Snow Guards For Exposed Fastener Metal Roof Panels by Butler Manufacturing

Posted by Derek Gamble - SnoBlox-Snojax Specialist on May 31st 2024

See the Snow Guards Compatibility Chart for Butler Building Systems Exposed Fastener Metal Roofing.

"What Are the Best Snow Guards for Metal Roofs?"

When it comes to exposed fastener metal roofs, protecting your property, loved ones, and pets from the dangers of avalanching snow and ice is crucial. These roofing systems often require specialized snow retention solutions to effectively tackle the challenges of harsh winter weather. This comprehensive guide presents various snow guard options compatible with Butler's exposed fastener metal panel, helping you make an informed decision tailored to your roof system's needs. As part of an ongoing blog series, we'll highlight top metal panel manufacturers and recommend compatible snow guard solutions. Our goal is to provide you with the confidence and expertise to navigate this process smoothly, enabling you to make well-informed choices that protect your investment and ensure your property's and its occupants' safety. We offer detailed information to assist you in selecting the most appropriate snow guard system, guaranteeing optimal protection and peace of mind during harsh winter conditions.

Exposed Fastener Metal Roof Panels by Butler Manufacturing

With roots stretching back over a century to 1901, Butler Manufacturing has carved a pioneering path in the metal building industry. Founded in Kansas City, Missouri, by Emanuel Norquist, Charles Butler, and Newton Butler, the company initially focused on producing agricultural products like galvanized steel stock tanks. However, a pivotal shift occurred in 1909 when Emanuel Norquist's need for a garage to house his automobile prompted his brother Victor to construct the first Butler building using corrugated galvanized steel, marking the company's entry into the metal building sector. During the economic challenges of the Great Depression in the 1930s, Butler demonstrated its manufacturing prowess by securing a massive order from the U.S. Department of Agriculture for over 30,000 steel grain bins. This achievement paved the way for further innovations, including the introduction of their groundbreaking rigid frame building design in 1939, which revolutionized metal building construction methods. In the following decades, Butler continued to push boundaries, unveiling pioneering products like the MR-24 standing seam metal roof system and the Butlerib II roof and wall systems in 1969, which became their flagship offerings. Strategic acquisitions further fueled the company's growth, such as the 1984 purchase of Howmet Architectural Products, a manufacturer of architectural aluminum products, from Alumax Aluminum Corporation, which was subsequently renamed Vistawall. In 2004, Butler Manufacturing was acquired by BlueScope Steel Limited, an Australian company, solidifying BlueScope's position as a leader in pre-engineered metal buildings in North America and China. Throughout its storied history, Butler has been renowned for its groundbreaking innovations in metal building design, engineering, and construction, cementing its status as a significant force in the industry.

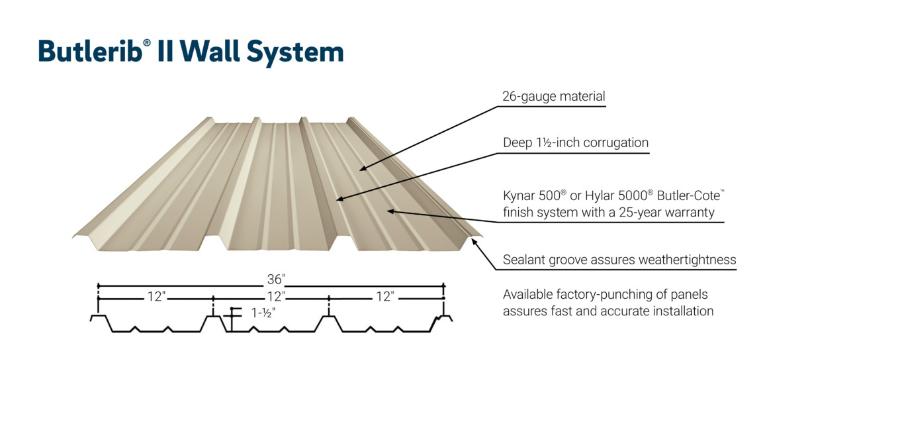

Butlerib® II Roof System

Industry experts widely regard the Butlerib® II as the premier through-fastened roof system. This roofing solution offers exceptional value, emphasizing cost-effective installation and low maintenance requirements. As the foundational roof system for Butler's renowned Widespan™ structural system, the Butlerib® II boasts a robust 1½-inch corrugation profile with 12" rib spacing and a 36" coverage width, contributing to its unparalleled strength and durability. This panel is available in 24 or 26-gauge steel and lengths up to 40'. One of the standout features of this roof system is its pre-punched design, which ensures precise endlap alignment and streamlines the installation process. Additionally, the factory-slotted holes allow for seamless expansion and contraction during seasonal temperature fluctuations, minimizing wear and tear over time. The pre-formed sealant grooves enhance the system's weathertight performance by promoting accurate sealant placement between panels. The Butlerib® II's unique "return leg" full side-lap corrugation provides exceptional support at the panel side laps. At the same time, Butler's exclusive Lock-Rivet™ fastener reinforces the system's weathertight capabilities. See the Snow Guards Compatibility Chart for Butler Building Systems Butlerib II Metal Roofing.

Moreover, the roof system can be easily insulated with fiberglass blanket insulation or the ThermaLiner™ insulation system, offering superior energy efficiency and thermal performance. Backed by an array of certifications and warranties, including a UL Class 90 wind uplift rating, U.S. Army Corps testing, FM Global approval, and Miami-Dade County certification, the Butlerib® II roof system exemplifies Butler Manufacturing's commitment to quality and reliability. With a 10-year weathertightness warranty option, this robust roofing solution is a testament to Butler's dedication to delivering exceptional value and long-lasting performance in the metal building industry.

