Snow Guards For Standing Seam Metal Roof Panels by Butler Manufacturing

Posted by Derek Gamble - SnoBlox-Snojax Specialist on May 29th 2024

See the Snow Guards Compatibility Chart for Butler Building Systems Standing Seam Metal Roofing.

Installing snow guards and snow retention systems on concealed fastener standing seam metal roofs is a crucial step to pay attention to. Failing to take this precaution could expose your property, loved ones, and pets to the dangers of avalanching roof snow and ice. The unique designs of different metal roof panels often necessitate specialized snow guard solutions to combat these winter weather challenges effectively. This practical guide presents a range of snow guard options compatible with Butler's standing seam metal panels, equipping you with the knowledge to make an informed decision tailored to the specific needs of your roof system. As part of an ongoing series, these blogs will highlight top metal panel manufacturers and recommend compatible snow guard solutions. The overarching goal is to provide you with the confidence and expertise to navigate this process smoothly, enabling you to make well-informed choices that protect your investment and ensure your property's and its occupants' safety. We offer detailed information to assist you in selecting the most appropriate snow guard system, guaranteeing optimal protection and peace of mind during harsh winter conditions.

Standing Seam Metal Roof Panels by Butler Manufacturing

Butler Manufacturing has a rich legacy as a trailblazer in the metal building industry, with its origins dating back over a century to 1901. The company was established in Kansas City, Missouri, by Emanuel Norquist, Charles Butler, and Newton Butler, initially focusing on producing agricultural products like galvanized steel stock tanks. However, a pivotal moment came in 1909 when Emanuel Norquist required a garage for his automobile, prompting his brother Victor to construct the first Butler building utilizing corrugated galvanized steel, thus marking the company's foray into the metal building sector. During the economic hardships of the Great Depression in the 1930s, Butler demonstrated its manufacturing prowess by securing a massive order from the U.S. Department of Agriculture for over 30,000 steel grain bins. This achievement paved the way for further innovations, including the introduction of their groundbreaking rigid frame building design in 1939, which revolutionized metal building construction methods. In the following decades, Butler continued to blaze new trails, unveiling pioneering products like the MR-24 standing seam metal roof system and the Butlerib II wall system in 1969, which became their flagship offerings. The company's strategic acquisitions further bolstered its growth trajectory. One example was the 1984 purchase of Howmet Architectural Products, a manufacturer of architectural aluminum products, from Alumax Aluminum Corporation. Butler then renamed the company Vistawall. In 2004, Butler Manufacturing was acquired by BlueScope Steel Limited, an Australian company, solidifying BlueScope's position as a leader in pre-engineered metal buildings in North America and China. Throughout its storied history, Butler has been renowned for its groundbreaking innovations in metal building design, engineering, and construction, cementing its status as a significant force in the industry.

