Snow Guards For Exposed Fastener Metal Roof Panels by Chief Buildings

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 19th 2024

See the Snow Guards Compatibility Chart for Chief Buildings Exposed Fastener Metal Roofing Panels.

"What Are the Best Snow Guards for Metal Roofs?"

Safeguarding residential, commercial, and industrial buildings with exposed fastener metal roofs against the potential hazards of sliding snow and ice accumulations is crucial. These roofing systems often require comprehensive snow retention solutions tailored to withstand harsh winter conditions. This guide explores various snow guard options compatible with Chief Buildings' exposed fastener metal roof panel, enabling the selection of the most suitable solution for each roof system's unique requirements. As part of an ongoing informative blog series highlighting prominent metal panel manufacturers and recommending compatible snow retention solutions, the aim is to empower readers with the knowledge necessary to make well-informed decisions that safeguard investments while ensuring safety during unforgiving winter months. Implementing appropriate measures mitigates risks associated with sliding snow and ice, protecting property, occupants, and pedestrians from potential harm by considering factors such as roof pitch, snow load, and environmental conditions.

Exposed Fastener Metal Roof Panels by Chief Buildings

Chief Buildings, a family-owned and operated enterprise rooted in Grand Island, Nebraska, has carved a remarkable path in the metal building industry, offering a comprehensive array of construction solutions tailored to manufacturing, commercial, community, and agricultural sectors. Chief Industries has a rich history that spans over six decades, with its roots tracing back to 1954 when Eihusen Construction Company embarked on remodeling single-family homes. This division continues to thrive today as Chief Construction. In 1959, the company ventured into manufacturing grain bins at its Grand Island facility, named Big Chief of Nebraska. This business unit has since evolved into Chief Agri in Kearney, Nebraska. The year 1966 marked a significant milestone as the company began manufacturing metal buildings. This division has endured and flourished as Chief Buildings, operating from its expanded Grand Island offices and manufacturing plant. Two years later, Big Chief of Nebraska underwent a name change, becoming Chief Industries, and opened a grain bin manufacturing facility in Rensselaer, Indiana, which is currently run by the Buildings division, producing metal buildings. In 1970, Chief Industries diversified its offerings by adding the production and distribution of manufactured homes in Aurora, Nebraska. This division continues to operate today under the name of BonnaVilla. Six years later, the company formed Chief International, Inc. and acquired Caldwell Manufacturing Company, expanding its product line to include grain storage and aeration equipment, which now fall under the Chief Agri banner. The year 1984 witnessed the split of the OEM fabrication services from Chief Buildings as a separate business unit, which now exists as Chief Fabrication, located in Grand Island, Nebraska. In 1987 and 1997, Chief Buildings expanded its manufacturing capabilities by establishing additional plants in Rensselaer, Indiana. Chief Industries continued to grow and evolve, with the establishment of its Powder Coating department in 1998, which currently operates under the Chief Fabrication banner. In 2001, Arrowhead Steel Products began the fabrication of structural steel. This business unit now operates as Arrowhead Steel Fabricators under the Chief Buildings banner. The company's growth trajectory continued with the incorporation of Chief Construction Company in Grand Island, Nebraska, in 2005 and the opening of remote detailing/drafting locations for Chief Buildings in Lincoln, Nebraska, in 2007 and Fort Dodge, Iowa, in 2017. Celebrating significant milestones, Chief Industries marked its 65th anniversary in 2019, while Chief Buildings celebrated its 55th anniversary in 2021. Most recently, in 2022, Chief Buildings opened its third manufacturing plant in Lancaster, South Carolina, further expanding its footprint and capabilities.

