Snow Guards For Standing Seam Metal Roof Panels by Berridge

Posted by Derek Gamble - SnoBlox-Snojax Specialist on May 22nd 2024

See the Snow Guards Compatibility Chart for Berridge Manufacturing Standing Seam Metal Roofing Panels.

It's essential to be proactive when installing snow guards and snow retention systems on "concealed fastener" or "standing seam" metal roofs. If you don't, your property could be at risk from sliding snow and ice. The unique designs of different metal roof panels often require specialized snow guard solutions to deal with these winter weather challenges effectively. This practical guide shows you a range of snow guard options that work with Berridge's standing seam metal panels, giving you the knowledge to make an informed decision for your roof system's needs. As part of an ongoing series, these blogs will highlight top metal panel manufacturers and recommend compatible snow guard solutions. The goal is to give you the confidence and expertise to smoothly navigate this process, allowing you to make well-informed choices that protect your investment and keep your property and its occupants safe. We provide detailed information to help you select the most appropriate snow guard system. This guidance ensures optimal protection and peace of mind during the harsh winter.

Standing Seam Metal Roof Panels by Berridge

Berridge Manufacturing Company got its start in 1970. Jack Berridge, who had a knack for architectural metal panels, founded it. In the early days, the company made metal panels and shingles mainly for architects and their projects. Things took an innovative turn in 1986 when Berridge introduced the first portable roll-former to create curved and straight standing seam panels right on the job site, giving contractors much more flexibility. Jack Berridge also patented products like the Vinyl Weatherseal and the Berridge Tee-Panel standing seam roofing system back in 1971. The 1990s were a growth spurt for Berridge; they built new facilities and opened branch plants nationwide. By 1999, they had over 150 employees and 300,000 square feet of plant and office space. That year, the company's founder, Jack Berridge, retired after establishing Berridge as a significant player through new designs and quality products. These days, Berridge manufactures its portable roll-forming machines, which it either leases or sells to nearly 300 licensed contractors nationwide. The company provides top-notch factory equipment and a full line of architectural metal roofing and siding products, keeping up its tradition of innovation in the industry.

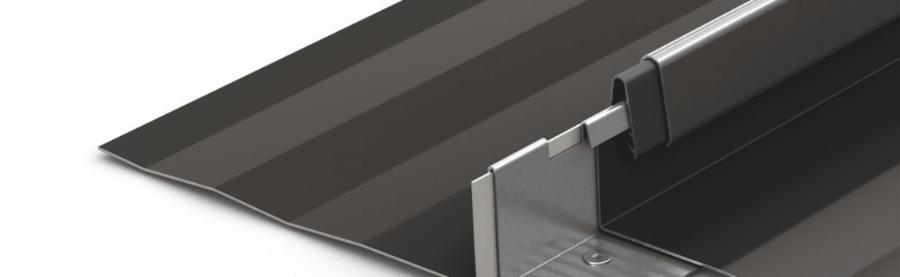

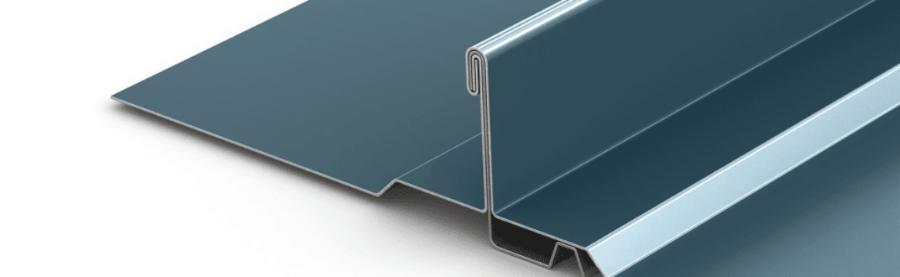

Tee-Panel

The Tee-Panel is a standing seam metal roofing system that combines durability, versatility, and aesthetic appeal. This system features a 1-inch high snap-on batten seam with an integrated extruded vinyl weather seal, ensuring superior protection against water infiltration and siphoning. Available primarily in 24-gauge steel, with limited options for 22-gauge steel or 0.032 aluminum, the Tee-Panel features a smooth finish and concealed fasteners, contributing to its sleek and modern appearance. With a coverage width of 12-3/4", these panels can be obtained in continuous lengths up to 40 feet from the factory or roll-formed on-site, accommodating various project requirements. One of the standout features of the Tee-Panel is its suitability for curved and tapered applications, allowing architects and builders to explore creative designs. The system offers an extensive range of color options, including standard, metallic, premium, and custom hues, ensuring a perfect match for any aesthetic preference. Berridge's Tee-Panel has undergone rigorous testing and certification processes, earning UL ratings for wind, fire, and impact resistance. Additionally, it has been evaluated according to ASTM standards, demonstrating its ability to withstand harsh weather conditions and ensure long-lasting performance. The installation involves using Berridge's proprietary Tee-Clips for secure attachment to the substrate, with stainless steel clips employed for aluminum panels. An approved underlayment is required over the entire roof area, enhancing the system's weather resistance and longevity. See the Snow Guards Compatibility Chart for Berridge Manufacturing Tee-Panel Standing Seam Metal Roofing Panels.

