Snow Guards For Smith-Built Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 25th 2025

See the Snow Guards Compatibility Chart for Smith-Built Screw Down Metal Roofing Panels.

What are the best snow guards for Smith-Built exposed fastener roofs?

In winter, buildings with metal roofs that use exposed fasteners often experience sudden snow and ice slides. This quick movement, known as a roof avalanche, can create various issues for the structure and area around it.

Metal roofs have a slick surface that enables snow and ice to slide off rapidly, sometimes posing risks to people, pets, and property below. To address these dangers, snow retention solutions are available from our company that fit a wide variety of popular roofing designs. The selection includes adjustable snow guards and customizable rail systems that work with different roof pitches, metal panel profiles, and local climate conditions. Comprehensive support comes from our resources, such as blog articles, step-by-step installation instructions, and regularly updated lists of compatible manufacturers. In regions with significant snowfall, these snow retention systems play a vital role in reducing the dangers of ice buildup and improving safety, offering dependable protection and peace of mind throughout the winter.

Exposed Fastener Metal Roof Panels by Smith-Built

Founded in 2003, Smith-Built Metals has become a reputable manufacturer specializing in metal roofing and building systems. Based in Atlanta, Georgia, and operating additional locations in Macon, Albany, and Columbia, the company caters to residential, agricultural, and commercial clients. Originally concentrating on producing and installing metal buildings, Smith-Built Metals has expanded to become one of the region's largest manufacturers. The company is recognized for using premium materials and skilled craftsmanship, offering products like Master Rib panels, R panels, and standing seam panels—all backed by a 40-year paint warranty. In addition to roofing, they supply pre-engineered metal buildings for various industries, including agriculture, retail, industrial, and institutional sectors. With hundreds of projects completed, Smith-Built Metals is a top choice for contractors and property owners who want durable, cost-effective roofing solutions. Their streamlined "Order Today, Pickup Tomorrow" service allows for quick material access, whether by pickup or delivery. The company emphasizes personalized customer service, encouraging clients to visit their facilities and consult with knowledgeable staff about product options and installation. Committed to reliability, quality, and prompt service, Smith-Built Metals continues to grow its reach throughout Georgia and surrounding areas.

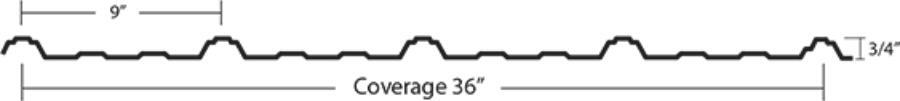

Master Rib Panel

Smith-Built's MasterRib Panel is a reliable and attractive roofing solution commonly selected for residential, small commercial, pole barn, and agricultural projects due to its strength, energy efficiency, and appealing look. Often referred to as the Ag Panel, it is these buildings' most widely used profile. Each panel covers a width of 36 inches and can be manufactured in custom lengths from 3 feet up to 60 feet, offering flexibility for different project requirements. The panels feature trapezoidal ribs spaced 9 inches apart and have a rib height of 3/4 inch, contributing to their structural integrity and distinctive appearance. Available in 26 and 29-gauge steel, installers mount the panels over 1"x 4" wood furring strips, with the option to include insulation or other materials underneath. Their design allows for easy overlapping, and an anti-siphon groove helps guard against water intrusion. High-quality, color-matched fasteners secure both the panels and trim. Customers can choose from 20 color options, all covered by a 40-year paint warranty. At the same time, the panels last even longer and come with a 40-year limited warranty. Smith-Built recommends installation on roofs with a minimum slope of 1/12. Smith-Built Metals encourages customers to contact or visit in person for more information and a free project quote. See the Snow Guards Compatibility Chart for Smith-Built Master Rib Screw Down Metal Roofing Panels.

This panel supports various snow retention systems, offering versatility in installation methods and material selections. Polycarbonate options like the SnoBlox Deuce and SnowBreaker fit between the panel's minor ribs. For those opting for metal solutions, screw-mounted products like the SnoCleat PBR and any of the six SnowCatcher styles attach to the flat center section, which is considered the best location for mounting. Other choices, including the Snojax I and Icejax I, are intended to straddle the minor ribs; Icejax I can be installed with either adhesive or screws, while Snojax I requires mechanical fasteners. The panel is compatible with Tall ColorBrackets and the appropriate hardware for installing aluminum ColorBar PBR or galvanized SnoBar PBR snow rail systems. This wide-ranging compatibility ensures dependable snow management across different weather and environmental conditions.

R Panel

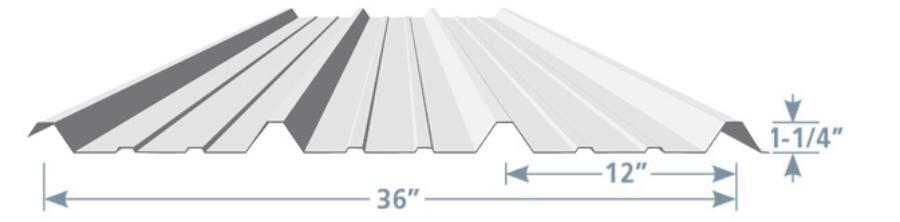

Smith-Built's R-Panel is a versatile metal system designed for roofing and siding, offering notable strength and energy efficiency. Featuring 1 ¼-inch trapezoidal ribs spaced 12 inches apart, this panel is engineered for durability and effective water resistance, making it suitable for various applications such as commercial buildings, steel structures, and institutional projects. The panel provides a 36-inch coverage width, can be used on slopes as low as 1:12, and comes in a 26-gauge thickness. It is compatible with open framing and solid substrates, with lengths ranging from 3 to 60 feet. Customers can choose from 20 color options, all backed by a 40-year limited warranty. The R-Panel is typically attached to metal purlins or hat channels using color-matched self-drilling fasteners for installation. Smith-Built also supplies structural steel components for these projects. Those interested in learning more are encouraged to contact one of Smith-Built's three locations. See the Snow Guards Compatibility Chart for Smith-Built R Panel Screw Down Metal Roofing Panels.

