Snow Guards for MBCI Exposed Fastener Metal Roofing

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Mar 28th 2024

See the Snow Guards Compatibility Chart for MBCI Exposed Fastener Metal Roofing Panels.

Our new blog series aims to ease this process by exploring some leading metal panel brands and recommending suitable snow guard solutions tailored to the MBCI exposed fastener metal roof panels. In today's market, the array of metal roofing brands and panel options can make selecting the ideal snow guard for your project quite daunting. While the abundance of choices may initially appear like an excellent problem to have, it often presents a challenge when it comes to decision-making. Let's get into it!

MBCI Exposed Fastener Metal Roofing

Following our previous blog post highlighting MBCI's standing seam roofing panels, we will focus on their range of exposed fastener roof panels today. Since its founding in 1976, MBCI has continuously dedicated itself to providing high-quality metal building components known for their dependability. In the heart of Houston, Texas, MBCI operates manufacturing facilities and sales offices strategically positioned across the United States. Their extensive catalog boasts over 90 metal roof and wall panel profiles, complemented by various secondary structural components, trim, and associated accessories.

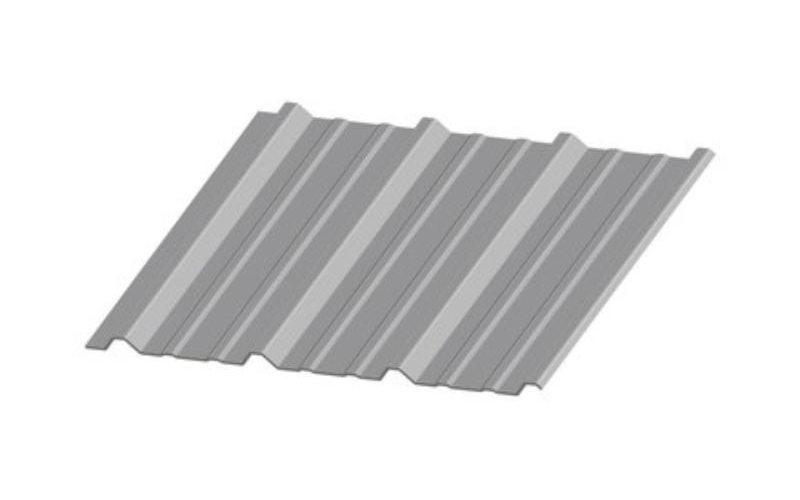

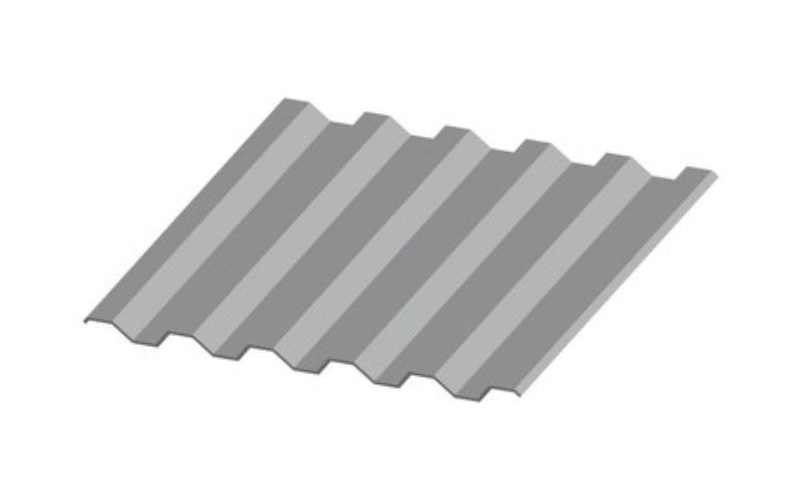

PBR Metal Roofing

Architects, farmers, commercial businesses, and industrial companies widely use MBCI's PBR metal panel (R panel) in their projects and facilities. These panels offer versatility and durability as a resilient alternative to traditional materials for siding and roofing purposes. You can tailor MBCI's R Panel profile to various specifications, including coatings, color choices, purlin-bearing legs, substrates, and more. These panels adapt seamlessly to your building's design requirements, whether installed vertically or