Snow Guards For Exposed Fastener Metal Roof Panels by Custom-Bilt Metals

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 24th 2024

See the Snow Guards Compatibility Chart for Custom-Bilt Metals Screw Down Metal Roofing.

"What Are the Best Snow Guards for Metal Roofs?"

Protecting buildings with exposed fastener metal roofs from winter's wrath is essential. These structures demand robust snow retention systems to combat the dangers of avalanching snow and ice. This comprehensive guide delves into an array of snow guard options designed explicitly for Custom-Bilt Metals' exposed fastener roofing, helping you pinpoint the ideal solution for your unique roofing needs. As part of our ongoing educational blog series, we spotlight leading metal panel manufacturers and their compatible snow retention systems. We aim to equip you with the knowledge to make informed choices that protect your investment and ensure safety during the harshest winter conditions. You can significantly reduce the risks of sliding snow and ice by implementing suitable snow retention measures. This proactive approach safeguards property, building occupants, and passersby from potential harm. We'll guide you through critical considerations such as roof pitch, snow load, and environmental factors to help you select the most effective system.

Exposed Fastener Metal Roof Panels by Custom-Bilt Metals

Custom-Bilt Metals, a prominent player in the metal roofing industry, traces its roots back to 1974 when Tony Chiovare established the company to serve the seamless gutter market in Southern California. The firm has undergone significant growth and transformation from these humble beginnings over the decades. Initially focused on a specific region and product, Custom-Bilt Metals gradually broadened its horizons geographically and in terms of its offerings. The company's reach expanded to encompass much of the western United States, including Alaska and Hawaii, as well as a substantial portion of the Midwest. Additionally, Custom-Bilt Metals ventured into international markets, further solidifying its presence in the industry. As the company evolved, it diversified its product line, introducing standing seam roofing with innovative on-site roll-forming technology. In 1990, the firm expanded its portfolio by incorporating metal shingles and shake products in various profiles and shapes. A significant milestone came in 2004 when Custom-Bilt Metals celebrated its 30th anniversary. This period saw the relocation of its headquarters to Chino, California, and the establishment of a large processing facility in Kent, Washington. The company also forged a strategic partnership with Vail Metals Systems, enhancing its product range and market presence. Custom-Bilt Metals has maintained a steadfast commitment to quality, customer service, and contractor support throughout its history. The company has consistently invested in specialized services and training programs to ensure its products' proper installation and use. As of 2024, Custom-Bilt Metals continues to thrive, boasting an estimated annual revenue of $35 million. Under the ongoing leadership of its founder, the company remains dedicated to innovation and growth in the metal roofing sector, continually adapting to meet the market's evolving needs.

