Snow Guards For Schulte Building Systems Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Sep 13th 2024

See the Snow Guards Compatibility Chart for Schulte Building Systems (SBS) Screw Down Metal Roofing Panels.

Do I Need Snow Guards on Schulte Building Systems (SBS) Screw Down Metal Panels?

Metal roofs, especially those with exposed fastener designs, present notable challenges during winter months. The primary issue is the potential for sudden snow and ice slides, which can endanger people, pets, and property below.

The smooth surface of metal roofs increases the likelihood of snow avalanches, amplifying this risk. Effective snow retention systems are crucial for ensuring safety and addressing this concern. Snow guards have emerged as a specialized solution to this problem, offering compatibility with various metal roof designs. When choosing a snow retention system, it's essential to consider several factors, including the roof's slope, panel design, and local weather conditions. Various educational resources are available to assist building owners, homeowners, and facility managers in making well-informed decisions. These include our informative blogs, dedicated resource web pages, and database listing compatible products for our products with different metal panel manufacturers. The goal of emphasizing education and innovative solutions is to reduce the risks associated with snow and ice slides. This approach aims to create safer environments in areas prone to heavy snowfall, enabling customers to enjoy the advantages of metal roofing without compromising safety during harsh winter conditions.

Exposed Fastener Metal Roof Panels by Schulte Building Systems

Schulte Building Systems (SBS) has emerged as a leading force in the metal building industry since its inception. Founded by Johnie Schulte, the company has experienced significant growth, evolving from its modest beginnings to become a major player known for delivering high-quality, custom-engineered building solutions. SBS's journey began with establishing a state-of-the-art manufacturing facility in Hockley, Texas, the foundation for its future expansion. In 2006, SBS expanded its operations by opening a second manufacturing plant in Hueytown, Alabama, further enhancing its production capabilities. A pivotal moment in the company's history came in 2008 when it acquired Inland Building Systems in Cullman, Alabama, solidifying its position in the metal building market. This strategic move set the stage for remarkable growth in the following years. SBS reached a significant milestone in 2011, surpassing $100 million in sales. The company's commitment to innovation and customer satisfaction has driven its continued success, with annual sales averaging around $400 million. Throughout its growth, SBS has maintained a strong focus on reliability, durability, and meeting customer needs. The company's product portfolio encompasses a wide range of metal building solutions, with its standing seam roof systems being particularly well-regarded in the industry. With multiple manufacturing facilities strategically located across the United States, SBS is well-positioned to serve the diverse needs of architects, builders, contractors, and erectors throughout the Midwest and Southeast regions.

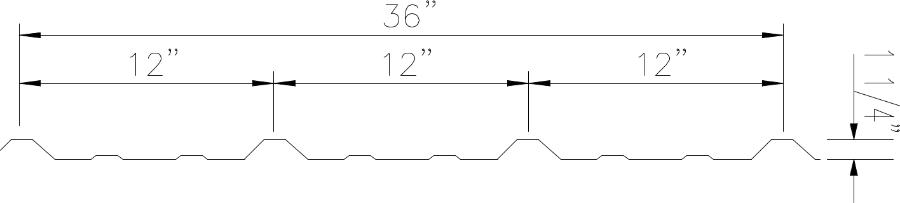

PBR

The PBR panel is a versatile metal building component designed for roofing, walls, liner, mansard, and soffit applications in various structures, including commercial, industrial, and agricultural buildings. Characterized by its 36-inch coverage width, this panel allows for efficient installation, potentially reducing project time and labor costs. The panel features major ribs that are 1-¼" deep and spaced 12" apart, creating an even shadowed appearance. Between these major ribs, two minor ribs provide additional strength and stability. This design enhances the panel's structural integrity and facilitates effective water shedding. Known for durability and weather resistance, the PBR panel meets or exceeds industry standards, offering excellent load-bearing capacity and wind resistance. Its wide coverage contributes to a streamlined appearance and reduces the number of seams, improving weather-tightness and energy efficiency. Compatible with various insulation systems and other building components, this panel is popular for new construction and retrofit projects across different building types. See the Snow Guards Compatibility Chart for Schulte Building Systems (SBS) PBR Screw Down Metal Roofing Panels.

The PBR panel system offers a comprehensive and adaptable solution for snow guard installation, catering to a wide range of models and designs. This versatile system accommodates various needs, including screw-down options like SnoBar and ColorBar rail systems and specialized alternatives such as SnoCleat PBR and different stainless steel SnowCatcher designs. Install most polycarbonate snow guards using either screws or adhesives and for the best results, use Surebond SB-190 adhesive because of its excellent bonding properties. However, it's important to note that this particular glue is unsuitable for metal pad-style guards. Proper placement is essential for optimal performance, and specific guidelines exist for different models. Installers should avoid attaching snow guards directly to the panel's high ribs to ensure maximum stability and strength. Instead, securing the snow guards through the panel's low flats into a solid underlying structure is the most effective method. This approach guarantees a robust and reliable snow retention system that withstands harsh winter conditions. Following these guidelines, installers can create a snow guard system that protects against potential hazards associated with snow and ice accumulation on roofs.

