Snow Guards For Exposed Fastener Metal Roof Panels by Ceco Building Systems

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 10th 2024

See the Snow Guards Compatibility Chart for Ceco Buildings Screw Down Metal Roofing Panels.

"What Are the Best Snow Guards for Metal Roofs?"

If you have an exposed fastener metal roof system, it's crucial to protect your property, loved ones, and pets from the potential dangers posed by sliding snow and ice. These types of roofs often require snow retention solutions designed to withstand the harsh conditions of winter. This blog delves into various snow guard options compatible with exposed fastener metal roofs manufactured by Ceco, assisting you in selecting the most suitable solution for your roof system. As part of an ongoing series, we'll highlight prominent metal panel manufacturers and recommend compatible snow retention solutions. Our objective is to equip you with the knowledge and confidence to navigate this process seamlessly, empowering you to make informed decisions that safeguard your investment and ensure the safety of all during the brutal winter months.

Exposed Fastener Metal Roof Panels by Ceco Building Systems

In the post-war era of 1947, C.L. Mitchell embarked on an ambitious venture by establishing Ceco Building Systems. With a clear vision and a dedicated team of eleven employees, he set out to revolutionize the construction industry, aiming to make erecting buildings a more rewarding experience for clients. As the 1960s dawned, Ceco emerged as a trailblazer in the metal building sector, spearheading a transformative journey that saw the company evolve from simple shade and shelter projects to highly customized and architecturally-focused structures. Mitchell's pioneering spirit and inventions laid the groundwork for Ceco's enduring legacy. During this decade of innovation, Ceco led the industry by introducing uniform building pricing, developing the standing seam roof, offering in-house construction services, and leveraging the power of computers for designing and estimating buildings. This forward-thinking approach solidified the company's position as a front-runner in the field. In the early 1990s, Mitchell's proteges built upon his teachings, implementing the first personal computer-based software for builders' offices to design and price projects. They also expanded the product line to include more architecturally sensitive roof and wall panel profiles, further enhancing the company's offerings and cementing its reputation for innovation. In 2006, Robertson-Ceco Corporation was acquired by NCI Building Systems, now known as Cornerstone Building Brands. This acquisition propelled Cornerstone Building Brands to become North America's leading manufacturer of exterior building products. Today, Ceco is renowned for its sophisticated capabilities in highly complex metal building projects.

