Snow Guards For North Star Metals MFG Co Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jan 13th 2025

See the Snow Guards Compatibility Chart for North Star Metals Screw Down Metal Roofing Panels.

Are Snow Guards Necessary for North Star Metals Screw Down Steel Panels?

Winter poses significant challenges for buildings with exposed fastener metal roofs, primarily due to the risk of sudden snow and ice slides.

The smooth nature of these surfaces increases the likelihood of snow avalanches, which can pose serious threats to people, pets, and nearby property. We have developed specialized snow retention solutions for metal roofing to combat this issue. These innovative systems incorporate adjustable snow guards and rail systems designed to accommodate various metal roof configurations and effectively manage snow accumulation. When implementing these protective measures, it's essential to consider several key factors, including the roof's slope, panel configuration, and local weather patterns. We've made a range of educational resources available to assist property owners in making informed decisions. These include blog posts, informative web guides, and a comprehensive list of compatible metal panel manufacturers for snow retention solutions. Focusing on education and innovative approaches aims to mitigate the risks associated with snow and ice buildup, thereby creating safer environments in areas prone to heavy snowfall. These customized solutions effectively manage snow on metal roofs, provide peace of mind to property owners, and enhance safety for those in and around buildings with such roofing systems.

Exposed Fastener Metal Roof Panels by North Star

North Star Metals has established itself as a leading metal roofing and siding manufacturer since its inception in 1994. The company caters to diverse agricultural, architectural, industrial, and residential sectors. Advanced roll-forming and folding equipment enable them to produce custom panels and trims, driving their success accurately. This technological edge allows North Star Metals to create products ranging from a single inch to an impressive 53 feet long and even replicate discontinued items. Customer satisfaction is a core focus for North Star Metals. The company employs knowledgeable sales professionals proficient in specialized CAD software, ensuring precise project estimations. Their commitment to quality is evident in their meticulous packaging and delivery processes, with products carefully bundled and shielded from environmental factors. North Star Metals maintains its fleet of specially designed vehicles, including gooseneck trailers and crane-equipped semi-trailers, to guarantee efficient and secure transportation of materials. The company's dedication to continuous improvement in manufacturing techniques showcases its commitment to innovation and quality. This approach has cemented North Star Metals' reputation as a trusted partner in the metal industry. Combining extensive industry knowledge with cutting-edge technology, the company consistently delivers high-quality products tailored to meet each client's unique requirements.

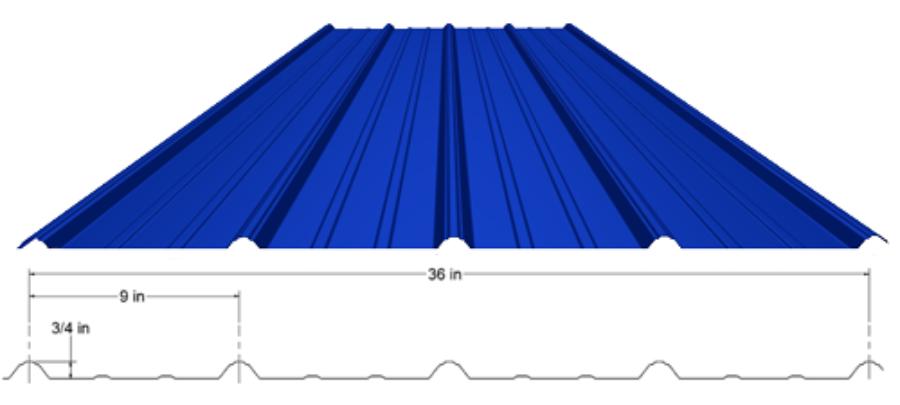

Five Star Panel

The Five Star Panel is a versatile metal roofing and siding solution. This steel panel features a sleek design with five main ribs, each 3/4 inch high and spaced 9 inches apart, covering 36 inches in width. Customizable up to 54 feet in length, it offers flexibility for various applications. The panel's durability is backed by impressive warranties, with 40 years for painted panels and 20 years for Galvalume Plus finishes. Suitable for residential, commercial, agricultural, and industrial settings, the Five Star Panel incorporates smart design elements for enhanced performance. An anti-siphon cavity in the purlin-bearing rib improves weather resistance by preventing water infiltration. The manufacturing process employs a unique pre-heated roll-forming technique, enhancing coating elasticity and adhesion while reducing micro-crazing and corrosion risks, thus extending the panel's lifespan. Customers can select from 18 vibrant, high-gloss colors treated with Valspar's Weather XL paint system, known for excellent color retention and gloss preservation. Some color options meet Energy Star standards, potentially qualifying for residential energy tax credits. With its durability, aesthetics, and practical design, the Five Star Panel is an excellent choice for those seeking a high-quality metal roofing or siding solution. See the Snow Guards Compatibility Chart for North Star Metals Five Star Screw Down Metal Roofing Panels.