These metal roofing panels accommodate various snow retention solutions, providing an excellent surface for adhering polycarbonate snow guards. Proper adhesive application of polycarbonate snow guards is crucial to prevent moisture intrusion and subsequent issues like refreezing, which can lead to detachment. Customers can choose from a range of snow guard options, including larger solutions like the IceJax II, Snojax II, and SnoBlox Ace, as well as smaller alternatives such as the SnoBlox Deuce and IceJax I, effectively retaining snow and ice on their roofs. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable chunks. Due to the combination of this panel's metal batten strip cover and the vinyl Weatherseal featured inside the seams of this panel, clamp-on snow guards and snow rail systems are incompatible. When attempting to clamp over this seal, you cannot achieve a proper torque setting to ensure a secure attachment like you would with direct metal-on-metal crimping. Pad-style snow guards are generally unsuitable for curved roofs as they necessitate a completely flat surface for proper installation. In such scenarios, snow rail systems are the appropriate solution. Suppose a clamp-on snow rail is incompatible with the curved panel's seams. In that case, it is advisable to consult the roofing manufacturer for their recommended snow retention methods. When installing clamp-on snow rails on aluminum roof panels, which are typically softer than roof panels made from steel, it may be necessary to install additional rows to account for the difference in panel strength.

Curved or Tapered Tee-Panel

The Curved or Tapered Tee-Panel is essentially the same panel as the standard Tee-Panel, with the same 1" high ribs and 12-3/4" coverage width. It also comes in the same 24-gauge steel, with limited options for 22-gauge steel or 0.032 aluminum. What sets the Curved or Tapered Tee-Panel apart is its ability to be curved or tapered on-site, allowing for convex curves with a minimum radius of 4 feet, concave curves with a minimum radius of 6 feet, and compound curved tee-panels. Berridge's SL-1 Roll Former forms the compound curved Tee-Panels on-site. At the same time, workers must hand-curve the panels over solid decking for other curve types. The Berridge SS-14 or SC Roll Former can also curve the snap-on seams, with the factory forming extra seam caps up to 40 feet long to ensure a seamless and visually appealing finish. See the Snow Guards Compatibility Chart for Berridge Manufacturing Curved or Tapered Tee-Panel Standing Seam Metal Roofing.

This roofing system meets various testing standards, including UL fire resistance, impact resistance, water penetration, and air leakage ratings, ensuring its reliability and performance. With its unique design and versatility, the Curved or Tapered Tee-Panel by Berridge allows architects and builders to create distinctive architectural roofing and fascia applications that demand curved or tapered profiles while providing superior weather protection and durability.

We do not recommend pad-style snow guards for these panels because they are designed exclusively for installation on curved, radiused roofs, and pad-style snow guards require a perfectly flat surface for correct installation. In these cases, snow rail systems are typically the appropriate choice. However, the metal batten strips containing the vinyl weather seal within the seams of this panel prevent the use of clamp-on snow guards and snow rail systems. When installed over this seam style, these systems will fail to achieve the torque setting for a secure attachment, unlike the typical metal-on-metal crimping method. Should a clamp-on snow rail be incompatible with the curved panel's seams, as it is in this case, it is best to seek the roofing manufacturer's recommendations for snow retention. Aluminum roof panels, being softer than their steel counterparts, may require additional rows of clamp-on snow rails to account for the difference in panel sturdiness.