horizontally. You can directly install these through-fastened panels over purlins or joists. This 36" wide panel features 1-1/4" tall high ribs on 12" center-to-center spacing with two minor ribs spaced evenly between them. The PBR panel has a minimum pitch requirement of ½:12 and is available in 22, 24, and 26 gauge thickness options. See the Snow Guards Compatibility Chart for MBCI PBR Exposed Fastener Metal Roofing Panels.

PBR panels are exceptionally versatile exposed fastener panels for snow guard installations, offering many choices. These panels work well with our screw-down SnoBar and ColorBar snow rail systems, the SnoCleat PBR, all stainless steel SnowCatcher Models (including Standard, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak), and every polycarbonate snow guard in our catalog. All polycarbonate models, except for the Snojax I, can be installed using adhesive or screws. The industry standard adhesive for applying polycarbonate snow guards is Surebond SB-190. Avoid using this adhesive for metal pad-style snow guards. It's important to note that while most options require mounting the snow guard in the center flat of the panels, some guards may need to be mounted off-center to straddle either the left or right minor rib. Maintaining consistent mounting over the same rib is crucial in such cases.

It's crucial to always secure them by screwing down through the low flats of the panel into a sturdy structure for optimal installation strength.

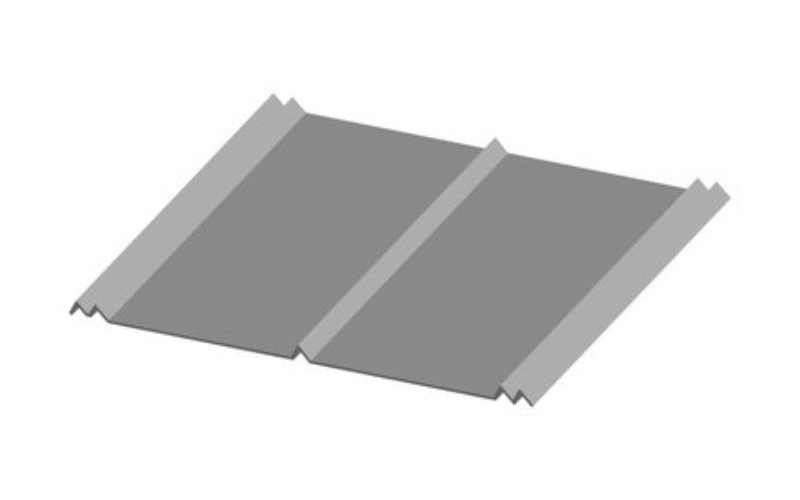

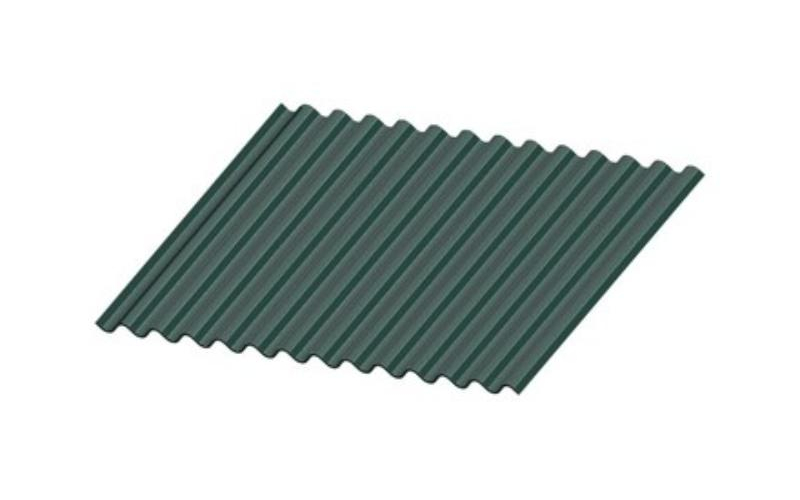

5V CRIMP Metal Roofing

The 5V Crimp roof panel embodies a classic, nostalgic aesthetic perfect for residential applications while lending itself well to light commercial projects. Installation requirements include a strong roof deck with a waterproof membrane and a minimum slope of 3:12. Featuring alternating single and double ribs spaced roughly every 12 inches, these 24-inch panels are available in 26 and 29-gauge thicknesses.

