Snow Guards For Inland Building Systems Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Dec 9th 2024

See the Snow Guards Compatibility Chart for Inland Building Systems Screw Down Metal Roofing Panels.

Are Snow Guards Necessary for Inland Building Systems Screw Down Metal Roofing?

Winter poses unique challenges for buildings with exposed fastener metal roofs, particularly the danger of abrupt snow and ice slides.

The slick nature of these roofs enhances the possibility of snow avalanches, which can endanger people, animals, and surrounding property. Experts developed specialized snow retention solutions for metal roofing to address this issue. These innovative systems, which incorporate adjustable snow guards and rail systems, are engineered to accommodate various metal roof designs, effectively managing snow accumulation and offering tailored solutions for different structures. When implementing these protective measures, it's crucial to consider several factors, including the roof's slope, panel configuration, and local weather patterns. Various educational resources are available to assist property owners in making well-informed decisions. These include blog posts, informative web pages, and a comprehensive list of compatible metal panel manufacturers for snow retention solutions. Focusing on education and innovative approaches, we aim to reduce the risks associated with snow and ice buildup, fostering safer environments in regions that experience heavy snowfall.

Exposed Fastener Metal Roof Panels by Inland Building Systems

Inland Building Systems has a rich heritage in the metal building industry, tracing its roots back to 1910. Initially a part of Inland Steel Corporation headquartered in Deerfield, Illinois, the company has undergone significant transformations. A pivotal moment came in 1974 when Inland Steel merged its metal building division with Ryerson Corporation, forming INRYCO and establishing a manufacturing facility in Cullman, Alabama. The INRYCO name persisted until 1986 when Inland Steel divested the business. Following this, the company experienced several ownership transitions, including acquisitions by Dubin and Clark and later Behlen Manufacturing Company. In 2008, Inland Building Systems found a new home under the umbrella of Schulte Building Systems. This move further solidified its reputation for quality and customer service. Today, Inland is a prominent supplier in the metal building industry, offering custom-engineered systems across all fifty states and over thirty countries. The company's client roster boasts industry giants such as Coca-Cola, Ford Motor Company, Anheuser-Busch, and the United States Armed Forces, all of whom rely on Inland for robust building solutions. Priding itself on timely and budget-conscious project delivery, Inland manages the entire process from initial inquiry to completion. Their product line includes standing seam roof systems and various other building components. With more than six decades of experience and an unwavering commitment to excellence, Inland Building Systems continues to be a trusted name in the metal building sector.

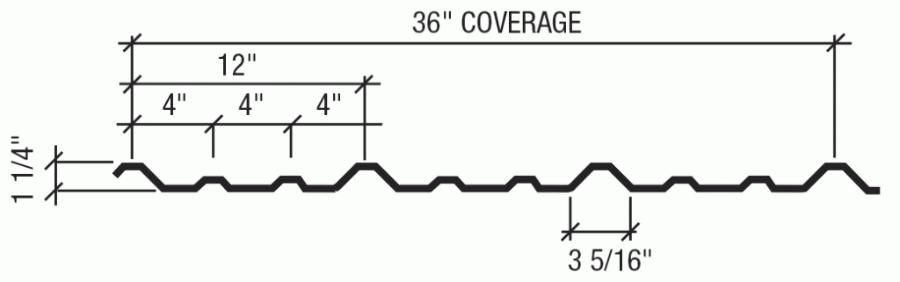

PBR

The PBR panel stands out as a highly adaptable metal component in the construction industry, finding its place in various applications. This panel proves its worth across commercial, industrial, and agricultural structures, from roofing to walls, liners, mansards, and soffits. Its design boasts a generous 36-inch coverage width. This feature streamlines the installation process and potentially cuts time and labor expenses. The major ribs of the panel, which are 1-¼" deep and positioned at 12-inch intervals, create its distinctive appearance. This configuration creates an aesthetically pleasing shadowed effect. Two minor ones are nestled between these prominent ribs, enhancing the panel's overall strength and stability. This thoughtful design bolsters the structural integrity and ensures efficient water drainage. Renowned for its resilience and ability to withstand harsh weather conditions, the PBR panel meets or surpasses industry benchmarks. It demonstrates impressive load-bearing capabilities and resistance to wind forces. The panel's broad coverage contributes to a sleek visual appeal while minimizing the number of seams, thereby improving weather protection and energy conservation. Its versatility extends to compatibility with various insulation systems and other building elements. Builders favor it for new constructions and renovation projects across different building types. See the Snow Guards Compatibility Chart for Inland Building Systems PBR Screw Down Metal Roofing Panels.