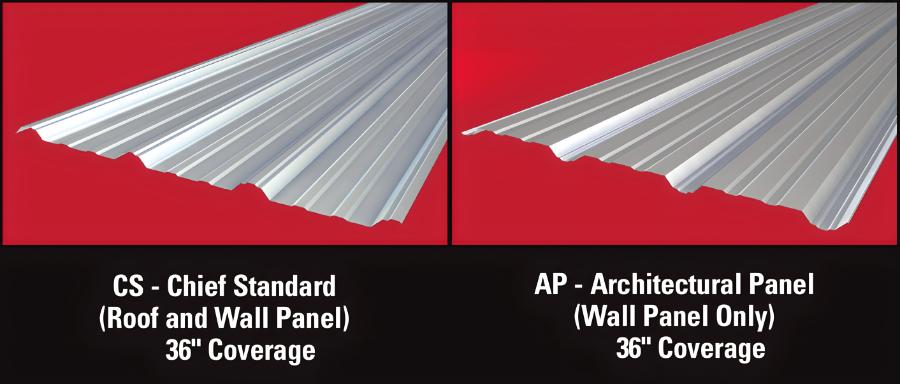

CS Panel

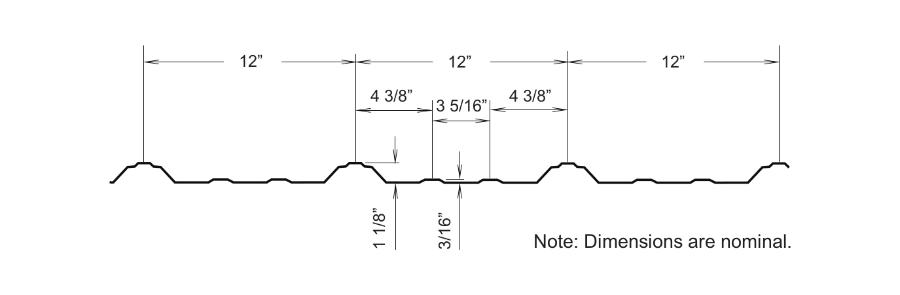

The CS Panel is a corrugated metal roofing solution offered by Chief Buildings for their pre-engineered steel building systems. This through-fastened panel design features major structural ribs spaced at 12-inch intervals. These panels are directly secured to the roof purlins using exposed fasteners. While the standard panel length is 30 feet, Chief Buildings can customize these panels up to 45 feet long to meet specific project requirements. Constructed from durable 26 or 24-gauge galvalume steel, the CS Panels are coated with a high-performance Kynar 500 or Hylar 5000 paint system, ensuring long-lasting color retention and resistance to harsh environmental conditions. The panels interlock together using a triple-lap design, creating a weathertight seal that protects the building's interior from the elements. To complement the CS Panel roofing system, Chief Buildings offers a range of accessories, including panel splices, ridge caps, gable trims, and closures. These components ensure a seamless and professional installation, enhancing the overall aesthetic appeal and functionality of the roofing system. With its economical pricing and versatile design, the CS Panel from Chief Buildings is a popular choice for industrial, commercial, and agricultural applications, providing a cost-effective and durable roofing solution for pre-engineered metal buildings. See the Snow Guards Compatibility Chart for Chief Buildings CS Panel Exposed Fastener Metal Roofing.

The CS panel system offers remarkable versatility when it comes to installing snow guards, catering to diverse preferences and project requirements. These panels integrate with a wide range of snow guard models, providing flexibility in design and functionality. Among the compatible options are the screw-down SnoBar and ColorBar snow rail systems, the SnoCleat PBR, and the stainless steel SnowCatchers, which include designs such as the Standard Rectangle, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak. Additionally, most polycarbonate snow guard models, except for the Snojax I, can be affixed to these panels using adhesive or mechanical fasteners. It is important to note that the Snojax I requires installation solely with mechanical fasteners. When working with polycarbonate models, you must use the Surebond SB-190 adhesive, as its formulation ensures compatibility with these materials; however, this adhesive is unsuitable for metal pad-style snow guards. You should mount smaller snow guards between the minor ribs centered on the panels for optimal installation. At the same time, specific models, such as the Snojax II and Icejax II, require off-center mounting, straddling either the left or right minor rib, and consistent placement over the same rib is crucial in these cases. It is essential to avoid securing individual snow guards or rail systems directly onto the high ribs of the panel. Instead, the recommended approach is to fasten them by screwing through the panel's low flats into a solid underlying structure, ensuring maximum installation strength and stability.