The 5V Crimp roof panel offers compatibility with various snow retention options. You can install metal screw-down individual pad-style snow guards on this panel, such as our stainless steel SnowCatchers in Standard, Sun Burst, Maple Leaf, Fleur-de-lis, Kodiak, and Mustang shapes. This panel is also compatible with all of our polycarbonate pad-style snow guards as well. Install all of our polycarbonate models, such as the SnoBlox Deuce, Icejax II, and SnoBlox Ace, on this panel with screws or glue if you aim to secure snow and ice on the roof, except for the Snojax I, which requires screws for installation. Customers wanting to allow the snow and ice to shed from their roofs while slowing it down and breaking it into smaller, safer pieces may opt for the SnowBreaker product. Customers looking for a sleek, modern snow retention system and those living in high snow load areas should pivot to our SnoBar and ColorBar snow rail systems. Contractors install these heavy-duty snow fences using mechanically fastened ColorBrackets that feature butyl tape gaskets. See the Snow Guards Compatibility Chart for MBCI 5V Crimp Exposed Fastener Metal Roofing Panels.

7.2 PANEL Metal Roofing

When seeking an exposed fastener panel for your commercial or industrial project, consider the 7.2 Ribbed Panel. With its 7.2 rib design, this durable metal panel presents versatility and practicality for roofing and wall applications. Its symmetrical rib structure provides exceptional spanning and cantilever capabilities, making it suitable for carports and walkway canopies. The straightforward installation process also ensures swift project completion, allowing for a rapid turnaround. This panel has a minimum slope requirement of 1/2:12 and is available in 22, 24, and 26 gauge thickness options. See the Snow Guards Compatibility Chart for MBCI 7.2 Exposed Fastener Metal Roofing Panels.

The 7.2 Panel's low panel flats are only 1 1/2" wide, limiting your installation options. The polycarbonate SnoBlox Deuce allows customers to hold snow and ice on their roofs with a pad-style guard. You can install this snow guard with either screws or adhesive. The SnowBreaker product can break up the snow and ice into smaller, safer pieces as it sheds from the roof. This panel will also work well with our galvanized SnoBar and Aluminum ColorBar snow rails. Both options use the aluminum Tall ColorBracket for attachment, which is 1.5" wide.

