with moderate snowfall (below 45 psf ground load). Consider more robust rail systems for areas experiencing heavier snowfall to ensure adequate protection.

Schedule Adhesive-Based System Installation Strategically

Plan to install adhesive-mounted systems during warmer months, preferably late spring or early summer. Consider ambient temperatures when estimating curing times for optimal bonding. High-quality adhesives like Surebond SB-190 require extended curing periods at moderate temperatures—specifically, 28 days at 50°F or above.

Verify System Compatibility Through Pre-Installation Testing

Before installation, test the system components' fittings to ensure compatibility with your roof type. This essential step helps prevent costly mistakes and ensures smooth integration. Consider purchasing individual system parts and accessories separately to facilitate testing.

Address Ice-Related Challenges with Specialized Components

In regions prone to icing, incorporate dedicated elements like IceStopper snow rail accessories into your snow retention setup. Properly selecting and placing these components is crucial, especially for roofs with higher seams, to combat ice-related issues effectively.

Protect Roof Integrity with Appropriate Attachment Methods

When choosing attachment methods, prioritize options that maintain your roof's structural integrity, particularly for standing seam metal roofing. Investigate non-penetrating, surface-mounted solutions such as clamp-on or adhesive-based systems to preserve weatherproofing and warranty conditions.

Conclusion

SnoBlox-Snojax adopts a comprehensive approach to snow guard solutions, focusing on enduring effectiveness rather than temporary remedies. Our core philosophy is providing exceptional customer support, ensuring each client fully grasps our product range. We extend beyond product sales, offering a robust support framework with individualized assistance and a wealth of online resources. This strategy equips our customers with the necessary knowledge and tools for successful installations. Our readily available support team will address inquiries or concerns, providing direct communication channels for clients seeking guidance. We have also developed practical guides and resources to help customers maximize the potential of our products, including a Snow Guard Buyer's Guide and a detailed "What Works and What Doesn't" page to aid in decision-making. We actively encourage customers to contact our support team via phone or email for assistance with orders or installations. By prioritizing customer education and support, we strive to ensure that every SnoBlox-Snojax client has a positive experience and achieves optimal results with their snow guard installations. Our unwavering commitment to quality and customer satisfaction drives us to continually enhance our products and support services, establishing us as a trusted partner in snow retention solutions.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.