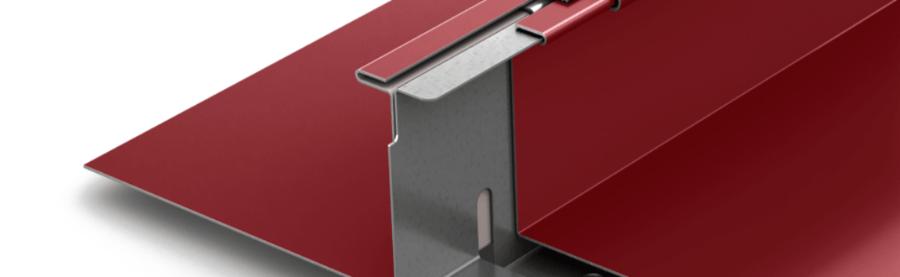

High Seam Tee-Panel

The High Seam Tee-Panel is a premium roofing product that combines visual appeal and exceptional performance. Crafted from high-quality 24- and 22-gauge steel or 0.032 aluminum, this panel features a distinctive tall seam profile, ranging from one inch to one-and-a-half inches in height. This elevated seam design adds a striking aesthetic and expands the range of finish options, catering to diverse architectural preferences. With a generous coverage width of 18-1/4" and concealed fasteners, the High Seam Tee-Panel presents a sleek and contemporary appearance. Customers can choose between a striated finish, which adds texture and depth, or a smooth finish for a more understated look. The panel's versatility extends to curved designs, allowing architects and builders to create visually stunning and seamless curved rooflines. Designed with durability in mind, the High Seam Tee-Panel features an extruded vinyl weather seal integrated into the snap-on seam cap. This innovative feature effectively prevents water infiltration and siphoning, ensuring long-lasting protection against the elements. Whether used for high-end residential roofs with sweeping curves or commercial fascias with a sleek, striated finish, this panel delivers style and substance. Rigorous testing and certifications back the High Seam Tee-Panel, which meets stringent industry standards for wind, fire, and impact resistance. It has undergone comprehensive ASTM testing for wind and water resistance, providing peace of mind and ensuring a reliable and durable roofing solution for years. See the Snow Guards Compatibility Chart for Berridge Manufacturing High Seam Tee-Panel Standing Seam Metal Roofing.

These metal roofing panels, compatible with various snow retention systems, provide an excellent surface for adhering polycarbonate snow guards. Proper adhesive application is crucial to prevent moisture intrusion and potential issues like refreezing, which can lead to detachment. Customers can choose from a range of options, including larger solutions like the IceJax II, Snojax II, and SnoBlox Ace, as well as smaller alternatives such as the SnoBlox Deuce and IceJax I, effectively retaining snow and ice on their roofs. The SnowBreaker and SnowBreaker 3M products aid in safer snow and ice shedding by breaking the snowpack into smaller, more manageable pieces. When using glue-down polycarbonate snow guards with this panel, a thicker application of Surebond SB-190 adhesive may be necessary to compensate for the panel's striations, ensuring a secure and reliable installation. Due to the metal seam cap and vinyl Weatherseal featured inside the seams of this panel, clamp-on snow guards and snow rail systems are incompatible. If installed over this cap and seal, these systems prevent proper torque settings for secure attachment, unlike typical metal-on-metal crimping. Pad-style snow guards are generally unsuitable for curved roofs as they require a completely flat surface for proper installation. In such scenarios, snow rail systems are the appropriate solution. Suppose a clamp-on snow rail is incompatible with the curved panel's seams. In that case, it is advisable to consult the roofing manufacturer for their recommended snow retention methods. Since aluminum roof panels are typically less robust than steel panels, the installation of clamp-on snow rails might require the addition of supplementary rows to accommodate the disparity in panel strength.

Curved or Tapered High Seam Tee-Panel

The Curved or Tapered High Seam Tee-Panel is another version of the same design featured on the standard High Seam Tee-Panel. Berridge manufactures it from the same durable 24- and 22-gauge steel or 0.032 aluminum. It offers the same wide 18-1/4" coverage and features prominent high seams that create a distinctive visual impact. It is available in striated and optional smooth finishes, catering to different aesthetic preferences. The snap-on seam incorporates an integral extruded vinyl weather seal, ensuring long-lasting durability and effective weather resistance. The High Seam Tee-Panel, formed on-site using the Berridge SS-1421 Roll Former, allows straight and curved applications. For a one-inch seam, the minimum radius of curvature allowed for a convex (outward) curve is 5 feet. In comparison, the minimum concave (inward) curve is 8 feet. These curvature minimums prevent excessive stress or deformation on the seam. The one-and-one-half-inch seam is convex at a minimum of 8 feet, while concave applications are not available for this seam height. The Berridge SL-24 Roll Former can form straight tapered panels on-site but cannot curve them. This versatility in forming and shaping makes the Curved or Tapered High Seam Tee-Panel ideal for creating modern rooftop designs or achieving unique tapered or curved aesthetics in commercial spaces, combining style and durability with its extruded vinyl weather seal. See the Snow Guards Compatibility Chart for Berridge Manufacturing Curved or Tapered High Seam Tee-Panel Standing Seam Metal Roofing.