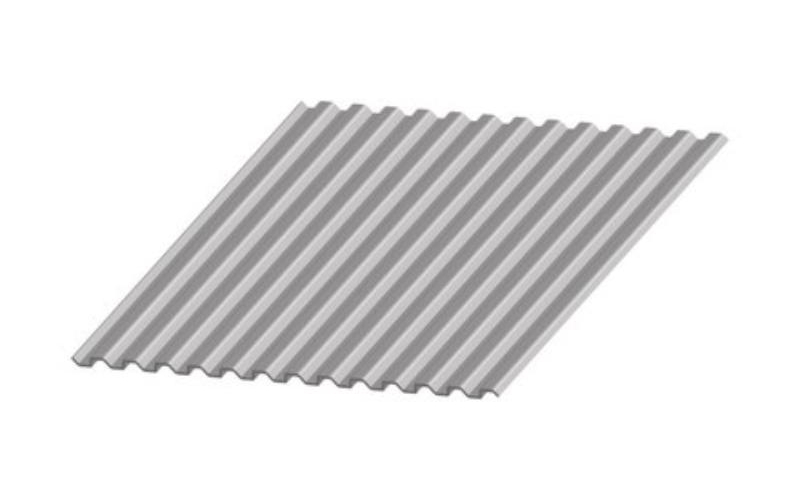

PBC Metal Roofing

The PBC panels are suitable for both roof and wall installations. PBC 2.67 wavy corrugated panels are fastened to a building structure using visible fasteners. PBC wavy corrugated metal roofing and wall panels are also commonly utilized in horizontal applications on walls. The 32" wide panels with 7/8" rib height have a minimum pitch requirement of 3:12 and are available in 22, 24, and 26 gauge thickness options. See the Snow Guards Compatibility Chart for MBCI PBC Exposed Fastener Metal Roofing Panels.

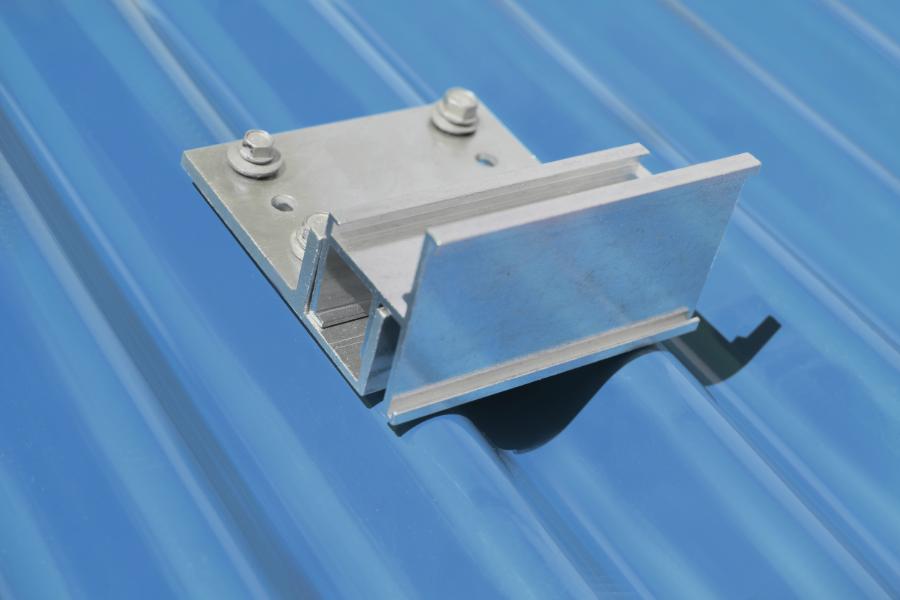

This particular panel does not include panel flats, making it unsuitable for most traditional pad-style snow retention methods that require flats for installation. Customers who choose this panel and seek an individually mounted solution can opt for our SnoCleat 2.67 snow guards. This recently released product can straddle two high ribs on the panel for proper attachment. It utilizes 3" long screws for secure attachment. Unlike standard exposed fastener roofing styles, the unique shape and design of wavy corrugated panels make them an exception to the rule regarding mounting on high ribs. Customers interested in a snow rail or snow fence system for their projects can equip their roof with our SnoBar or ColorBar snow retention systems with the same bracket used for the SnoCleat 2.67, enabling continuous runs of railing on the roof. Each 2.67 ColorBracket comes with six attachment holes. While four screws are sufficient for each bracket, the additional two holes can be utilized to enhance mounting strength, particularly in more extreme conditions.

PBD Metal Roofing

The PBD panel represents an exposed fastening system suitable for roofing and wall installations. Characterized by symmetrical ribs extending from top to bottom, the PBD panel is an excellent choice for roof lining. These panels, measuring 32 inches in width with a rib height of 5/8 inches, call for a minimum pitch of 3:12 on the roof and are offered in thickness options of 22, 24, and 26 gauge. See the Snow Guards Compatibility Chart for MBCI PBD Exposed Fastener Metal Roofing Panels.