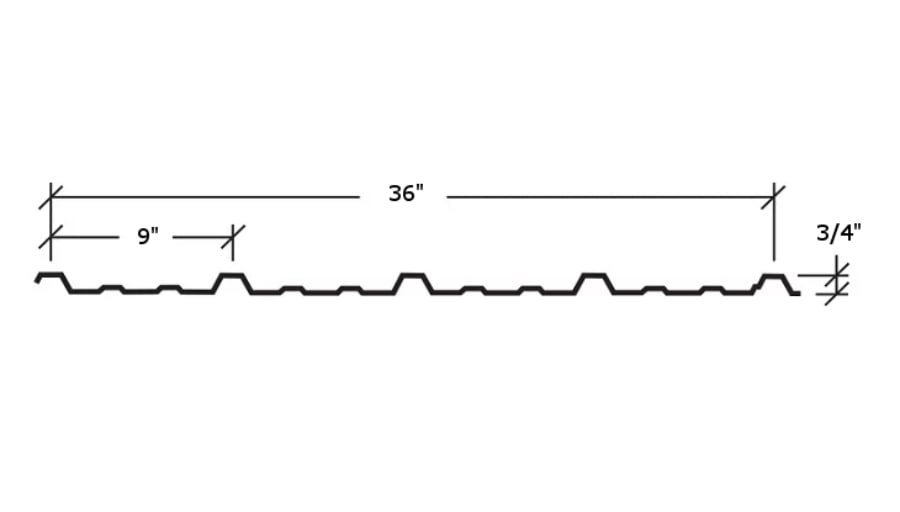

TFR-36 Panel

The TFR-36 panel offers a versatile roofing and wall cladding solution in commercial, industrial, and agricultural settings. This cost-effective option provides a generous 36-inch coverage, streamlining the installation process. The panel's design incorporates an innovative anti-siphon groove, enhancing its water-resistant properties. Manufactured using 25% recycled steel, the TFR-36 aligns with LEED criteria and is fully recyclable, underscoring Custom-Bilt Metals' commitment to sustainability. The TFR-36 features rib spacing of 9 inches on-center, which is .75" high and consistent with industry standards for similar panels. Customers can choose from 24, 26, and 29-gauge options, allowing for flexibility in strength and weight requirements for different projects. Compatible with Custom-Bilt Metals' ULTRA-Cool® technology, the TFR-36 panel can contribute to improved energy efficiency in buildings. The manufacturer offers matching trim packages, flat stock, and polycarbonate skylights to complement the panel, enabling comprehensive and cohesive installations. The TFR-36 exemplifies Custom-Bilt Metals' dedication to balancing functionality, longevity, and environmental considerations. Its features make it a practical and adaptable choice for large-scale construction projects, from warehouses to agricultural facilities. As with any building material, it's advisable to consult with Custom-Bilt Metals for the most up-to-date specifications and options for the TFR-36 panel. See the Snow Guards Compatibility Chart for Custom-Bilt Metals TFR-36 Screw Down Metal Roofing.

The TFR-36 Panel offers versatile snow retention options, allowing users to choose between adhesive or screw-based installation methods. The polycarbonate SnoBlox Deuce and SnowBreaker are compatible with glue-down and screw-down attachment techniques and can be mounted centrally between the minor ribs. For those preferring metal snow guards secured with screws in the panel's center flat, the SnoCleat PBR and all six SnowCatcher shapes are suitable alternatives. Additionally, the Snojax I and Icejax I can be utilized by straddling one of the minor ribs between each 9-inch rib. While the Icejax I accommodates both adhesive and screw installation, the Snojax I requires mechanical fastening and is not suitable for adhesive application. The TFR-36 Panel can be paired with Tall ColorBrackets and mechanical fasteners, making it compatible with aluminum ColorBar PBR and galvanized SnoBar PBR snow rail systems. This combination provides a comprehensive solution for effective snow retention and management.