Pad-style snow guards are not recommended on these panels as they are designed exclusively for installation on curved radiused roofs. These snow guards require a perfectly flat surface for proper installation. In such cases, snow rail systems are typically the appropriate choice. However, the vinyl Weatherseal and metal seam cap prevent clamp-on snow guards and snow rail systems. Unlike the typical metal-on-metal crimping method, these systems fail to achieve the proper torque setting for a secure attachment when installed over the seal and cap. If a clamp-on snow rail is incompatible with the curved panel's seams, as it is in this case, it is advisable to seek the roofing manufacturer's recommendations for snow retention. Due to the relatively softer nature of aluminum roof panels compared to steel panels, it could be advisable to install extra rows of clamp-on snow rails to make up for the difference in panel strength.

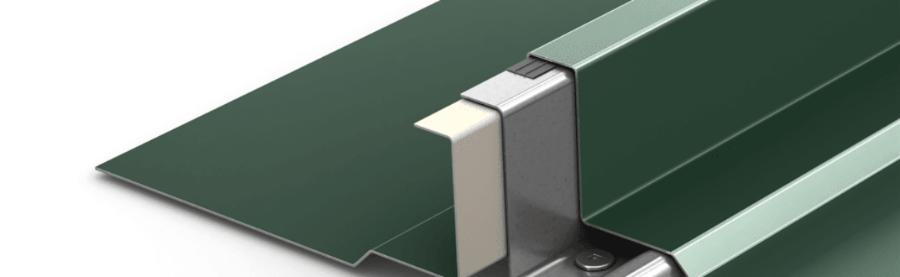

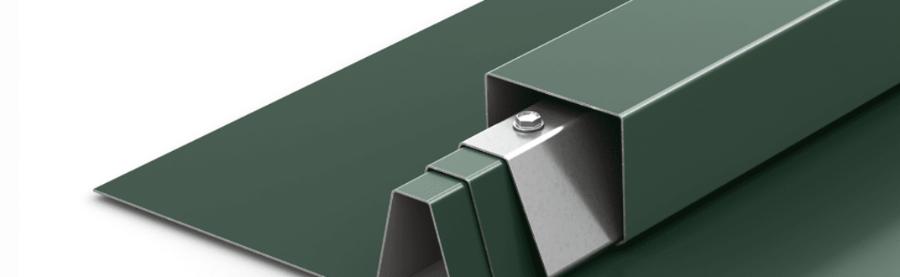

Tee-Lock Panel

The Tee-Lock panel is a versatile standing seam metal roofing and fascia system that combines aesthetic appeal with robust performance. Featuring a symmetrical 2-3/8 inch high T-shaped profile and an 18-inch coverage width, this panel offers a sleek and modern look. The Tee-Lock panel caters to diverse architectural preferences. It is available in various materials, including 24 and 22-gauge steel and 0.032 and 0.040 aluminum. Its surface finish options, including striated or smooth textures, enhance its visual appeal. The concealed fastener system contributes to a clean and seamless appearance, while the 2-3/8 inch standing mechanically seamed sidelap ensures exceptional weathertightness. One of the standout features of the Tee-Lock panel is its on-site roll-forming capability. Utilizing Berridge's TP-24 Roll Former, the panels can be formed in continuous lengths up to 40 feet, facilitating seamless installation and minimizing waste. This system is suitable for roofing and fascia applications, whether on open framing or solid sheathing. Backed by rigorous testing and certifications, the Tee-Lock panel offers superior performance in terms of wind resistance, fire resistance, and impact resistance. It has been evaluated and approved by Underwriters Laboratories (UL) and FM Approvals, ensuring compliance with industry standards for safety and durability. Additionally, the panel has undergone testing for wind and water resistance by ASTM standards, further validating its resilience against harsh environmental conditions. With its aesthetic appeal, material versatility, on-site roll forming capabilities, and proven performance, the Tee-Lock panel by Berridge is a compelling choice for architects, contractors, and building owners seeking a high-quality metal roofing and fascia solution. See the Snow Guards Compatibility Chart for Berridge Manufacturing Tee-Lock Panel Standing Seam Metal Roofing.

These roofing panels are suitable for various snow guard systems. To ensure the effective sealing of glue-down polycarbonate snow guards and prevent moisture infiltration, apply a more generous amount of adhesive to accommodate different panel ribs or striations. Inadequate sealing could lead to trapped snowmelt beneath the guards, resulting in refreezing and potential detachment, ultimately causing system failure. Customers seeking larger snow guard options compatible with this panel can choose from the IceJax II, Snojax II, or SnoBlox Ace systems. Conversely, those preferring a smaller footprint may opt for the Deuce or IceJax I models. The SnowBreaker and SnowBreaker 3M systems promote safer snow and ice shedding. This panel's T-shaped rib design allows for compatibility with the clamp-on SnoCleat RCT, SnoBar, and ColorBar systems when paired with the RCB-3 bracket and aluminum RoofClamp RCT attachments. While the panel features a mechanically fastened batten cap, it only covers the seam's top. It does not affect the clamp-on snow retention attachment. When working with aluminum roof panels, which are generally less sturdy than steel panels, the installation of clamp-on snow rails might call for the inclusion of supplementary rows to account for the variation in panel toughness.