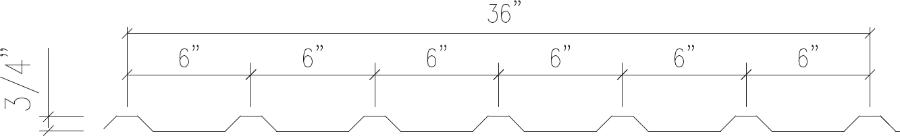

PBU

Schulte Building Systems offers a versatile panel called the PBU with 36-inch coverage. This panel features shallow ribs that are ¾ inch deep and spaced 6 inches apart. The PBU panel's design suits various building construction applications, including wall panels, liners, partitions, and soffits. As a purlin bearing leg (PBL) panel, the PBU has specific installation requirements that align with its structural design. While the exact material composition is not specified, Schulte Building Systems provides various finishing options for their panels. These include silicone polyester and high-performance fluoropolymer coatings, such as those using Kynar 500 or Hylar 5000. Customers can select from a wide array of standard colors, allowing them to balance aesthetic preferences with performance needs and budget constraints. The PBU panel is part of Schulte Building Systems' broader offering of metal panels for roofs and walls, designed to address diverse architectural and structural requirements in the construction industry. Its versatility and range of finish options make it a valuable component in Schulte's product lineup. See the Snow Guards Compatibility Chart for Schulte Building Systems (SBS) PBU Screw Down Metal Roofing Panels.

The PBU panel, with its distinctive narrow and flat areas measuring approximately 3 1/2 inches in width, presents unique challenges for implementing snow retention systems. Despite these obstacles, numerous effective options are still available for those seeking to manage snow and ice accumulation on their roofs. We recommend the Ace, Deuce, or Icejax I models for individuals prioritizing secure snow and ice retention on their rooftops. Individual polycarbonate snow guard pads excel at retaining snow on roofs. Alternatively, the SnowBreaker or SnowBreaker 3M models offer ideal solutions for those who want to control snow-shedding, releasing snow and ice in smaller, less hazardous amounts. Installation flexibility is a crucial feature of all these models, as they can be mounted using either screws or Surebond SB-190 adhesive. For those who prefer a bar-style approach to snow retention, the PBU panel is compatible with tall ColorBrackets, enabling the mechanical attachment of SnoBar and ColorBar systems.

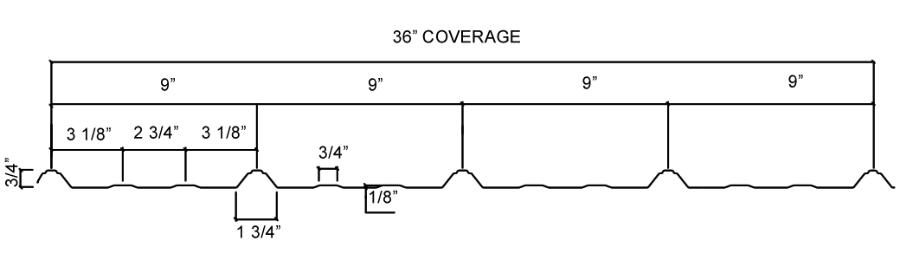

SBS-369

Schulte Building Systems offers the SBS-369, a versatile panel with a 36-inch coverage width after lapping. This panel features a ¾-inch rib depth and ribs spaced at 9-inch centers. The SBS-369 suits various construction applications, including roofing, wall cladding, and liner panels. When calculating panel requirements, it's important to note that one square equals 100 square feet, with each linear foot covering 3.167 square feet. The panel's width for calculation purposes is 38 inches before lapping. The SBS-369 is available in 29 and 26-gauge options, with several finish choices to suit different project needs. These finishes include Clear Acrylic Coating, PPOL Polar White, SMP Standard Colors, and Kynar 500® Standard Colors. The base metal used is Galvalume® with either AZ55 or AZ50 coating weight. See the Snow Guards Compatibility Chart for Schulte Building Systems (SBS) SBS-369 Screw Down Metal Roofing Panels.