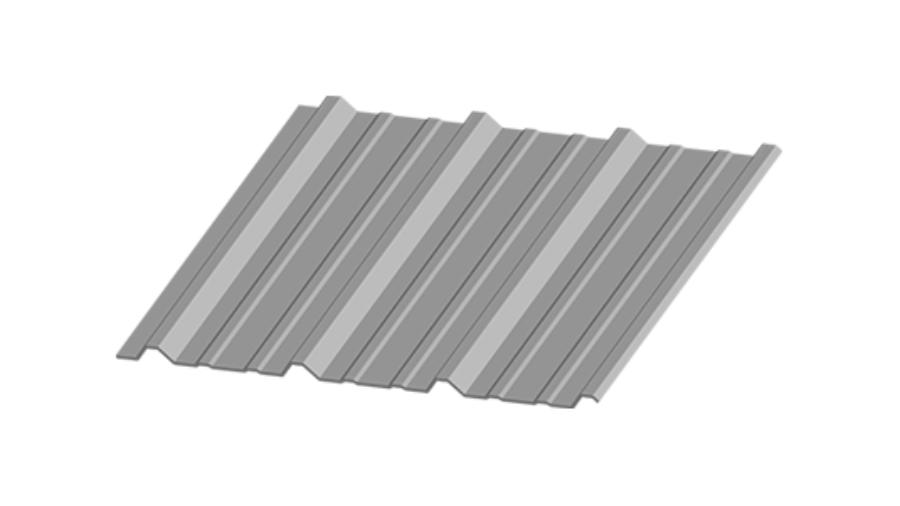

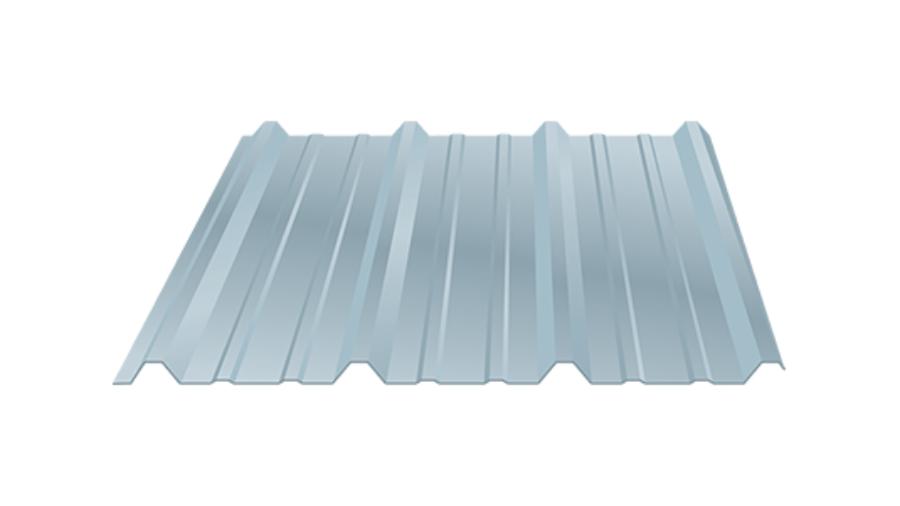

PBR Metal Roof Panel

The PBR (Purlin Bearing Roof) metal panel, commonly referred to as an R-panel, is a versatile offering from Ceco Building Systems. This ribbed panel features a striking, symmetrical profile with deep, evenly-spaced ribs and exposed fasteners for roofing and wall applications. This panel is 36 inches wide with a rib height of 1-1/4 inches. The ribs have an on-center spacing of 12 inches. Ceco Building Systems offers the PBR panel in two steel gauge options: 24 gauge (0.0276 inches thick) and 26 gauge (0.0179 inches thick), ensuring durability and longevity. Ceco engineered the PBR panel for superior performance beyond its visually appealing design. See the Snow Guards Compatibility Chart for Ceco Buildings PBR Screw Down Metal Roofing Panels.

The reinforced areas between the ribs fortify the building envelope, enhancing its strength and weather resistance. Additionally, the panel is wind uplift rated and qualifies for UL Class 90 construction under multiple construction numbers, providing fire resistance and added safety. Installation of the PBR panel is straightforward, thanks to its well-designed profile, which also enhances the diaphragm capabilities for purlin stability. This feature, combined with the panel's sleek appearance and weather-resistant properties, makes it an excellent choice for roofing and wall systems in various building projects.

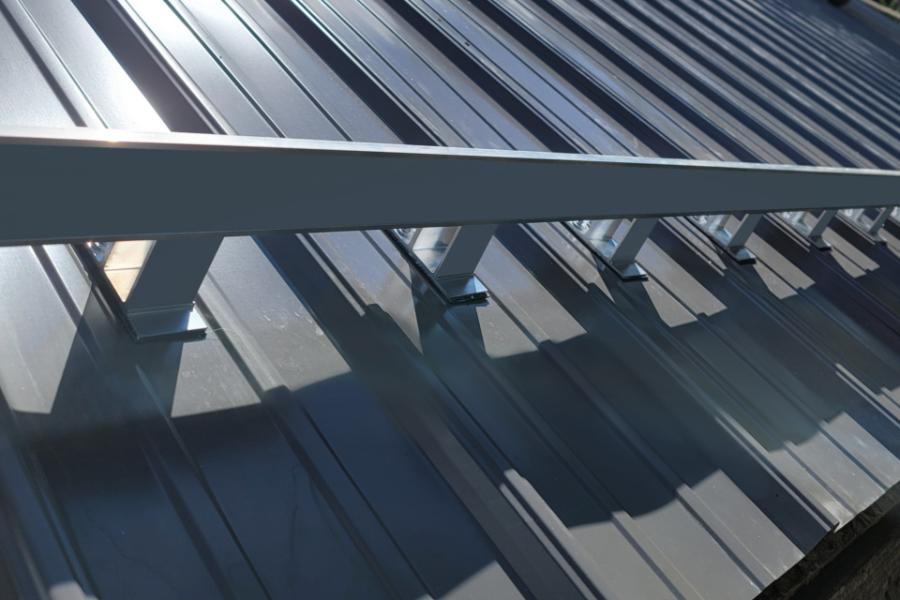

PBR panels offer remarkable adaptability when installing snow guards, catering to diverse preferences and requirements. These panels integrate with a wide array of snow guard models, including the screw-down SnoBar and ColorBar snow rail systems, SnoCleat PBR, and the stainless steel SnowCatchers, including the Standard Rectangle, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak designs. Additionally, most polycarbonate snow guard models, except for the Snojax I, can be affixed to these panels using adhesive or mechanical fasteners. It's crucial to note that the Snojax I requires installation with only mechanical fasteners. You must use the Surebond SB-190 adhesive when working with polycarbonate models because its formulation ensures compatibility with these materials. However, this adhesive is not suitable for metal pad-style snow guards. Installers should mount smaller snow guards between the minor ribs, centered on the panels, for optimal installation. Specific models, such as the Snojax II and Icejax II, require off-center mounting, straddling either the left or right minor rib and consistent placement over the same rib is crucial in these cases. It is essential to avoid securing individual snow guards or rail systems directly onto the high ribs of the panel. Instead, the recommended approach is to fasten them by screwing through the panel's low flats into a solid underlying structure, ensuring maximum installation strength and stability.