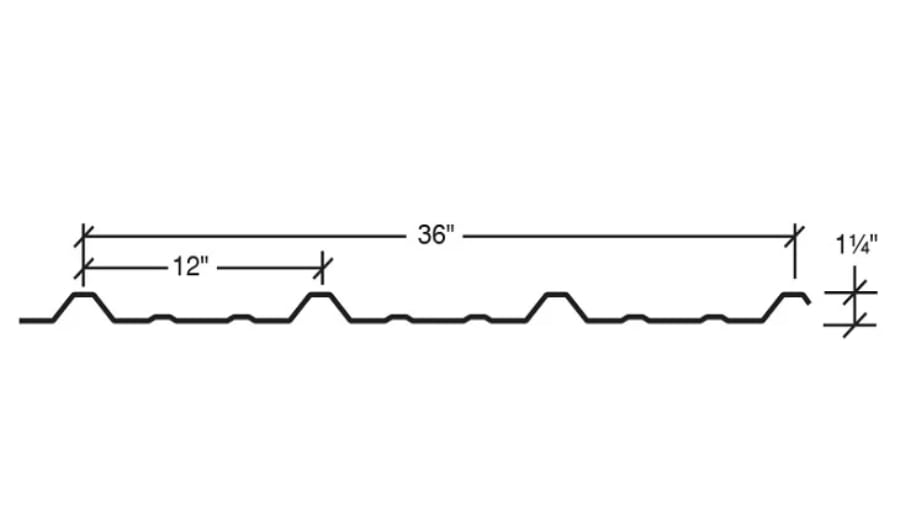

PBR Panel

Custom-Bilt Metals offers a versatile, cost-effective roofing solution with their PBR metal roof panel. This product is well-suited for various applications, including commercial, industrial, and agricultural buildings. This panel features a 36-inch coverage width with major ribs on 12" spacing and a 1-1/4 inch rib height. The PBR panel's design allows for direct installation over purlins or joists using exposed fasteners, making it a through-fastened system that can be mounted vertically or horizontally to accommodate various architectural needs. The company provides these panels in different materials and finishes, such as Bare Zincalume®, natural copper, and weathering steel. The panels are coated with high-performance 70% PVDF pigments to enhance durability and energy efficiency. These pigments are known for their superior heat reflection and fade resistance. This coating is available under brand names like Kynar 500®, Hylar® 5000, or Fluropon®. Custom-Bilt Metals' PBR panels feature 25% recycled steel content that aligns with sustainable building practices. They are fully recyclable and meet LEED criteria. The company also offers complementary products such as trim packages, matching flat stock, and compatible polycarbonate skylights to ensure a complete roofing system. See the Snow Guards Compatibility Chart for Custom-Bilt Metals PBR Screw Down Metal Roofing.

The PBR panel system is super flexible when installing snow guards. It works with all kinds of preferences and project needs. These panels work with various snow guard models. The screw-down SnoBar and ColorBar snow rail systems, the SnoCleat PBR, and the stainless steel SnowCatchers, including cool designs like the Standard Rectangle, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak, are some of the options that work. Most polycarbonate snow guard models, except for the Snojax I, can be attached to these panels using glue or screws. The Snojax I is the odd one out and can only be installed with screws. When using polycarbonate models, you need to use the Surebond SB-190 adhesive. It's the industry standard for these materials. This glue doesn't work for metal pad-style snow guards. For best results, mount smaller snow guards between the minor ribs in the center of the panels. Some models, like the Snojax II and Icejax II, must be mounted off-center, straddling either the left or right minor rib. Make sure to put them in the same spot over the same rib. Don't ever screw the snow guards or rail systems right onto the high ribs of the panel. Instead, screw them through the low flat parts of the panel into a solid structure underneath, making them super strong and stable. For more information on why this is important, check out our blog, "Mounting Snow Guards on the High Ribs or the Panel Flats: Which is Correct?".

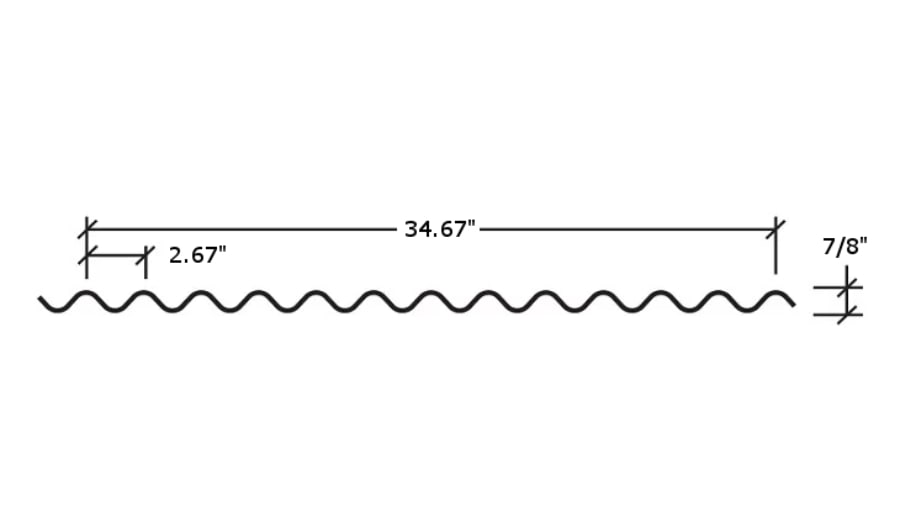

Corrugated Panel (Standard Wavy)