The adaptable nature of this panel allows for integration with a range of our snow retention products, accommodating diverse installation requirements and material choices. You can fit products like SnoBlox Deuce and SnowBreaker models between the minor ribs for polycarbonate applications, the screw-mounted SnoCleat PBR, and various SnowCatcher designs. The 9-inch sections, which feature minor ribs, can be equipped with options like the mechanically fastened Snojax I or the versatile Icejax I. Customers can combine tall color brackets and suitable fasteners with aluminum ColorBar or galvanized SnoBar snow rail systems to create a comprehensive snow management system. This holistic approach results in a robust and efficient solution for managing snow buildup, ensuring reliable performance across various weather conditions and settings.

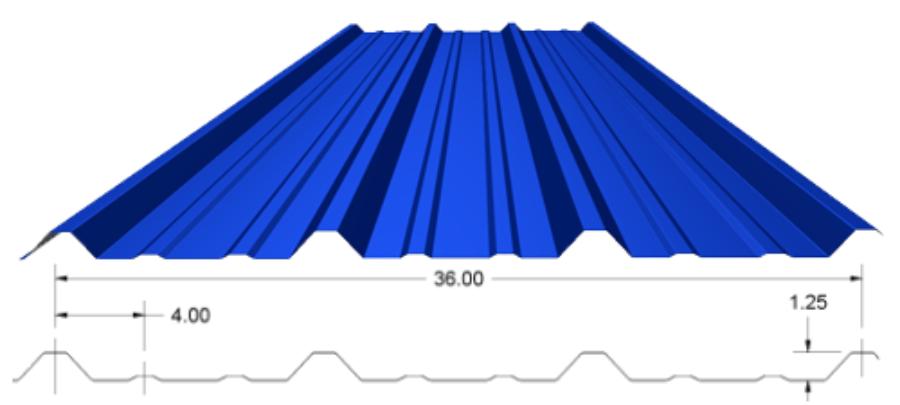

En-Dura Star Panel

The En-Dura Star Panel is a robust metal roofing and siding solution that excels in various applications. This heavy-profile panel features substantial ribs and deep channels, making it ideal for low-pitch roofing on commercial, industrial, and agricultural buildings. It also serves as an effective siding material. Its design incorporates four prominent ribs across a 36-inch coverage, with major ribs reaching 1-1/4 inches in height on 12" spacing. Dual stiffeners are positioned between these primary ribs to enhance rigidity. The panel is available in 24 and 26-gauge thicknesses, offering flexibility for different project needs. One of the key features of the En-Dura Star Panel is its deep channels, which facilitate efficient water drainage – a crucial aspect for low-pitch roofing applications. Weather-tight lap seals and a purlin bearing leg enhance the panel's weather resistance and provide additional structural support. The manufacturing process involves pre-heated roll-forming, which is said to improve the panel's durability by strengthening the elasticity of the galvanic coating's paint, primer, and zinc alloys. This technique produces more uniform adhesion and increased resistance to micro-crazing and corrosion. The manufacturer's confidence in the product's longevity is evident in the 40-year warranty offered with the En-Dura Star Panel. See the Snow Guards Compatibility Chart for North Star Metals En-Dura Star Screw Down Metal Roofing Panels.

The R-Panel panel system offers compatibility with our product options to meet diverse customer requirements, incorporating various models and designs. These comprehensive systems include screw-down alternatives like SnoBar and ColorBar rail systems and specialized solutions like SnoCleat PBR and stainless steel SnowCatcher designs. For the majority of polycarbonate snow guards, installation is typically recommended using screws or adhesives, with Surebond SB-190 being the preferred adhesive choice due to its exceptional bonding properties. However, it's important to note that this particular adhesive is unsuitable for metal pad-style guards. Proper placement is crucial for ensuring the optimal performance of the snow guard system. Installers should adhere to specific guidelines for different models during the installation process. Avoid attaching snow guards directly to the panel's high ribs, as this can compromise the stability and strength of the system. Instead, securing the snow guards through the panel's low flats into a solid underlying structure is the most effective method. This approach ensures a robust and reliable snow retention system capable of withstanding harsh winter conditions. By following these guidelines, installers can create an effective snow guard system that mitigates the potential hazards of snow and ice accumulation on roofs.