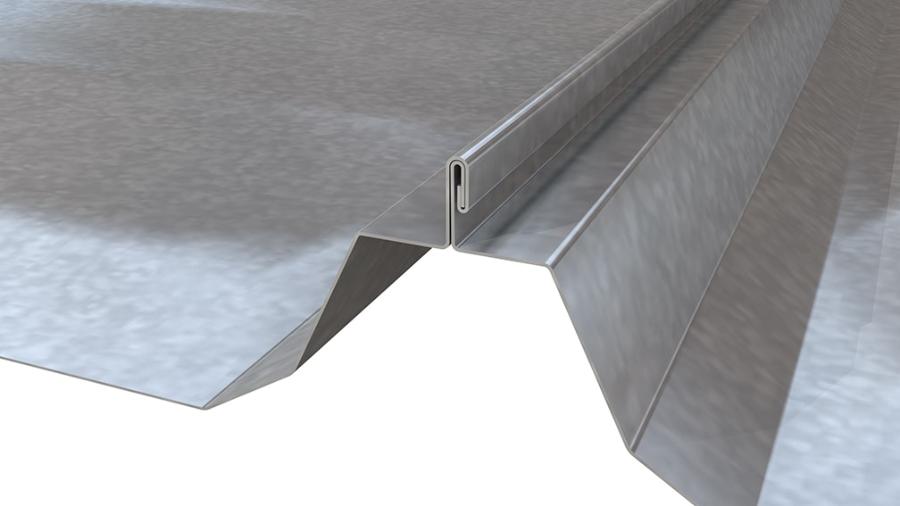

MR-24 Roof Panel

The MR-24 is a premium standing seam metal roof system renowned for its exceptional weathertight performance and durability. Its proprietary double-locked seam design is a standout feature, creating a complete 360-degree Pittsburgh double-lock seam akin to those used in gasoline tanks and beverage cans for unrivaled seam integrity. Butler boasts that this robust seam far outperforms competitors' crimped or snapped panel seams that are susceptible to wind uplift and roof traffic stresses. The MR-24 panels feature 24 inches of coverage, a 2¾" rib height, and thickness options of 22 and 24 gauge available. These sturdy panels integrate patented high-strength stainless steel roof clips into their side laps. The innovative clips glide along a triangular bar, allowing unrestricted thermal movement without binding, unlike some systems that restrict expansion/contraction. Butler achieves precise panel alignment with their factory-punched structural framing with pre-located holes for proper clip and panel positioning. This meticulous process guarantees weathertight integrity that Butler claims field-drilled screws cannot match. The MR-24 also utilizes a staggered, two-piece clamped splice design located over structural members that prevents leak vulnerabilities from adjacent splices converging while providing reinforced support. Through its robust double-locked seam, free-moving clip system, precise factory alignment, and reinforced splice design across multiple width/gauge options, the Butler MR-24 delivers best-in-class weathertightness, durability, and wind resistance capabilities for standing seam metal roofs. See the Snow Guards Compatibility Chart for Butler Building Systems MR-24 Standing Seam Metal Roofing.

The MR-24 Standing Seam Roof System is ideal for installing adhesive-mounted polycarbonate snow guards due to its wide seam spacing and flat pan design. Proper adhesive application is crucial to prevent moisture intrusion, which could lead to refreezing and potential detachment issues. Customers have multiple snow and ice retention options on their roofs. Larger solutions like the IceJax II, Snojax II, and SnoBlox Ace provide robust protection. At the same time, smaller alternatives, such as the SnoBlox Deuce and IceJax I, offer more compact options for snow retention. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable pieces, reducing the risk of large, dangerous avalanches. The panel's rib shape ensures compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems. These systems offer flexibility in attachment options, with modified stainless steel SnoBar Clamps or standard aluminum RoofClamp attachment options featuring cupped tip set screws. When using the stainless steel SnoBar clamp with the SnoBar or ColorBar snow retention systems, we modify these clamps to accommodate the shorter vertical seam of the MR-24 roof system. Because the standard SnoBar clamp utilizes a single set screw on either side, this clamp could rock forward without this modification when used on the MR-24 panel. This process involves welding a stainless steel spacer to the top of the interior. When finished, we refer to this product as the "MR-24 Clamp." These specialized clamps are typically not kept in stock. We produce them per order.