Although the ribs on this panel are trapezoidal rather than round and wavy like the PBC, the flats are too narrow for snow guards that require flat mounting areas for installation. Because the PBC shares the 2.67" spacing dimensions, you can utilize the SnoCleat 2.67, SnoBar, or ColorBar systems with the same 2.67 brackets for all three products. This panel has the same installation guidelines as a traditional wavy corrugated panel.

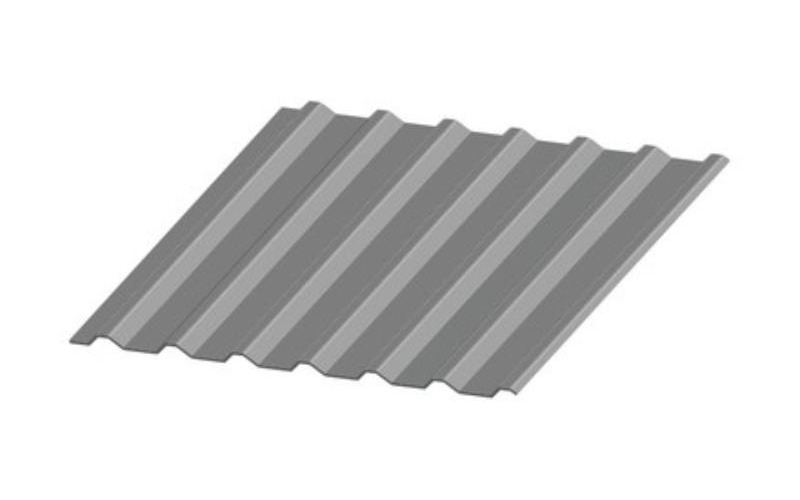

PBU Metal Roofing

The PBU panel presents an exposed fastener system suitable for roofing and wall purposes. MBCI's PBU metal panels, or U panels, are one of the industry's most versatile and cost-effective options. MBCI's U Panel roofing and siding provides extensive design flexibility, accommodating vertical or horizontal installation. This metal panel, featuring an exposed fastener system, ensures durability and high-quality performance over time. Distinguished by a lower profile and a softer aesthetic compared to R panels or Multi-Rib options, the U-Panel is frequently employed as a liner panel or partition wall, lending a contemporary look to various building projects. You can conveniently install these through-fastened panels directly over purlins or joists. This panel features an overall width of 36" with 3/4" tall ribs on 6" center-to-center spacing, a minimum slope requirement of 1:12, and available thickness options of 22, 24, and 26 gauge. See the Snow Guards Compatibility Chart for MBCI PBU Exposed Fastener Metal Roofing Panels.

The PBU panel features low panel flats approximately 3 1/2" wide. The width of the flat areas limits the options for this panel, but there are still plenty of choices available. Customers wanting to hold the snow and ice on their roofs should look at the Ace, Deuce, or Icejax I for individual pad-style polycarbonate snow guards. If the goal is to allow the snow and ice to shed in small, safer pieces in a slower, controlled manner, then the SnowBreaker or SnowBreaker 3M are the snow guards for you. You can install all of these models with screws or Surebond SB-190 adhesive. Tall ColorBrackets allow mechanically fastened SnoBar and ColorBar to be attached to this panel.

PERMA-CLAD® Metal Roofing

The Perma-Clad® panel system offers versatile applications for both roofing and wall installations. Suitable for residential, light commercial, agricultural, and storage structures, as well as canopies, Perma-Clad® excels in various settings. Installation of the Perma-Clad® panel on a sturdy, waterproof deck when utilizing it as a roofing panel is imperative for its success. Perma-Clad® features a 36" wide standard R-Panel design with 5/8" tall ribs on 9" spacing with two minor ribs spaced evenly between them. This panel is available in 26 and 29-gauge thickness options and has a minimum slope requirement of a 3:12 pitch. See the Snow Guards Compatibility Chart for MBCI PERMA-CLAD Exposed Fastener Metal Roofing Panels.