North Star Compatibility Chart for Snow Guards

| Five Star Panel | En-dura Star Panel | |

|---|---|---|

| IceJax I Screw Down | YES | YES |

| IceJax I Glue Down | YES | YES |

| IceJax II Screw Down | NO | YES |

| IceJax II Glue Down | NO | YES |

| SnoBlox Deuce Screw Down | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES |

| SnoBlox Ace Screw Down | NO | YES |

| SnoBlox Ace Glue Down | NO | YES |

| Snojax I Screw Down | YES | YES |

| Snojax II Screw Down | NO | YES |

| Snojax II Glue Down | NO | YES |

| SnowBreaker 3M | YES | YES |

| SnowBreaker Screw Down | YES | YES |

| SnowBreaker Glue Down | YES | YES |

| SnowCatcher | YES | YES |

| Decorative SnowCatcher | YES | YES |

| SnoCleat PBR | YES | YES |

| SnoCleat 2.67 | NO | NO |

| SnoBar PBR | YES | YES |

| ColorBar PBR | YES | YES |

| SnoBar 2.67 | NO | NO |

| ColorBar 2.67 | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by North Star

Assessing Snow Load Capacity

Review regional weather data and ground snow loads to determine your roof's ability to withstand snow accumulation. This insight will help you to select an appropriate snow retention mechanism. In areas with moderate snowfall, basic guards or rail attachments may suffice. Regions prone to heavy snow require more robust rail systems.

Ideal Installation Period

We recommend installation for North American adhesive-based snow guards in late spring or early summer. This timing allows proper adhesive setting, particularly for products requiring extended curing at specific temperatures. While rainfall isn't problematic after the initial setting, cold conditions can impede bonding. Our preferred adhesive, Surebond SB-190, requires approximately 28 days at 50 degrees or above to cure fully.

Handling Unique Roof Designs

Curved or non-standard roof panels pose distinct challenges for snow retention. Traditional flat-based guards may not adhere effectively to these surfaces. Explore specialized solutions designed for atypical roof shapes.

Strategic Placement Techniques

The arrangement of snow guards greatly influences their effectiveness. Avoid clustering guards in certain areas, which can lead to uneven weight distribution and potential system breakdown. Strive for a uniform layout across the entire roof. Use our snow guard spacing guide as reference.

Balancing Form and Function

Consider how snow retention systems impact your roof's visual appeal. Explore customizable options that complement your roof's aesthetics, such as color-coordinated components or professionally finished coatings. While DIY coloring is possible, professional treatments offer superior longevity and appearance.

Securing Proper Attachments

Robust anchoring is vital for mechanically mounted systems. Aim to fasten snow guards to a solid foundation, ideally using substantial wood decking or purlins. Direct attachment to metal supports is preferable to relying solely on the roof panel on metal roofs. Consider adhesive-mounted alternatives if reinforcing weaker structures isn't viable.

Waterproofing Considerations

Applying silicone sealant is crucial when installing screw-mounted polycarbonate snow guards. This practice ensures thorough coverage at the base and eliminates air pockets. While many metal components come with waterproof seals, some installers add extra sealant for enhanced protection, though this isn't always necessary.

Conclusion

SnoBlox-Snojax offers exceptional support for snow guard installations, focusing on durable, long-term solutions rather than quick fixes. Our primary objective is to ensure our customers understand our product range comprehensively. We combine personalized assistance with various resources, equipping our clients with the necessary knowledge and tools for successful implementation. Customers can use our services through direct engagement with our support team and our practical guides. At the heart of our mission lies an unwavering dedication to quality and practical effectiveness, reflecting our passion for product excellence and customer satisfaction. We have developed valuable resources such as a Snow Guard Buyer's Guide and a "What Works and What Doesn't" page to aid clients in making well-informed decisions. These materials offer crucial insights and practical information, simplifying the decision-making process. We actively encourage customers who need help with their orders to contact our support team via phone or email, ensuring they receive the guidance required to achieve the best possible results with our snow guard products.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.