Cee-Lock Panel

The Cee-Lock Panel is an innovative architectural metal panel system that seamlessly blends visual appeal with robust functionality. This standing seam panel is perfect for residential and commercial construction projects. It offers a distinctive aesthetic while ensuring superior weather resistance and longevity. At its core, the Cee-Lock Panel features an integral snap-lock seam that securely interlocks the panels, creating a weather-tight seal. This design can be further enhanced with an optional patented extruded vinyl weather seal, providing additional protection against the elements. Versatility is a hallmark of the Cee-Lock Panel, with standard 16-1/2" coverage or an optional 11-1/2" coverage to accommodate diverse project requirements. Available in durable 24 and 22-gauge steel or 0.032 aluminum, the panels offer a choice of smooth or rigid profile striations, the latter virtually eliminating waviness or oil-canning for a flawless appearance. Concealed fasteners contribute to a clean, seamless look, while the 1 1/2" high profile lends a distinctive architectural flair. Rigorously tested and certified, the Cee-Lock Panel meets various building code requirements and industry standards, including UL listings, ASTM tests, Florida Product Approvals, and Texas Department of Insurance listings for wind and fire resistance. This comprehensive compliance ensures peace of mind and adherence to stringent safety and performance criteria. Whether adorning roofs, fascias, or other architectural elements, the Berridge Cee-Lock Panel offers a harmonious blend of aesthetic sophistication and functional excellence, making it an ideal choice for discerning architects, builders, and homeowners alike. See the Snow Guards Compatibility Chart for Berridge Manufacturing Cee-Lock Panel Standing Seam Metal Roofing.

These metal roofing panels work with various snow retention systems, providing an excellent surface for adhering polycarbonate snow guards. Proper adhesive application is crucial to prevent moisture intrusion and potential issues like refreezing, which often ends with detachment. Customers can choose from larger solutions like the IceJax II, Snojax II, and SnoBlox Ace or smaller alternatives such as the SnoBlox Deuce and IceJax I, effectively retaining snow and ice on their roofs. The SnowBreaker and SnowBreaker 3M facilitate safer snow and ice shedding by breaking the snowpack into smaller chunks. When using glue-down polycarbonate snow guards with this panel, a thicker application of Surebond SB-190 adhesive may be necessary to compensate for the panel's striations, ensuring a secure and reliable installation. The rib design of these panels guarantees compatibility with various clamp-on snow guards, such as SnoCleat RCT and the SnoBar and ColorBar systems when using the RoofClamp RCT attachments, featuring aluminum construction with stainless steel cupped tip set screws. The optional vinyl Weatherseal featured inside the seams of this panel will prevent clamp-on snow guards and snow rail systems from achieving proper torque settings for secure attachment. Utilizing the optional Weatherseal will make these clamp-on snow retention options incompatible. Pad-style snow guards are generally unsuitable for curved roofs as they require a completely flat surface for proper installation, in which case snow rail systems are the appropriate solution. Suppose a clamp-on snow rail is incompatible with the curved panel's seams. In that case, it is advisable to consult the roofing manufacturer for their recommended snow retention methods.

Zee-Lock Panel

The Zee-Lock Panel caters to both residential and commercial projects. This panel features a 2-inch high mechanically seamed profile with a coverage width of 16 inches. Customers can choose from durable 24- or 22-gauge steel or 0.032 and 0.040 aluminum options, ensuring a robust and long-lasting solution. The Zee-Lock Panel presents a sleek and smooth finish and offers an optional striated surface for added visual interest. Its concealed fastener system contributes to a clean, contemporary aesthetic. These panels can be seamlessly formed on-site using Berridge's SP-21 Roll Former, and the mechanical seaming process is accomplished in a single pass using the Berridge Zee-Lock Seamer, ensuring a watertight seal. Among the key features of this panel are its continuous lengths up to 40 feet, suitability for straight or curved applications, and UL fire and impact resistance ratings. Additionally, the panel has undergone ASTM testing for wind and water resistance, ensuring its structural integrity and performance. The Zee-Lock Panel balances structural excellence and visual appeal, making it an ideal choice for projects where architectural excellence is a priority. See the Snow Guards Compatibility Chart for Berridge Manufacturing Zee-Lock Panel Standing Seam Metal Roofing.