This panel accommodates both glue-down and screw-down options for a variety of guards. The SnoBlox Deuce and SnowBreaker are great for use with either attachment method centered between the minor ribs. SnoCleat PBR and all 6 SnowCatcher shapes are excellent for use with this panel if you are looking to mount a metal snow guard in the center flat of the panel with screws. Snojax I and Icejax I can also be utilized with this panel when straddling one of the minor ribs between each 9" rib. While you can install the Icejax I with glue or screws, the Snojax I only allows for mechanical fastening. ColorBar and SnoBar are again compatible with this panel when using the Tall ColorBackets and mechanical fasteners.

RAIN GUARD® Metal Roofing

Rain Guard® proves to be a highly effective panel for repelling water. Rain Guard® is an optimal roofing and siding panel suitable for various applications, including residential, light commercial, agricultural, canopies, and storage buildings. Installing the Rain Guard® panel atop a sturdy, waterproof deck as a roofing panel is imperative. This 36" wide panel features a design similar to Perma-Clad®. Instead of having its major ribs on 9" spacing, this panel features its ribs on 6" spacing with a height of 15/32". This panel has a minimum slope requirement of 3:12 with available gauge thickness options of 26ga. and 29ga. See the Snow Guards Compatibility Chart for MBCI RAIN GUARD Exposed Fastener Metal Roofing Panels.

Unfortunately, there was inadequate information about this panel's profile to recommend a snow guard. Based on our research, this panel's primary rib and minor rib spacing are too narrow to accommodate our snow guards. Still, we recommend reaching out to MBCI for more information. We also recommend purchasing a sample for a test fit before placing an order for your entire project.

STORMPROOF® Metal Roofing

The Stormproof® panel system presents an exposed, fastened solution suitable for roofing and wall applications, catering to various needs, including agricultural, light commercial, residential, and storage buildings. For roof applications, the Stormproof® panel necessitates installation over a sturdy, waterproof deck, boasting a coverage width of 36 inches. Additionally, MBCI introduces Drip Stop, an innovative product integrated into the Stormproof® panel during manufacturing. Drip Stop creates pockets within the felt's membrane to trap moisture effectively. This cost-effective alternative can save up to 25% on labor costs. Drip Stop upholds rigorous standards of durability and efficiency, ensuring it remains resilient against ripping, tearing, or deterioration commonly associated with standard insulation and vapor barriers. Moreover, it carries UL 723-Approval for flame spread and smoke generation, accompanied by a 20-year adhesion warranty, further underscoring its reliability. See the Snow Guards Compatibility Chart for MBCI STORMPROOF Exposed Fastener Metal Roofing Panels.

The Stormproof® panel system, much like PERMA-CLAD®, is a 9" R-Panel with 3/4" tall ribs. This panel is more suited for glue-down pad-style guards, as it is intended primarily for roofs without decking underneath for the membrane to work effectively. The SnowBreaker and Deuce will fit perfectly in the center flats of the panel, making them excellent choices for this roof. You can easily install them with adhesive. Icejax I is compatible with this panel but requires straddling one of the minor ribs. While this panel's shape will fit a variety of our screw-down snow guard and snow rail systems, we recommend contacting MBCI before placing your order for a mechanically fastened snow retention system for this panel. It is always better to be safe than sorry.

WEATHERSAFE® Metal Roofing

MBCI's WeatherSafe® panels offer versatile applications for roofing and wall installations, catering to various structures, including residential, light commercial, agricultural, and storage buildings. Moreover, WeatherSafe® finds utility in canopy structures and employs an exposed fastened system. For roofing purposes, it necessitates installation over a secure, waterproof deck. This 36" wide panel features 7/8" tall high ribs on 12" center-to-center spacing with two minor ribs spaced evenly between them. The WeatherSafe® panel has a minimum pitch requirement of 3:12 and is available in 26 and 29-gauge thickness options. See the Snow Guards Compatibility Chart for MBCI WEATHERSAFE Exposed Fastener Metal Roofing Panels.