Custom-Bilt Metals produces a range of corrugated metal panels suitable for roofing and wall applications. These panels add a unique architectural element to buildings, providing durability and functionality. The company offers two main profile options: a traditional corrugated style with 7/8-inch ridges and a wider 7.2-inch ribbed variant. Customers can choose from several material options, including Zincalume®, copper, and weathering steel, offering distinct aesthetic and performance characteristics. One of the standout features of Custom-Bilt Metals' corrugated panels is their advanced coating technology. The panels are treated with high-performance PVDF coatings, incorporating reflective pigments to enhance energy efficiency. These coatings, available under brand names like Kynar 500®, Hylar® 5000, and Fluropon®, also provide excellent resistance to fading, ensuring the panels maintain their appearance over time. Environmental consciousness is evident in the product's composition, with the panels containing 25% recycled steel and being fully recyclable at the end of their life cycle. This eco-friendly aspect, combined with their energy-reflecting properties, makes them a good fit for projects aiming for LEED certification. The panels are precision-manufactured in factory settings, ensuring consistent quality and performance across installations. Whether used in residential, commercial, or industrial contexts, Custom-Bilt Metals' corrugated panels offer a blend of visual appeal, longevity, and sustainable features, making them an attractive option for modern construction and renovation projects. See the Snow Guards Compatibility Chart for Custom-Bilt Metals Corrugated Panel (Standard Wavy) Screw Down Metal Roofing.

The 7/8" Corrugated Panel boasts a distinctive wavy corrugated profile that differentiates it from conventional exposed fastener roofing systems. This unique design enables the installation of snow guards on the elevated ribs of the panel, an exception to typical roofing guidelines. Customers seeking snow retention solutions will find the 7/8" Corrugated Panel compatible with various options. The recently introduced SnoCleat 2.67 snow guards can be securely attached to the elevated ribs of the panel using 3-inch screws. Alternatively, customers may opt for the SnoBar or ColorBar snow retention systems, which utilize the same ColorBracket 2.67 as the SnoCleat 2.67. Each ColorBracket 2.67 has six attachment holes, allowing for enhanced mounting strength. While only four screws per bracket are necessary, customers have the flexibility to use all six screws, particularly in regions prone to more extreme weather conditions, ensuring a robust and reliable installation.

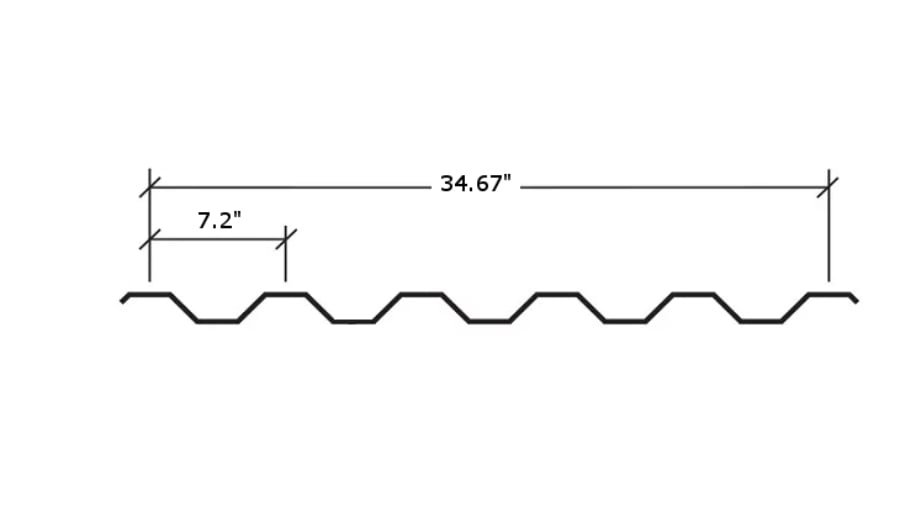

Corrugated Panel (7.2 Variant)