These metal roofing panels offer a versatile range of glue-down pad-style snow retention solutions, from larger options like the IceJax II, Snojax II, and SnoBlox Ace to smaller alternatives such as the SnoBlox Deuce and IceJax I, effectively retaining snow and ice on roofs. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into more manageable, safer pieces. The panels' rib designs ensure compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems, offering flexibility in attachment options, with standard SnoBar Clamps made from stainless steel and RoofClamp attachments made of aluminum with cupped-tip stainless steel set screws. When using glue-down polycarbonate snow guards, these panels provide an excellent surface for adhering, but proper adhesive application with a thicker layer of Surebond SB-190 adhesive may be necessary to compensate for the panel's striations, ensuring a secure and reliable installation while preventing moisture intrusion and subsequent issues like refreezing or detachment. Pad-style snow guards typically aren't compatible with curved roofs since they need a completely flat surface for installation. In these cases, snow rail systems are the recommended choice. The installation of clamp-on snow rails on aluminum roof panels, which are typically softer than steel panels, may demand the addition of extra rows to offset the difference in panel strength.

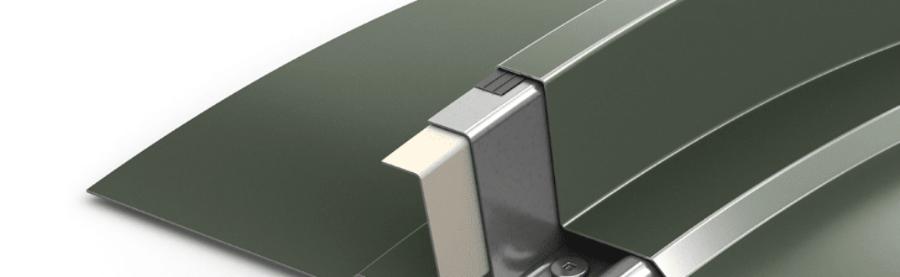

Curved or Tapered Zee-Lock Panel

The Curved or Tapered Zee-Lock Panel is another version of the Zee-Lock panel designed to incorporate visually striking curved or tapered rooflines into their designs. Constructed from high-quality 24 or 22-gauge steel, these panels feature a 2-inch standing mechanically seamed sidelap for a watertight seal. The standard 16-inch coverage width is available in smooth or striated finishes, offering design flexibility. A key advantage of this system is its ability to be curved or tapered on-site using specialized Berridge equipment. The ZC-21 Zee-Lock Curving Machine enables continuous curving of the panels to achieve a minimum radius of 20 feet for convex curves. At the same time, the TZ-21 Roll Former facilitates the creation of tapered panels. For curved applications, extruded vinyl Weatherseal ensures optimal watertightness. The Curved or Tapered Zee-Lock Panel system has undergone rigorous testing and certification processes. It is UL-rated for fire resistance and impact resistance. It has passed ASTM tests for wind and water resistance, ensuring durability and performance in various environmental conditions. This versatile system allows architects to blend form and function seamlessly, creating visually captivating and structurally sound curved or tapered rooflines. See the Snow Guards Compatibility Chart for Berridge Manufacturing Curved or Tapered Zee-Lock Panel Standing Seam Metal Roofing.

Pad-style snow guards do not work well on curved, radiused roofs because they require a perfectly flat surface for correct installation. We do not recommend installing pad-style snow guards on these panels when they are radiused. In these cases, snow rail systems are typically the appropriate choice. The panels' rib designs ensure compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems, offering flexibility in attachment options, with standard SnoBar Clamps made from stainless steel and RoofClamp attachments made of aluminum with cupped-tip stainless steel set screws. The optional Weatherseal in this particular panel design do not impact the attachment of clamp-on snow retention options.

Double-Lock Zee-Lock Panel

The Double-Lock Zee-Lock Panel is a high-performance structural standing seam metal roofing system designed for roofing and fascia applications. This panel boasts a distinctive 2-inch tall, 180-degree mechanically seamed sidelap, ensuring a secure and watertight connection between panels. With a coverage width of 16 inches, the panel is available in 24-gauge steel or 0.032 and 0.040 aluminum options. One of the key advantages of this panel is its versatility in installation methods. It can be installed over open framing or solid sheathing, providing flexibility to accommodate various project requirements. The panel's surface finish options include a smooth or striated texture, catering to different aesthetic preferences. See the Snow Guards Compatibility Chart for Berridge Manufacturing Double-Lock Zee-Lock Panel Standing Seam Metal Roofing.