WeatherSafe® is compatible with various snow retention methods, including our screw-down SnoBar and ColorBar Rail Systems with Tall ColorBrackets, the SnoCleat PBR, and all of the stainless steel SnowCatcher Models, including the Standard, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak shapes. Additionally, every polycarbonate snow guard in our catalog is compatible with WeatherSafe®. Unlike all other polycarbonate guards in our lineup, the Snojax I requires a screw-down installation ONLY as it is incompatible with Surebond SB-190 adhesive. You can install all our other polycarbonate models with either glue or screws. Never install metal pad-style snow guards with adhesive.

When installing snow guards, place some of our models in the center flat of the panels. Specific guards, like the Snojax II and Icejax II, may need to be mounted off-center to straddle either the left or right minor rib. Consistently maintaining mounting over the same rib is essential in such instances.

MBCI Snow Guards Compatibility Chart

| PBR Profile | 5V Crimp Profile | 7.2 Panel Profile | PBC Profile | PBD Profile | PBU Profile | Perma-Clad Profile | Rain Guard Profile | WeatherSafe Profile | ||

|---|---|---|---|---|---|---|---|---|---|---|

| IceJax I Screw Down | YES | YES | NO | NO | NO | YES | YES | YES | YES | YES |

| IceJax I Glue Down | YES | YES | NO | NO | NO | YES | YES | YES | YES | YES |

| IceJax II Screw Down | YES | YES | NO | NO | NO | NO | NO | NO | NO | YES |

| IceJax II Glue Down | YES | YES | NO | NO | NO | NO | NO | NO | NO | YES |

| SnoBlox Deuce Screw Down | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnoBlox Ace Screw Down | YES | YES | NO | NO | NO | YES | NO | NO | NO | YES |

| SnoBlox Ace Glue Down | YES | YES | NO | NO | NO | YES | NO | NO | NO | YES |

| Snojax I Screw Down | YES | YES | NO | NO | NO | NO | YES | YES | YES | YES |

| Snojax II Screw Down | YES | YES | NO | NO | NO | NO | NO | NO | NO | YES |

| Snojax II Glue Down | YES | YES | NO | NO | NO | NO | NO | NO | NO | YES |

| SnowBreaker 3M | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnowBreaker Screw Down | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnowCatcher | YES | YES | NO | NO | NO | NO | YES | YES | YES | YES |

| Decorative SnowCatcher | YES | YES | NO | NO | NO | NO | YES | YES | YES | YES |

| SnoCleat PBR | YES | YES | NO | NO | NO | YES | YES | YES | YES | YES |

| SnoCleat 2.67 | NO | YES | NO | YES | YES | NO | NO | NO | NO | NO |

| SnoBar PBR | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| ColorBar PBR | YES | YES | YES | NO | NO | YES | YES | YES | YES | YES |

| SnoBar 2.67 | NO | YES | NO | YES | YES | NO | NO | NO | NO | NO |

| ColorBar 2.67 | NO | YES | NO | YES | YES | NO | NO | NO | NO | NO |

Six Considerations Before Buying and Installing Snow Guards on MBCI Exposed Fastener Metal Roofing

1. Do I Need a Layout for My Snow Guards?

No matter the type of snow retention system you are installing, obtaining a design recommendation from the manufacturer is crucial. We offer complimentary spacing charts for our products on our website and free quote request forms for our snow rail systems and individual snow guards. These guides cater to customers who seek custom layout guidance. Installing snow retention solely in isolated areas, like just above doorways, HVAC systems, chimneys, etc., is not advisable, as these areas consistently pose a high risk of failure.

2. Do I Need to Screw Into Structure Under The Panel, or Will The Metal Panel Be Good Enough By Itself?

It is vital, when installing snow guards with mechanical fasteners, to make sure that you are screwing them into no less than 1" of wood structure, whether this is plywood decking, purlins, or blocking retrofitted behind each snow guard or bracket. Pre-engineered metal buildings should have snow guards mounted into metal purlins when possible. You should never install snow guards or rails using only the panel as the system's structure. Doing so has a very high risk of failure. Suppose the adequate structure is unavailable below the proposed snow guard mounting points, and the ground snow load is 45 psf or less. We recommend switching to a glue-down product if you cannot easily install additional blocking.