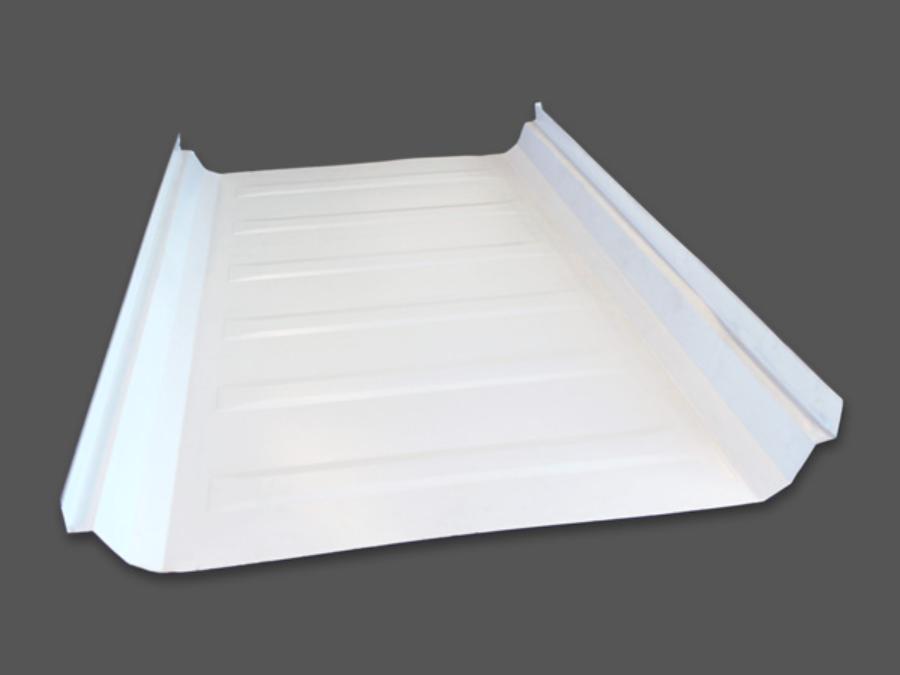

CMR-24 Roof Panel

The CMR-24 is a high-performance standing seam roof system that builds upon the proven MR-24 roof system, offering enhanced energy efficiency, a polished interior appearance, and additional insulation and liner components. At its core, the CMR-24 employs the same exclusive panel seaming process and clip system as the MR-24. It features a robust 360-degree Pittsburgh double-lock seam for superior weathertightness. The panel width is 24 inches and is offered in 22-gauge and 24-gauge options, providing flexibility in terms of strength and durability. A key aspect of the CMR-24 is its specially engineered bearing plate, which evenly distributes the weight of the roof panels and clips across the structural steel members, ensuring optimal load distribution. Energy efficiency is a priority, with the system incorporating high-quality rigid insulation boards available in various thicknesses and insulating values, allowing for customized thermal performance. In addition to the insulation, the CMR-24 includes an interior metal liner that protects the insulation and provides a sleek, finished look to the building's interior while contributing to its overall energy performance. Aesthetically, the system features the same visually appealing 2¾" rib height, adding architectural interest to the roof's profile. Designed with durability and low maintenance in mind, the CMR-24 can save up to 90% on roof maintenance costs compared to other systems. It meets stringent safety standards, including the U.L. Class 90 wind uplift rating, U.S. Army Corps testing, F.M. Global approval, and Miami-Dade County approval, ensuring reliable performance in demanding environments. Furthermore, the system has several cool color options, which help reduce heat absorption and contribute to energy savings. Overall, the Butler CMR-24 Roof System combines the proven weathertight performance of the MR-24 with enhanced energy efficiency, interior aesthetics, added insulation and liner components, and a range of panel dimensions and gauges, making it a comprehensive and customizable roofing solution for commercial and industrial applications. See the Snow Guards Compatibility Chart for Butler Building Systems CMR-24 Standing Seam Metal Roofing.

The CMR-24's exterior dimensions and styling are identical to the standard MR-24 panels. As such, this standing seam roof system is an excellent option for installing adhesive-mounted polycarbonate snow guards. Its wide seam spacing and flat pan design make it an ideal choice. Proper adhesive application is crucial to prevent moisture intrusion, which could lead to refreezing and potential detachment issues. Customers have various snow and ice retention options on their roofs. Larger solutions like the IceJax II, Snojax II, and SnoBlox Ace provide robust protection against snow and ice buildup. The SnoBlox Deuce and IceJax I offer smaller alternatives for effective snow retention for those seeking more compact options. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable pieces, reducing the risk of large, dangerous avalanches. The panel's rib shape ensures compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems. These systems offer flexibility in attachment options, with modified stainless steel SnoBar Clamps or standard aluminum RoofClamp attachment options featuring cupped tip set screws. When using the stainless steel SnoBar clamp with the SnoBar or ColorBar snow retention systems, we must alter these clamps to accommodate the shorter vertical rib of the MR-24 roof system. Because the standard SnoBar clamp utilizes a single set screw on either side, this clamp could rock forward without modification when used on the MR-24 panel. We weld a stainless steel spacer to the top of the clamp's interior to address this issue and refer to the resulting product as the MR-24 Clamp. These clamps are typically not kept in stock. We produce them per order to ensure a perfect fit for the MR-24 Standing Seam Roof System.