Custom-Bilt Metals, a leading manufacturer, offers a diverse range of corrugated metal panels for roofing and wall applications. These panels enhance the architectural aesthetics of buildings while providing unparalleled durability and functionality. The company's product line features two main profile options: a traditional corrugated style with 7/8-inch ridges and a wider 7.2-inch ribbed variant, allowing customers to choose the perfect fit for their project. Customers can select from premium materials, including Zincalume®, copper, and weathering steel, offering unique aesthetic qualities and performance characteristics. One of the most notable features of Custom-Bilt Metals' corrugated panels is their advanced coating technology. These panels are treated with high-performance PVDF coatings, such as Kynar 500®, Hylar® 5000, and Fluropon®, incorporating reflective pigments to enhance energy efficiency. These coatings also provide exceptional resistance to fading, ensuring the panels maintain their vibrant appearance for years. Custom-Bilt Metals is committed to environmental sustainability by incorporating 25% recycled steel into their panels and ensuring they are fully recyclable at the end of their life cycle. This eco-friendly aspect, combined with their energy-reflecting properties, makes them an ideal choice for projects aiming to achieve LEED certification. The panels are precision-manufactured in state-of-the-art factory settings, ensuring consistent quality and performance across all installations. Whether used in residential, commercial, or industrial contexts, Custom-Bilt Metals' corrugated panels offer a perfect blend of visual appeal, longevity, and sustainable features, making them a top choice for modern construction and renovation projects. See the Snow Guards Compatibility Chart for Custom-Bilt Metals Corrugated Panel (Standard Wavy) Screw Down Metal Roofing.

To effectively manage snow and ice accumulation on your roof, the 7.2 Panel integrates with several snow control systems. The polycarbonate SnoBlox Deuce is a transparent, pad-style guard, allowing you to retain snow and ice on the roof surface. The SnowBreaker and SnowBreaker 3M, on the other hand, break down the accumulated snow and ice into more manageable and safer pieces as they shed them from the roof. Installers can secure these snow guards using screws or adhesive. At the same time, the SnowBreaker 3M offers the convenience of 3M double-sided tape for attachment. The 7.2 Panel is also compatible with the galvanized SnoBar and aluminum ColorBar snow rail systems. Both systems employ the sturdy 1.5-inch wide aluminum Tall ColorBracket for secure attachment, effectively managing snow on your roof.