Chief Buildings Compatibility Chart for Snow Guards

| CS/AP Profile | |

|---|---|

| IceJax I Screw Down | YES |

| IceJax I Glue Down | YES |

| IceJax II Screw Down | YES |

| IceJax II Glue Down | YES |

| SnoBlox Deuce Screw Down | YES |

| SnoBlox Deuce Glue Down | YES |

| SnoBlox Ace Screw Down | YES |

| SnoBlox Ace Glue Down | YES |

| Snojax I Screw Down | YES |

| Snojax II Screw Down | YES |

| Snojax II Glue Down | YES |

| SnowBreaker 3M | YES |

| SnowBreaker Screw Down | YES |

| SnowBreaker Glue Down | YES |

| SnowCatcher | YES |

| Decorative SnowCatcher | YES |

| SnoCleat PBR | YES |

| SnoCleat 2.67 | NO |

| SnoBar PBR | YES |

| ColorBar PBR | YES |

| SnoBar 2.67 | NO |

| ColorBar 2.67 | NO |

Considerations for Purchasing and Installing Snow Guards for Chief Buildings Exposed Fastener Metal Roofing

When to Install Adhesive Snow Guards

While you can install screw-down snow guards and rail systems year-round (as long as the roof is clear of snow, ice, and debris), you'll need to plan carefully for adhesive-based snow guard installations. The standard adhesive used for polycarbonate snow guards, SureBond SB-190, needs around 28 days at 50°F to cure fully. The best time to install in the US and Canada is late spring or early summer. Colder temperatures won't damage the adhesive, but they'll pause the curing until it warms up again.

Matching Colors

We offer various solutions to ensure our snow retention systems blend in seamlessly with your roof color, creating an attractive installation. These options include interchangeable color strips that slide easily into the faces of our SnoCleat and ColorBar products, allowing you to match the snow guards' to your roof's shade. We also offer powder-coating services for all metal snow guards to ensure a complete coverage color match. Powder-coated products take longer (approximately 3-4 weeks) due to custom manufacturing. Still, you can also choose to have them powder-coated locally or painted on-site for faster turnaround and more color control.

Determining Snow Loads

To pick the right snow retention system, we consider historical weather data. Meteorologists use this information to calculate your ground snow load. For areas with loads up to 45 PSF, consider adhesive or mechanically fastened individual snow guards or screw-down rail systems. We recommend only using rail systems when loads exceed that threshold. You can find your local ground snow load information online, in your building plans, or by contacting your local officials.

Ensuring Solid Structural Support

When installing mechanically fastened snow guards, anchoring them into at least 1 inch of solid wood structure like plywood decking, purlins, or retrofitting blocking is crucial. For pre-engineered metal buildings, mount them directly into the metal purlins whenever possible. Don't rely on just the panel to support the snow guards or rails, as that increases failure risk. If the structure under the proposed mounting points is inadequate and your ground snow load is 45 psf or less, consider using an adhesive product if the installer can't easily add extra blocking.

Keeping Your Roof Watertight

Products like SnoCleat PBR, SnoCleat 2.67, SnowCatchers, and screw-down rail systems use butyl tape gaskets to create a secure seal against the elements, so you don't need liquid sealants. Combined with screws that have neoprene washers, you get a watertight installation. Some customers add an extra layer of protection by applying a neutral-curing, cold-weather liquid silicone like Novaflex MR150 around the snow guards' edges. For polycarbonate snow guards attached with screws, you must use this type of liquid silicone to seal the entire base effectively.

Planning a Comprehensive Layout

No matter what snow retention system you choose, get a design recommendation from the manufacturer. We provide free spacing charts and quote request forms to help customers who need custom layout guidance. Just keep in mind that installing snow retention in isolated areas is never recommended, as it consistently poses a high risk of failure and potential safety issues.

Conclusion

SnoBlox-Snojax prioritizes providing an outstanding experience as you install our snow guards. Our team of experts is readily available to address any inquiries or concerns. Feel free to contact us via email at support@snojax.com or our dedicated support hotline at 1-800-766-5291. We have curated a comprehensive collection of valuable resources to empower our customers. Our Snow Guard Buyer's Guide offers in-depth insights and guidance to assist you in making well-informed decisions throughout the selection process. Additionally, our "What Works and Doesn't" page provides practical perspectives on best practices and potential pitfalls, ensuring a smooth and successful installation journey. We encourage you to leverage these resources to gain confidence and make informed choices when selecting and installing our snow guard solutions. Our commitment is to provide you with the knowledge and support necessary for a seamless and satisfactory experience.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.