Ceco Building Systems Snow Guard Compatibility Chart

| PBR Profile | |

|---|---|

| IceJax I Screw Down | YES |

| IceJax I Glue Down | YES |

| IceJax II Screw Down | YES |

| IceJax II Glue Down | YES |

| SnoBlox Deuce Screw Down | YES |

| SnoBlox Deuce Glue Down | YES |

| SnoBlox Ace Screw Down | YES |

| SnoBlox Ace Glue Down | YES |

| Snojax I Screw Down | YES |

| Snojax II Screw Down | YES |

| Snojax II Glue Down | YES |

| SnowBreaker 3M | YES |

| SnowBreaker Screw Down | YES |

| SnowBreaker Glue Down | YES |

| SnowCatcher | YES |

| Decorative SnowCatcher | YES |

| SnoCleat PBR | YES |

| SnoCleat 2.67 | NO |

| SnoBar PBR | YES |

| ColorBar PBR | YES |

| SnoBar 2.67 | NO |

| ColorBar 2.67 | NO |

Considerations for Purchasing and Installing Snow Guards for Ceco Exposed Fastener Metal Roofing

1. Ensuring Proper Color Integration

We provide various color-matching solutions for our snow retention systems to achieve a cohesive and visually appealing installation. These solutions include interchangeable color strips that can be easily slid into our SnoCleat and ColorBar products, allowing you to match the snow guards' faces with your roof's hue. Additionally, we offer powder-coating services for all metal snow guards, ensuring a precise color match to your specifications. While powder-coated products require a longer lead time of 3 to 4 weeks due to the custom manufacturing process, customers also have the option to have their snow guards powder-coated locally or painted on-site for a quicker turnaround and greater flexibility in color selection.

2. Comprehensive Layout Planning

Regardless of your snow retention system, obtaining a design recommendation from the manufacturer is crucial. We provide complimentary spacing charts and quote request forms to assist customers needing custom layout guidance. It is important to note that installing snow retention in isolated areas is not recommended, as this approach consistently poses a high risk of failure and potential safety hazards.

3. Ensuring Structural Integrity

When installing snow guards with mechanical fasteners, anchoring them into at least 1 inch of solid wood structure, such as plywood decking, purlins, or retrofitting blocking, is essential. For pre-engineered metal buildings, it is advisable to mount snow guards directly into metal purlins whenever possible. Relying solely on the panel as the structural support for snow guards or rails is not recommended, as it increases the risk of failure. If the structure beneath the proposed snow guard mounting points is inadequate and the ground snow load is 45 psf or less, consider using an adhesive-based product if the installer cannot easily install additional blocking.

4. Preventing Roof Leaks and Moisture Intrusion

Products like the SnoCleat PBR, SnoCleat 2.67, SnowCatchers, and screw-down rail systems come equipped with butyl tape gaskets designed to create a secure seal against the elements without needing liquid sealants. When paired with screws featuring neoprene washers, this combination ensures a watertight installation. While not mandatory, some customers apply a neutral-curing, cold-weather liquid silicone around these snow guards' edges for an additional protection layer. We recommend Novaflex MR150 sealant. When attaching any polycarbonate snow guards to the roof using screws, it is essential to utilize a neutral-curing, cold-weather liquid silicone to seal the entire base effectively.

5. Optimal Installation Timing for Adhesive-Based Systems

Screw-down snow guards and rail systems can be installed year-round, provided the roof is free of snow, ice, and debris. However, careful planning is necessary when scheduling the installation of adhesive-based snow guards. Utilizing the industry-standard adhesive SureBond SB-190 for polycarbonate snow guard installation requires approximately 28 days at 50 degrees Fahrenheit for complete curing. Late spring or early summer is typically the optimal time for installation in the USA and Canada. While temperatures below 50 degrees won't harm the adhesive, they will temporarily halt the curing process until the temperature rises.

6. Understanding Ground Snow Load Requirements

The ground snow load aids in determining your project's appropriate snow retention system requirements. This data is calculated based on historical records collected from weather stations nationwide. For projects experiencing ground snow loads of up to 45 PSF, consider glue-down and screw-down individual snow guards or screw-down snow rail systems. We recommend installing snow rail systems only in regions where ground snow loads exceed this threshold. You can typically access information regarding ground snow loads for your project through an online search or by reviewing the building plans.

Conclusion

SnoBlox-Snojax is committed to delivering an exceptional experience as you navigate, choose, and install snow guards. Our knowledgeable support team is readily available to assist you with any questions or concerns, whether you email us at support@snojax.com or by calling our toll-free number, 1-800-766-5291. We have curated valuable resources to empower our customers and facilitate informed decision-making, including a comprehensive Snow Guard Buyer's Guide and an insightful "What Works and Doesn't" page. These resources provide in-depth information, practical insights, and recommendations based on real-world experiences, ensuring you have the knowledge to make informed decisions and achieve a smooth installation process.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.