The concealed fastener system also contributes to a clean and visually appealing appearance. The Double-Lock Zee-Lock Panel offers convenience in panel length and on-site fabrication. Continuous lengths up to 40 feet can be obtained directly from the factory, reducing the need for excessive seaming on the job site. Furthermore, the panel can be site-formed using Berridge's SP-21 Roll Former, allowing for customization and efficient installation. The Double-Lock Zee-Lock Seamer streamlines the field seaming process by completing the seaming in a single pass. To ensure quality and performance, the Double-Lock Zee-Lock Panel has undergone rigorous testing and has obtained various certifications. It is UL-classified for wind resistance, fire resistance, and impact resistance. Berridge tested this panel according to ASplagia standards for wind and water resistance. The panel is also Florida Product Approved, listed by the Texas Department of Insurance, and has an ICC-ES Report for capacity. Additionally, it is approved for military construction projects, further attesting to its durability and reliability. With its structural integrity, performance, and design flexibility, the Berridge Double-Lock Zee-Lock Panel presents a compelling choice for architects and contractors seeking a high-quality metal roofing solution for their projects.

These metal roofing panels offer a versatile range of snow retention solutions, from larger options like the IceJax II, Snojax II, and SnoBlox Ace to smaller alternatives such as the SnoBlox Deuce and IceJax I, effectively retaining snow and ice on roofs. The SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable chunks. The panels' rib designs ensure compatibility with clamp-on snow guards, including SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar systems, offering flexibility in attachment options, with standard SnoBar Clamps made from stainless steel and RoofClamp attachments made of aluminum with cupped-tip stainless steel set screws. When using glue-down polycarbonate snow guards, these panels provide an excellent surface for adhering, but proper adhesive application with a thicker layer of Surebond SB-190 adhesive may be necessary to compensate for the panel's striations, ensuring a secure and reliable installation while preventing moisture intrusion and subsequent issues like refreezing or detachment. Given the relatively lower strength of aluminum roof panels compared to steel panels, the installation of clamp-on snow rails might necessitate the incorporation of additional rows to address the disparity in panel robustness.

Batten Seam Panel

The Batten Seam Panel is a two-component metal roofing and fascia system that combines functionality with a contemporary, visually striking design. This innovative system comprises the Deep-Vee panel and square snap-on battens, creating a seamless, wide-seam aesthetic with concealed fasteners and a clean and polished appearance. Crafted from robust 24-gauge steel, the Batten Seam Panel offers exceptional durability and longevity. With a 16-inch panel coverage and 2-inch wide, 1-3/4-inch high snap-on batten caps, the system adds a bold and distinctive character to any structure. The panels can be installed over open framing or solid sheathing, providing versatility in application. One of the standout features of this system is the availability of continuous panel lengths up to 40 feet, obtainable directly from the factory or formed on-site using the Berridge BP-21 Roll Former. This flexibility ensures a seamless and cohesive look, minimizing visible joints and enhancing aesthetic appeal. The Berridge Batten Seam Panel incorporates batten clips spaced at 20-inch intervals along each panel rib to ensure secure attachment. Additionally, batten end caps provide a watertight mechanical closure at the panel bottom, ensuring optimal protection against the elements. When installed with specific assemblies, the Berridge Batten Seam Panel system has achieved a UL 90 wind uplift rating and various UL fire resistance ratings. This certification underscores the system's ability to withstand harsh environmental conditions while maintaining its structural integrity. Suitable for roofing and fascia applications, the Batten Seam Panel is an excellent choice for residential, commercial, and institutional buildings with a desired modern panel line look. Its durability, design flexibility, and visual appeal make it popular among architects, contractors, and homeowners seeking a distinctive, polished roofing solution. See the Snow Guards Compatibility Chart for Berridge Manufacturing Batten Seam Panel Standing Seam Metal Roofing.

The roofing panel features a wide batten cap for the seam, making specific snow retention methods incompatible. Specifically, we do not recommend using clamp-on individual snow guards like the SnoCleat RC and SnoCleat RCT or clamp-on snow rail systems like the SnoBar and ColorBar for this panel. The clamps would only attach to the strip, failing to provide the proper torque on the main panels. None of our clamps have adequate interior dimensions to straddle this seam. Still, if they could, they would crush it, which could lead to the strips disengaging from the roof, resulting in significant and costly repairs. On the other hand, this panel is compatible with various glue-down polycarbonate snow guards, such as the SnoBlox Deuce, SnoBlox Ace, IceJax II, and Snojax II. These solutions offer a safer and more controlled snow and ice retention method. In addition, the SnowBreaker and SnowBreaker 3M products are recommended for those seeking to break the ice and snow into smaller and safer pieces, slowing its release from the roof. The recommended adhesive for polycarbonate snow guards is Surebond SB-190, the industry standard for these systems.