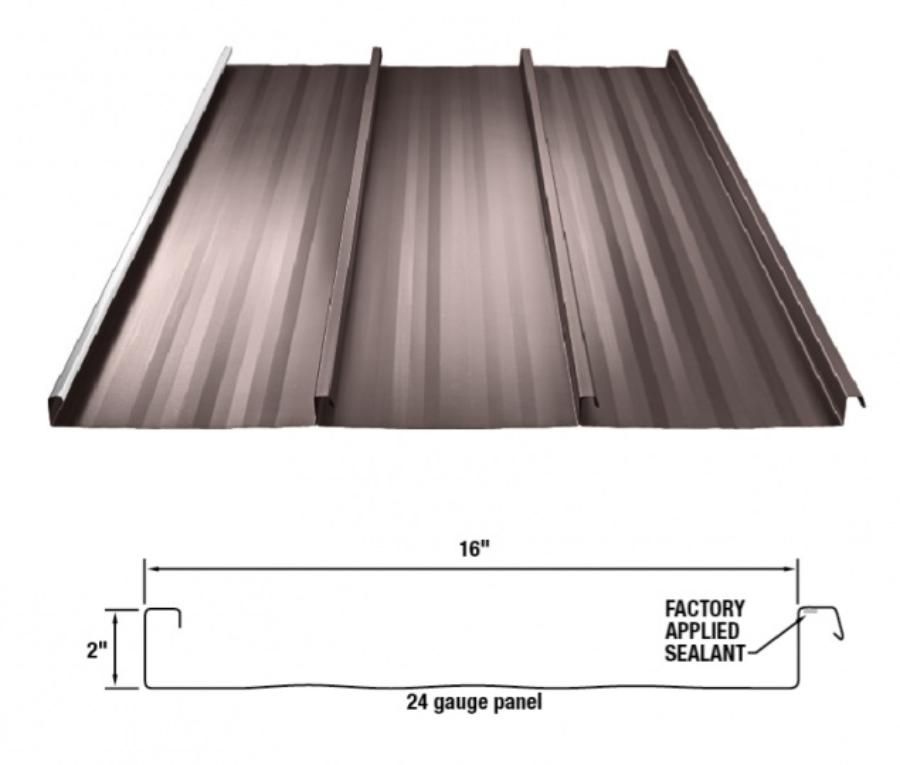

VSR II™ Architectural Roof Panel

The VSR II™ Architectural Roof System from Butler is a visually striking standing seam metal roof engineered for architectural projects where the roofline is a prominent design element. This innovative system seamlessly blends form and function, offering a sleek, modern aesthetic while delivering exceptional weather resistance and durability. Crafted with meticulous attention to detail, the VSR II features interlocking panels that are mechanically seamed together rather than relying on snaps or battens. This construction method ensures a weathertight seal, safeguarding against the elements and providing long-lasting protection. The movable clip system also accommodates thermal expansion and contraction, allowing for up to 2 inches of movement, further enhancing the roof's resilience. The VSR II's versatility is one of its standout features. This 24-gauge steel panel has 16-inch spacing and a 2" rib height. The VSR II offers a customizable solution that harmonizes with the overall design aesthetic, from schools and churches to commercial buildings with visible roofs and fascia applications. Backed by Butler's legacy of over 50 years of proven performance in the roofing industry, the VSR II is a testament to the company's commitment to addressing the critical concerns of architects, builders, and owners. With a wide array of color and finish options, this architectural roof system allows for personalized touches that elevate the visual appeal of any project. By seamlessly integrating weathertight construction, thermal movement accommodation, and customizable design elements, the VSR II™ Architectural Roof System from Butler sets a new standard for architectural roofing solutions, delivering exceptional performance and unparalleled aesthetic appeal. See the Snow Guards Compatibility Chart for Butler Building Systems VSR II Standing Seam Metal Roofing.

The VSR II™ Standing Seam Roof System presents an excellent choice for installing adhesive-mounted polycarbonate snow guards. Proper adhesive application prevents moisture intrusion, refreezing, and potential detachment issues. Customers can select from options tailored to various snow and ice retention needs. For comprehensive retention, larger solutions like the IceJax II, Snojax II, and SnoBlox Ace are available, while smaller alternatives such as the SnoBlox Deuce and IceJax I cater to roofs with less severe conditions. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable chunks. The panel's rib shape ensures compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems, offering flexibility in attachment options with standard stainless steel SnoBar Clamps or aluminum RoofClamp attachment options featuring cupped tip set screws. When using adhesive-mounted polycarbonate snow guards with this panel, a thicker application of Surebond SB-190 adhesive may be necessary to compensate for the panel's striations, ensuring a secure and reliable installation.