This panel is highly adaptable for snow guard installation, making it a suitable choice for various projects and accommodating different installer preferences. It is compatible with several snow guard systems, including screw-fastened rail options like SnoBar, ColorBar, and SnoCleat PBR. The panel also accommodates various stainless steel SnowCatchers in unique designs such as Standard Rectangle, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak. Most polycarbonate snow guards can be installed on these panels using either adhesive or screws. However, the Snojax I model specifically requires screw-down installation. When using adhesive for polycarbonate snow guards, it is crucial to select Surebond SB-190, the recommended industry standard, and avoid using this adhesive with metal pad-style snow guards. For optimal placement, position smaller snow guards between the minor ribs at the center of the panel. Certain models, like Snojax II and Icejax II, must be installed off-center, straddling a minor rib or mesa on either side. It is important not to attach snow guards or rails directly to the high ribs; instead, they should be installed through the flat, lower sections and anchored into a solid substrate below for a secure and durable installation.

Smith-Built Compatibility Chart for Snow Guards

| Master Rib Panel | R Panel | |

|---|---|---|

| IceJax I Screw Down | YES | YES |

| IceJax I Glue Down | YES | YES |

| IceJax II Screw Down | NO | YES |

| IceJax II Glue Down | NO | YES |

| SnoBlox Deuce Screw Down | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES |

| SnoBlox Ace Screw Down | NO | YES |

| SnoBlox Ace Glue Down | NO | YES |

| Snojax I Screw Down | YES | YES |

| Snojax II Screw Down | NO | YES |

| Snojax II Glue Down | NO | YES |

| SnowBreaker 3M | YES | YES |

| SnowBreaker Screw Down | YES | YES |

| SnowBreaker Glue Down | YES | YES |

| SnowCatcher | YES | YES |

| Decorative SnowCatcher | YES | YES |

| SnoCleat PBR | YES | YES |

| SnoCleat 2.67 | NO | NO |

| SnoBar PBR | YES | YES |

| ColorBar PBR | YES | YES |

| SnoBar 2.67 | NO | NO |

| ColorBar 2.67 | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Smith-Built

Test-Fit Components Before Full Installation

Conduct a preliminary assembly of snow guard parts to ensure they are compatible with your roof’s contours. Ordering and trying out sample units beforehand helps you spot and address any fitting or alignment issues early in the project.

Adapt Snow Guard Placement for Roofing Type

Tailor your installation method to the specific roofing material. Softer metals like aluminum or copper typically need snow guards spaced more closely together—and possibly in additional rows—than harder materials such as steel. Confirm that all finishes and coatings are compatible to prevent adverse reactions between different metals.

Coordinate Snow Guard Finish with Roof Design

Select snow guards with finishes or coatings that blend with your roof's style and color scheme. Powder-coated finishes or custom color inserts can help achieve a unified, attractive look. Professional finishes provide extra durability, but DIY solutions may be more budget-friendly.

Secure Snow Guards to Structural Supports

For maximum strength, anchor snow guards to the building’s structural framework—such as wood rafters or metal purlins—instead of just the roof panels. If the underlying structure isn’t robust enough, reinforce it with extra bracing or consider specialized adhesives to boost stability.

Use Sealant for Improved Water Resistance

When installing polycarbonate snow guards with screws, cover the entire base with silicone sealant. This step closes air gaps, enhances resistance to water intrusion, and helps prevent leaks.

Select Snow Guards for Special Roof Shapes

Standard snow guards may not work effectively on arched, radiuses or unusually shaped roofs. Choose products designed for unique roof profiles to ensure reliable snow retention and protect the roof structure. Consulting the roof panel manufacturer can help identify the best solution.

Schedule Adhesive Installations for Warm Conditions

If you’re using adhesive to attach snow guards, plan the work for late spring or early summer, when daytime temperatures are consistently above 50°F for several weeks. This warmth is necessary for proper adhesive curing, as colder weather can slow the process. After the first 24 hours, rain typically does not affect the adhesive’s performance.

Conclusion

SnoBlox-Snojax focuses on delivering reliable and durable snow guard solutions, emphasizing lasting performance rather than short-term fixes. Our company builds customer confidence by offering personalized support and making product information easy to access, including clear installation guidelines. Our clients receive direct assistance and useful tools, such as our Snow Guard Buyer's Guide and detailed product comparisons, which help streamline their choices. Our knowledgeable team can provide tailored advice and help with orders by phone or email. SnoBlox-Snojax empowers customers to select, install, and maintain their snow guard systems with assurance through a dedication to expert guidance, open communication, and high-quality products.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.