The PBR panel system presents a versatile and comprehensive approach to snow guard installation, accommodating various models and designs. This adaptable system encompasses multiple options, from screw-down solutions like SnoBar and ColorBar rail systems to specialized alternatives like SnoCleat PBR and stainless steel SnowCatcher designs. Experts recommend using screws or adhesives to install most polycarbonate snow guards. They favor Surebond SB-190 for its superior bonding qualities. It's worth noting, however, that this specific adhesive is not suitable for metal pad-style guards. Proper placement is crucial for optimal performance, and different models have particular guidelines. Installers should avoid attaching snow guards directly to the panel's high ribs to ensure maximum stability and strength. Instead, securing the snow guards through the panel's low flats into a solid underlying structure is the most effective method. This approach guarantees a robust and reliable snow retention system capable of withstanding harsh winter conditions. By adhering to these guidelines, installers can create a snow guard system that effectively protects against the potential hazards of snow and ice accumulation on roofs.

Inland Building Systems Compatibility Chart for Snow Guards

| PBR Panel | |

|---|---|

| IceJax I Screw Down | YES |

| IceJax I Glue Down | YES |

| IceJax II Screw Down | YES |

| IceJax II Glue Down | YES |

| SnoBlox Deuce Screw Down | YES |

| SnoBlox Deuce Glue Down | YES |

| SnoBlox Ace Screw Down | YES |

| SnoBlox Ace Glue Down | YES |

| Snojax I Screw Down | YES |

| Snojax II Screw Down | YES |

| Snojax II Glue Down | YES |

| SnowBreaker 3M | YES |

| SnowBreaker Screw Down | YES |

| SnowBreaker Glue Down | YES |

| SnowCatcher | YES |

| Decorative SnowCatcher | YES |

| SnoCleat PBR | YES |

| SnoCleat 2.67 | NO |

| SnoBar PBR | YES |

| ColorBar PBR | YES |

| SnoBar 2.67 | NO |

| ColorBar 2.67 | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Inland Building Systems

Evaluating Roof Capacity for Snow

Start by examining your roof's ability to handle snow accumulation. Review regional weather data to guide your choice of snow retention system. For areas with moderate snowfall, simple guards or screw-down rails might suffice. Heavier snow regions necessitate more substantial rail systems.

Optimal Installation Timing

For adhesive-mounted snow guards in North America, aim to install them during late spring or early summer. This timing allows proper curing of adhesives like Surebond SB-190, which requires about a month of temperatures above 50°F. While rain isn't a concern after the first day, cold weather can hinder curing.

Addressing Curved Roof Issues

Curved or radiused roof panels present unique challenges for snow retention. Traditional pad-style guards may not adhere properly to these surfaces. Explore alternative solutions to ensure effective snow management on non-flat roofs.

Effective Guard Placement

The positioning of snow guards is crucial for their performance. Avoid concentrating guards in specific areas, which can lead to overloading and potential system failure. Instead, aim for an even distribution across the roof surface.

Blending Aesthetics with Functionality

Consider the visual impact of snow guards on your roof design. Look for customizable options to match your roof's appearance, such as color-matched inserts or powder-coated finishes. While DIY solutions are available, professional powder coating often offers superior durability and aesthetics.

Ensuring Proper Mounting

Secure attachment is vital for mechanically mounted systems. Aim to fasten snow guards to a solid substrate, preferably using at least an inch of sturdy wood like plywood decking or purlins. Attaching directly to metal purlins is preferable to relying solely on the roof panel on metal roofs. Consider adhesive-mounted options if reinforcing weaker roofs isn't feasible.

Preventing Water Infiltration

Proper application of silicone sealant is crucial when installing screw-mounted polycarbonate snow guards. Adequate pressure ensures complete coverage at the base and eliminates air pockets. While many metal guards and rail brackets include waterproof gaskets, some installers add sealant around the edges for additional protection. However, this may not always be necessary.

Conclusion

SnoBlox-Snojax takes pride in offering outstanding support for snow guard installations, focusing on durable solutions rather than quick fixes. Our primary objective is to ensure our clients fully grasp our product range. We skillfully blend individualized support with various resources, equipping customers with the necessary knowledge and tools for effective implementation. Clients can take advantage of our offerings through direct communication with our support team and by utilizing our practical guides. Our steadfast dedication to quality and practical effectiveness underscores our commitment to delivering top-tier solutions, reflecting our passion for product excellence and customer satisfaction. We've created valuable resources such as a Snow Guard Buyer's Guide and a "What Works and What Doesn't" page to aid clients in making well-informed decisions. These materials offer crucial insights and practical information to facilitate the decision-making process. We actively encourage customers who need help with their orders to contact our support team via phone or email, ensuring they receive the necessary guidance to achieve the best results with our snow guard products.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.