3. How Do I Avoid Roof Leaks?

When utilizing products such as the SnoCleat PBR, SnoCleat 2.67, SnowCatchers, or a screw-down rail system, they come equipped with butyl tape gaskets designed for sealing without liquid sealant. Coupled with screws featuring neoprene washers like our Master Grippers for wood or Master Drillers for metal, these components ensure a weather-tight seal. While it's not mandatory, some customers apply liquid silicone around these snow guards' perimeter for an additional protection layer. When fastening any of our polycarbonate snow guards to your roof with screws, it's crucial to use a neutral curing, cold-weather liquid silicone to seal the entire base effectively. Apply sufficient silicone over the whole base so that it oozes out around the edges, then run a gloved finger around the perimeter to complete the sealing process. Our recommendation for silicone sealant is the NovaFlex MR150, a product we have extensively compared and tested over the years. This experience leads us to endorse its effectiveness confidently. We advise using screws equipped with neoprene washers for these guards.

4. When Can I Install Glue Down Snow Guards?

Installing screw-down snow guards and rail systems is feasible throughout the year, provided the roof is clear of snow, ice, and debris. The timing, however, for installing glue-down snow guards requires careful consideration. SureBond SB-190, the standard adhesive for polycarbonate snow guard installation, requires approximately 28 days at 50 degrees Fahrenheit to cure fully. Late spring or early summer is optimal for customer installation in the USA and Canada. Although temperatures below 50 degrees won't damage the adhesive, they temporarily suspend the curing process until the temperature rises again. Rain won't negatively impact the glue after 24 hours. Additionally, it's important to note that using Surebond SB-190 adhesive with copper roofing should be avoided due to chemical reactions between the glue and metal.

5. What Is a Ground Snow Load?

The ground snow load is crucial in calculating the designed roof snow load for a particular location. Workers calculate this data from historical data collected from multiple weather stations across the United States. Contractors should only use glue-down and screw-down individual snow guards for projects with ground snow loads up to 45 pounds per square foot. Experts recommend snow rail systems for areas where ground snow loads exceed this threshold. Typically, a quick web search or examination of the building plans for your project will furnish you with the necessary ground snow load details. If assistance is required in locating this information, contacting your local building inspector or township office is advisable, as they will likely furnish you with this data.

6. Can I get my snow guards color-matched to my roof?

We offer color-matching solutions for all our metal snow guard options. The SnoCleat PBR, SnoCleat 2.67, and ColorBar Snow Rail Systems can incorporate slide-in color strips purchased with the guards or made by cutting leftover roofing material on-site. These slide-in strips easily match the faces of these products to your roof. Furthermore, we can customize the SnoCleat, SnoBar, ColorBar, and stainless steel SnowCatcher models with powder coating to achieve a comprehensive color match. Our capabilities extend to matching any roofing shade and crafting unique, bespoke colors for unconventional situations. Powder coating enables the snow guards to blend with the roofing panels seamlessly, enhancing the overall aesthetic of your residential, commercial, or industrial building. Please note that we do not stock powder-coated products in-house; we custom-make them upon order. Typical lead times for these orders are approximately 3–4 weeks. They may vary depending on the color and size of the order. In cases where customers require a quicker solution or prefer more direct control over the color, they can have their snow guards powder-coated locally or painted upon their arrival.

Conclusion

Selecting the appropriate snow guards for your project may appear overwhelming, but we hope this blog has offered valuable insights. Stay tuned as we add these featured blogs to more roof panel manufacturers. When purchasing snow guards, remember that a reputable company should readily address your inquiries and be able to offer guidance. SnoBlox-Snojax exemplifies this standard. For inquiries or orders, contact us at support@snojax.com or 1-800-766-5291. Explore our Snow Guard Buyer's Guide and What Works and What Doesn't page for additional details. Our team is committed to assisting you!

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.