Snow Guards Compatibility Chart For Berridge Manufacturing

| Tee-Panel Profile | Curved or Tapered Tee-Panel Profile | High Seam Tee-Panel Profile | Curved or Tapered High Seam Tee-Panel Profile | Tee-Lock Panel Profile | Cee-Lock Panel Profile | Zee-Lock Panel Profile | Curved or Tapered Zee-Lock Panel Profile | Double-Lock Zee-Lock Panel Profile | Batten Seam Panel Profile | |

|---|---|---|---|---|---|---|---|---|---|---|

| IceJax I Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| IceJax II Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| SnoBlox Deuce Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| SnoBlox Ace Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| Snojax II Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| SnowBreaker Glue Down | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| SnowBreaker 3M | YES | NO | YES | NO | YES | YES | YES | NO | YES | YES |

| SnoBar Standing Seam | NO | NO | NO | NO | NO | NO | YES | YES | YES | NO |

| ColorBar Standing Seam | NO | NO | NO | NO | NO | NO | YES | YES | YES | NO |

| SnoBar RCB-3 | NO | NO | NO | NO | YES | YES | YES | YES | YES | NO |

| ColorBar RCB-3 | NO | NO | NO | NO | YES | YES | YES | YES | YES | NO |

| SnoBar 2-Bar | NO | NO | NO | NO | YES | YES | YES | YES | YES | NO |

| ColorBar 2-Bar | NO | NO | NO | NO | YES | YES | YES | YES | YES | NO |

| SnoCleat RC | NO | NO | NO | NO | NO | NO | YES | YES | YES | NO |

| SnoCleat RCT | NO | NO | NO | NO | YES | YES | YES | YES | YES | NO |

Snow Guard Considerations for Berridge Standing Seam Roofing

Test fit your snow retention components.

Before going all-in, it's an excellent idea to test-fit any snow guards, clamps, brackets, or IceStoppers to make sure they'll work with your project. You can order samples from our website without any minimum orders, and we've got 27" and 20" bar sample kits, too. Testing compatibility upfront can save you from costly mistakes down the line, so it's a smart move.

Color-Matching for a Seamless Look

Our metal snow retention products can match your roof's color for a clean, integrated look. SnoCleat RC, SnoCleat RCT, and ColorBar Snow Rail Systems use slide-in metal strips that blend the system's face with your roof color. You can buy these strips with the system or make them from leftover roofing materials on-site. We also offer custom powder coating for our systems, which may add extra lead time and cost.

Layout is Paramount

Getting the layout right is crucial for peak performance, regardless of your system. We provide free advice, resources, spacing charts, and custom quote request forms to help. Ideally, your system should span the entire roof length with multiple ascending rows to distribute weight evenly. Install individual guards in a staggered pattern and mount rails in straight lines. Avoid installing guards over isolated areas, which can overload the system and lead to failure. If using SnowBreaker, the isolated placement rules are different; we've got guidelines for that.

Bring on the IceStoppers

For SnoBar or ColorBar rail systems on standing seam roofs, we highly recommend adding IceStopper attachments—especially over walkways, entrances, and parking areas. IceStoppers can be installed during the initial setup or retrofitted later. Proper spacing is critical for effectively managing snow and ice buildup. They become even more important for seams over 1" tall since ice can slide under the bar on taller seams without IceStopper protection.

Time it Right for Glue-Down Snow Guards

While clamps and rails can go on year-round, timing matters for glue-down polycarbonate snow guards. The standard Surebond SB-190 adhesive needs about 28 days at 50°F to cure fully. For best results in the US and Canada, plan glue-down installs for late spring or early summer. Rain shouldn't be an issue after 24 hours. However, we don't recommend using SB-190 on copper roofs, as chemical reactions could accelerate corrosion.

Know Your Ground Snow Load

Knowing your ground snow load is critical when choosing snow retention for metal roofs. Most individual guards and rails can handle up to 45 psf (pounds per square foot) with no problem. But if you're in an area with heavier snow loads, you'll need beefier snow rails. Individual pad-style guards won't cut it. If your roof panels can't use rails and your load exceeds 45 psf, check with the panel manufacturer for their recommended solution. To find your local ground snow load, ask your building inspector or search online for "[your town] ground snow load."

Avoid Screwing Into Standing Seam Metal Roofing

Installing screw-down snow guards or rails on standing seam metal roofs is a recipe for disaster. That approach risks your panels due to how the roof expands and contracts. You could end up with leaks, costly repairs, and voided warranties. Use clamp-on or adhesive-mounted systems for standing seams to ensure a secure, compatible installation.

In Conclusion

Look out for more brand-specific content coming soon! Working with a company that quickly answers your questions and guides you is critical. At SnoBlox-Snojax, we pride ourselves on our full support every step of the way. Reach out anytime at support@snojax.com or 1-800-766-5291. Our Snow Guard Buyer's Guide and "What Works and Doesn't" page also contain helpful information. We're here to ensure you get the perfect snow guards and make the process smooth.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.