The Butlerib® II panel is versatile for snow guard installations, seamlessly integrating with many snow guard systems. Compatible options include screw-down SnoBar and ColorBar snow rail systems, SnoCleat PBR, and the comprehensive lineup of stainless steel SnowCatcher designs, such as the standard rectangle shape and decorative Kodiak, Maple Leaf, Fleur-de-lis, Sun Burst, and Mustang models. Polycarbonate snow guards, commonly used with this panel, offer the flexibility of adhesive and screw-down installation methods, except for the Snojax I, which requires mechanical fastening. Larger models like the SnoBlox Ace and Icejax II are popular for use on the Butlerib® II panel. At the same time, some customers may prefer smaller guards like the SnoBlox Deuce. These guards retain snow and ice on the roof. For controlled shedding, we recommend the SnowBreaker and SnowBreaker 3M guards. When installing snow guards with mechanical fasteners, it is crucial to secure them by screwing them down through the low flats of the panel and into a sturdy underlying structure. This approach ensures maximum strength and effectiveness. Mounting screw-down individual snow guards or rail systems onto the high ribs of the panel is strongly discouraged, as it can compromise the installation's integrity and performance. For comprehensive guidance on correct mounting techniques, refer to our blog titled "Mounting Snow Guards on the High Ribs or the Panel Flats: Which is Correct?" This resource provides valuable insights and best practices for a successful, long-lasting snow guard installation.

Butler Snow Guard Compatibility Chart

| IceJax I Screw Down | YES |

|---|---|

| IceJax I Glue Down | YES |

| IceJax II Screw Down | YES |

| IceJax II Glue Down | YES |

| SnoBlox Deuce Screw Down | YES |

| SnoBlox Deuce Glue Down | YES |

| SnoBlox Ace Screw Down | YES |

| SnoBlox Ace Glue Down | YES |

| Snojax I Screw Down | YES |

| Snojax II Screw Down | YES |

| Snojax II Glue Down | YES |

| SnowBreaker 3M | YES |

| SnowBreaker Screw Down | YES |

| SnowBreaker Glue Down | YES |

| SnowCatcher | YES |

| Decorative SnowCatcher | YES |

| SnoCleat PBR | YES |

| SnoCleat 2.67 | NO |

| SnoBar PBR | YES |

| ColorBar PBR | YES |

| SnoBar 2.67 | NO |

| ColorBar 2.67 | NO |

Considerations for Snow Guard Installation on Butler Exposed Fastener Metal Roofing

1. Layout Planning

Carefully plan the layout of your snow retention system, adhering to the manufacturer's recommended guidelines. Our website offers complimentary spacing charts and custom layout quote requests for our bar systems and individual pad-style snow guards. Exercise caution and avoid positioning snow guards in isolated areas, such as above doors, HVAC units, or chimneys, as this often leads to overloading and failure of the snow retention system, regardless of type.

2. Color Coordination

Explore our color-matching options to integrate our metal snow guards with your roof's aesthetic. The SnoCleat PBR, SnoCleat 2.67, and ColorBar rail system are compatible with slide-in color strips, which you can purchase or create from leftover roofing material. Alternatively, opt for custom powder coating in your desired color, with a typical turnaround time of 3 to 4 weeks. Suppose you require a quicker solution or prefer greater color control. In that case, you can powder coat or paint the guards locally after delivery.

3. Safeguarding Roof Integrity

Prevent potential leaks by utilizing products like SnoCleat PBR, SnoCleat 2.67, SnowCatchers, and screw-down rails, which come equipped with butyl gaskets that create a secure seal when used in conjunction with our Master Gripper/Driller screws and neoprene washers. For added peace of mind, some customers apply an extra bead of silicone sealant. When working with polycarbonate guards, use a neutral-curing silicone to seal the entire base, allowing it to ooze around the edges before smoothing with a gloved finger. We recommend the NovaFlex MR150 sealant.

4. Adhesive Installation Timing

You can install screw-down snow guards and rails year-round if your roof has no snow, ice, or debris. However, you must carefully time the installation of adhesive-mounted guards. Our SureBond SB-190 adhesive for polycarbonate guards requires approximately 28 days at 50°F to cure fully. Late spring or early summer is typically the ideal installation period across most of the U.S. and Canada. Colder temperatures will pause the curing process until it warms up again. Rain won't affect the adhesive after 24 hours, but avoid using SB-190 on copper roofs, as the adhesive and metal might react, leading to premature corrosion.

5. Secure Fastening Techniques

When screwing in snow guards, ensure you're penetrating at least 1" of solid wood decking, purlins, or added blocking. For pre-engineered metal buildings, fasten them to the metal purlins whenever possible. Avoid simply screwing into the panels, as this could lead to potential issues. If you cannot easily add blocking and your ground snow load is 45 psf or less, consider switching to adhesive-mounted snow guards instead.

6. Ground Snow Load Awareness

Ground Snow Load refers to the maximum snow weight your roof can withstand. You can obtain this information online, consult your building plans, or inquire with local authorities about your area's specific number. For ground snow loads under 45 psf, you can utilize adhesive or screw-mounted individual guards and bars. However, we recommend exclusively employing snow rail systems for loads exceeding that threshold.

Conclusion

SnoBlox-Snojax works to deliver an outstanding customer experience while you select and install your snow guards. Our knowledgeable support team is readily available to address any inquiries or concerns. Feel free to contact us via email at support@snojax.com or by phone at 1-800-766-5291. We have curated valuable resources to empower our customers, including our comprehensive Snow Guard Buyer's Guide and the insightful "What Works and Doesn't" page. These resources will equip you with the information to make informed decisions and ensure a seamless installation process.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.