Butler Snow Guard Compatibility Chart

| MR-24 Profile | CMR-24 Profile | VSR II Profile | |

|---|---|---|---|

| IceJax I Glue Down | YES | YES | YES |

| IceJax II Glue Down | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES |

| SnoBlox Ace Glue Down | YES | YES | YES |

| Snojax II Glue Down | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES |

| SnowBreaker 3M | YES | YES | YES |

| SnoBar Standing Seam | YES (Modified) | YES (Modified) | YES |

| ColorBar Standing Seam | YES (Modified) | YES (Modified) | YES |

| SnoBar RCB-3 | YES | YES | YES |

| ColorBar RCB-3 | YES | YES | YES |

| SnoBar 2-Bar | YES | YES | YES |

| ColorBar 2-Bar | YES | YES | YES |

| SnoCleat RC | YES | YES | YES |

| SnoCleat RCT | YES | YES | YES |

Ensuring Optimal Snow Guard Performance on Butler Standing Seam Roofs

A Proper Layout is Vital

The performance of any snow retention system hinges on the layout. We offer complimentary guidance, resources, spacing charts, and custom quote request forms. An effective system should span the entire roof, typically with multiple ascending rows, to distribute weight evenly. Install individual guards in a staggered pattern and mount rails in straight lines. Avoid isolated installations, as this can overload the system and cause failure. If using SnowBreaker, which features a different rule set for isolated placement, follow our specific installation guidelines.

Test Fittings for Compatibility

Before committing to a system, test-fit any snow guards, clamps, brackets, or IceStoppers to ensure compatibility with your project. You can order samples from our website without minimum requirements, including 20" and 27" bar sample kits. Testing upfront prevents costly mistakes.

Timing for Adhesive-Mounted Guards

You can install clamps and rails year-round, but you must carefully time the installation of glue-down polycarbonate snow guards. The industry-standard adhesive, Surebond SB-190, requires around 28 days at 50°F to cure fully. Plan adhesive installations in the U.S. and Canada for optimal results in late spring or early summer. Rain should not be an issue after 24 hours. We do not recommend using SB-190 on copper roofs due to potential corrosion caused by chemical reactions.

Consider IceStopper Attachments

For SnoBar or ColorBar rail systems on standing seam roofs, we highly recommend adding IceStopper attachments—especially over walkways, entrances, and parking areas. IceStoppers can be installed initially or retrofitted later. Proper spacing is critical for effectively managing snow and ice buildup. They become even more important for seams over 1" tall, as ice can slide under the bar without IceStopper protection.

Know Your Local Snow Load

Knowing your area's ground snow load is crucial when selecting snow retention systems for metal roofs. While most individual guards and rails can handle up to 45 psf (pounds per square foot) without issues, heavier snowfall areas require the exclusive use of our more robust snow rail solutions. If your roof panels cannot accommodate rails and the load exceeds 45 psf, consult the manufacturer for their recommended approach. Contact your building inspector or search online for "[your town] ground snow load."

Color-Matching for Seamless Appearance

Our metal snow retention products can be color-matched to your roof for a clean, integrated look. SnoCleat RC, SnoCleat RCT, and ColorBar Snow Rail Systems use slide-in metal strips that blend the system's face with your roof color. You can purchase these strips with the system or create them from leftover roofing materials on-site. We also offer custom powder coating, which blends the system with your roof but may add extra lead time and cost.

Avoid Screwing Into Standing Seam Metal Roofs

Installing screw-down snow guards or rails on standing seam metal roofs can lead to disastrous consequences due to the roof's expansion and contraction. This incorrect installation practice risks damaging your panels, causing leaks, costly repairs, and voided warranties. Use clamp-on or adhesive-mounted systems for standing seams to ensure a secure, compatible installation.

Conclusion

SnoBlox-Snojax works to deliver an outstanding customer experience while you select and install your snow guards. Our knowledgeable support team is readily available to address any inquiries or concerns. Feel free to contact us via email at support@snojax.com or by phone at 1-800-766-5291. We have curated valuable resources to empower our customers, including our comprehensive Snow Guard Buyer's Guide and the insightful "What Works and Doesn't" page. These resources will equip you with the information to make informed decisions and ensure a seamless installation process.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.