The SBS-369 Panel offers a wide range of snow retention solutions to accommodate different installation preferences and material choices. For those who prefer polycarbonate options, we recommend the SnoBlox Deuce and SnowBreaker models or placement in the center of the spaces between minor ribs. Metal-based alternatives include screw-mounted products such as the SnoCleat PBR and six distinct SnowCatcher designs, best installed in the panel's central flat area. The Snojax I and Icejax I are additional options designed to span the minor ribs between 9" sections, with the Icejax I offering both adhesive and screw mounting options, while the Snojax I requires mechanical fastening. To create a more comprehensive snow management system, the SBS-369 can be paired with Tall ColorBrackets and appropriate fasteners to support either aluminum ColorBar PBR or galvanized SnoBar PBR snow rail systems. This integrated approach ensures effective and reliable snow accumulation management, providing optimal performance across various weather conditions and environmental settings.

Schulte Building Systems Compatibility Chart for Snow Guards

| PBR Profile | PBU Profile | SBS-369 Profile | |

|---|---|---|---|

| IceJax I Screw Down | YES | YES | YES |

| IceJax I Glue Down | YES | YES | YES |

| IceJax II Screw Down | YES | NO | NO |

| IceJax II Glue Down | YES | NO | NO |

| SnoBlox Deuce Screw Down | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES |

| SnoBlox Ace Screw Down | YES | YES | NO |

| SnoBlox Ace Glue Down | YES | YES | NO |

| Snojax I Screw Down | YES | NO | YES |

| Snojax II Screw Down | YES | NO | NO |

| Snojax II Glue Down | YES | NO | NO |

| SnowBreaker 3M | YES | YES | YES |

| SnowBreaker Screw Down | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES |

| SnowCatcher | YES | NO | YES |

| Decorative SnowCatcher | YES | NO | YES |

| SnoCleat PBR | YES | YES | YES |

| SnoCleat 2.67 | NO | NO | NO |

| SnoBar PBR | YES | YES | YES |

| ColorBar PBR | YES | YES | YES |

| SnoBar 2.67 | NO | NO | NO |

| ColorBar 2.67 | NO | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Schulte Building Systems

Optimal Snow Guard Positioning for Maximum Effectiveness

The strategic placement of snow guards is crucial for their proper functioning. Adhere to the recommended guidelines for the most effective configuration. Avoid concentrating guards in specific isolated areas, such as directly above entryways or paths, as this can overburden the system and cause it to fail. Our website provides valuable resources, including spacing guides and quote request forms.

Coordinating Snow Guards with Roof Aesthetics

Snow guards should complement your roof's color palette to achieve a unified look. For ColorBar and SnoCleat systems, you can order custom color strip inserts or repurpose leftover roofing materials to create your own. Metal pad-style guards and rail systems can be powder-coated for an exact match. Consider local coating services or DIY painting for quicker solutions, but powder coating may require more time.

Evaluating Your Roof's Snow-Bearing Capacity

Understanding your roof's snow load capacity is vital when choosing the appropriate snow retention system. Meteorologists use historical data to determine regional ground snow loads. Individual guards or screw-down rails are typically sufficient in areas with 45 PSF or less ground snow loads. However, we recommend rail systems for regions with heavier snowfall.

Ideal Timing for Adhesive Snow Guard Installation

The installation timing for adhesive snow guards is critical. In North America, late spring or early summer is optimal. The adhesive, Surebond SB190, needs approximately one month of temperatures above 50°F (10°C) to cure completely. While cold weather can impede curing, rain is not problematic after 24 hours.

Ensuring Water Resistance for Snow Guards

Proper silicone sealant application is essential for screw-mounted polycarbonate snow guards. Cover the base and press down firmly to remove any trapped air. While metal snow guards and rail brackets come with waterproof gaskets, some installers add sealant around the edges for additional protection, though this is not required.

Proper Attachment of Snow Guards

Securely fastening snow guards is crucial for mechanically mounted roofs. They should be attached to a solid substrate, preferably with at least one inch of durable wood, such as plywood decking or purlins. For metal structures, connecting directly to metal purlins is the best practice. Avoid relying solely on the roof panel for support. If additional reinforcement isn't possible, consider using adhesive-mounted guards for less robust roofs.

Conclusion

SnoBlox-Snojax is a leading provider of snow guard solutions, offering a wide array of products and specialized support for optimal installations. Our dedicated team provides personalized guidance through various channels, ensuring customers receive expert assistance throughout the installation. SnoBlox-Snojax has developed comprehensive resources to empower clients, including a detailed Snow Guard Buyer's Guide and an informative page on effective snow guard practices. These tools provide valuable insights and practical information, helping customers make informed decisions. SnoBlox-Snojax equips clients with the necessary knowledge and resources for successful snow guard implementations by extending our commitment to quality beyond products and into customer education. This approach fosters a deeper understanding of our offerings and enhances customer satisfaction.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.