Custom-Bilt Metals Compatibility Chart for Snow Guards

| TFR-36 Profile | PBR Profile | Corrugated Profile | 7.2 Variant Profile | |

|---|---|---|---|---|

| IceJax I Screw Down | YES | YES | NO | NO |

| IceJax I Glue Down | YES | YES | NO | NO |

| IceJax II Screw Down | NO | YES | NO | NO |

| IceJax II Glue Down | NO | YES | NO | NO |

| SnoBlox Deuce Screw Down | YES | YES | NO | YES |

| SnoBlox Deuce Glue Down | YES | YES | NO | YES |

| SnoBlox Ace Screw Down | NO | YES | NO | NO |

| SnoBlox Ace Glue Down | NO | YES | NO | NO |

| Snojax I Screw Down | YES | YES | NO | NO |

| Snojax II Screw Down | NO | YES | NO | NO |

| Snojax II Glue Down | NO | YES | NO | NO |

| SnowBreaker 3M | YES | YES | NO | YES |

| SnowBreaker Screw Down | YES | YES | NO | YES |

| SnowBreaker Glue Down | YES | YES | NO | YES |

| SnowCatcher | YES | YES | NO | NO |

| Decorative SnowCatcher | YES | YES | NO | NO |

| SnoCleat PBR | YES | YES | NO | NO |

| SnoCleat 2.67 | NO | NO | YES | NO |

| SnoBar PBR | YES | YES | NO | YES |

| ColorBar PBR | YES | YES | NO | YES |

| SnoBar 2.67 | NO | NO | YES | NO |

| ColorBar 2.67 | NO | NO | YES | NO |

Considerations for Purchasing and Installing Snow Guards for Custom-Bilt Metals Exposed Fastener Metal Roofing

Making Sure Your Snow Guard Installation Is Rock Solid

When installing mechanically mounted snow guards, anchor them into something sturdy. Aim for at least an inch of solid wood, like plywood decking or purlins. For metal buildings, try to attach them right to the metal purlins. Don't just rely on the roof panel—that's asking for trouble. Suppose the structure underneath is flimsy, and your snow load is manageable. In that case, you should go for adhesive products if adding extra support is impossible.

Figuring Out How Much Snow You're Dealing With

You must know how much snow your roof might handle to pick the proper snow guards. Weather experts use historical data to figure this out. This number is known as your ground snow load. If you're in an area with 45 PSF or less snow, you can use individual snow guards or screw-down rails. For heavier snow, stick to rail systems. You can find your local snow load online, in your building plans, or by asking your local officials.

Planning Where to Put Your Snow Guards

No matter what type of snow guards you choose to install, it's a good idea to get some advice from the manufacturer on how to lay them out. We offer free spacing guides and custom quote request forms for customers needing a custom plan. Remember, don't install snow guards in only isolated areas - that's a recipe for disaster. Snow guards installed in this manner tend to overload.

Matching Your Roof's Color

Want your snow guards to blend in with your roof? No problem. You can get color strips that slide into the faces of our ColorBar systems and SnoCleat snow guards, or you can have our metal snow guards powder-coated to match your roof. Powder-coating has a longer lead time, as we do not keep coated guards in stock, but you can also get them coated locally or paint them yourself if you're in a hurry.

When to Install Glue-Down Snow Guards

While you can install screw-down snow guards or snow rail systems almost anytime, adhesive ones need some planning. Our recommended adhesive, Surebond SB190, requires about a month of warm weather to cure fully. Late spring or early summer is your best bet in the US and Canada. Colder temperatures won't hurt the adhesive but will pause the curing process until it warms up again.

Keeping Your Roof Leak-Free

Our metal snow guards and mounting brackets for snow rail systems come with butyl tape that keeps water out, so you don't need to use sealants. Our screws come equipped with neoprene rubber washers too, which helps. Some customers like adding NoveFlex MR150 sealant around the edges for extra protection, but this is unnecessary. If you're using our polycarbonate snow guards with screws, you need to use silicone to seal them properly. Cover the entire base before pressing down on the roof to ensure no air bubbles are present beneath the guard's base.

Conclusion

At SnoBlox-Snojax, we're dedicated to ensuring your snow guard installation is a straightforward, rewarding process. Our expert team stands ready to assist you with your questions every step of the way. We're just a call or email away. Contact us at support@snojax.com or dial our customer support line at 1-800-766-5291. We've developed comprehensive resources to empower you with knowledge and confidence. Our Snow Guard Buyer's Guide is invaluable, offering detailed information to help you easily navigate the selection process. For practical insights, our "What Works and Doesn't" page highlights effective strategies and common pitfalls to avoid, setting you up for installation success. We encourage you to take full advantage of these resources, which will equip you with the expertise to make informed decisions about our snow guard solutions. SnoBlox-Snojax is committed to providing you with top-quality products and the knowledge to use them effectively, ensuring an exceptional experience with us.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.