Snow Guards For Standing Seam Metal Roof Panels by Chief Buildings

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Jun 21st 2024

See the Snow Guards Compatibility Chart for Chief Buildings Standing Seam Metal Roofing Panels.

"What Are the Best Snow Guards for Metal Roofs?"

When you have a standing seam metal roof with hidden fasteners on your residential, commercial, or industrial building, you must protect your property and its occupants from the dangers of snow and ice sliding off the roof. Due to their slippery nature, these roofing systems often require robust snow retention systems to withstand severe winter weather. This article explores various snow guard options compatible with standing seam metal roofs, such as those manufactured by Chief Buildings, helping you identify the most appropriate solution for your specific roofing system. As part of our ongoing educational blog post series, we'll highlight notable metal panel manufacturers and suggest suitable snow retention products. Our goal is to provide you with the knowledge needed to make informed choices that not only protect your investment but also ensure the safety of everyone during the challenging winter season. By understanding the available options and their compatibility with your roof, you can effectively mitigate the risks associated with snow and ice accumulation. This proactive approach will help safeguard your property, loved ones, and pets from potential hazards caused by sudden snow slides. Stay tuned as we delve into the world of snow retention systems, offering insights that will help you confidently navigate the complexities of winter roof safety.

Standing Seam Metal Roof Panels by Chief Buildings

Chief Buildings has been a cornerstone of the metal building industry for over six decades, evolving from humble beginnings in Grand Island, Nebraska, to become a multifaceted powerhouse in construction solutions. This family-owned enterprise has consistently adapted and expanded, leaving an indelible mark on the manufacturing, commercial, community, and agricultural sectors. The company's journey began in 1954 with Eihusen Construction Company's home remodeling projects, which later became Chief Construction. In 1959, the business diversified into grain bin manufacturing, establishing Big Chief of Nebraska, now known as Chief Agri in Kearney. A pivotal moment came in 1966 when the company entered the metal building manufacturing arena, giving birth to Chief Buildings. Throughout the years, Chief Industries - the company re-branded in 1968 - continued to expand its reach and capabilities. It established new facilities, including a grain bin plant in Rensselaer, Indiana, which later transitioned to producing metal buildings. The company's growth strategy included diversification into manufactured homes with BonnaVilla in Aurora, Nebraska, and the acquisition of Caldwell Manufacturing Company, enhancing its grain storage and aeration equipment offerings. The 1980s and 1990s saw further expansion and specialization. Chief Fabrication emerged as a separate entity in 1984, while Chief Buildings extended its manufacturing footprint with additional plants in Rensselaer, Indiana. The company also ventured into powder coating and structural steel fabrication, continuously broadening its expertise and services. In the new millennium, Chief Industries maintained its growth trajectory. It incorporated Chief Construction Company in Grand Island and established remote detailing and drafting locations in Lincoln, Nebraska, and Fort Dodge, Iowa. These strategic moves enhanced the company's design and construction capabilities. Recent years have been marked by significant milestones and continued expansion. Chief Industries celebrated its 65th anniversary in 2019, followed by Chief Buildings' 55th anniversary in 2021. In a testament to its ongoing growth, Chief Buildings opened its third manufacturing plant in Lancaster, South Carolina, in 2022, further solidifying its position as a leader in the metal building industry. This rich history showcases Chief Buildings' resilience, adaptability, and commitment to innovation, positioning it as a formidable force in the construction and manufacturing landscape.

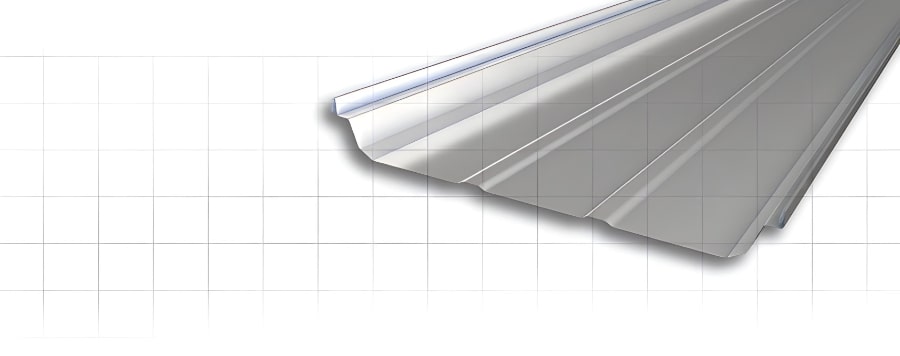

MSC Panel

Chief Buildings offers a robust standing seam roof system called the MSC (Mechanically Seamed Construction) panel. This innovative roofing solution combines durability, ease of installation, and aesthetic appeal. The panels, typically crafted from 24-gauge steel with a 22-gauge option for enhanced strength, feature a generous width of two feet (24"). Remarkably, these panels can be manufactured in lengths reaching up to 50 feet, significantly reducing the number of seams and potential weak points in the roofing system. The MSC panel's design incorporates a 3-inch-high standing seam, contributing to its structural integrity and ensuring excellent water drainage. One of the system's notable features is its versatility in terms of roof pitch. It can be effectively installed on slopes as minimal as 1/4:12, or 2%, making it suitable for various building designs. The panels are secured using a floating roof design with sliding clips, allowing for thermal expansion and contraction. This system and factory-applied hot-melt mastic for sealing produces a flexible, watertight roof. Chief Buildings has ensured that the MSC panel system is functional and customizable. It's available in various popular colors and three different paint systems, all applied over an acrylic-coated Galvalume base for enhanced durability. The MSC panel system's practical features and aesthetic options represent a comprehensive roofing solution for commercial and industrial applications. See the Snow Guards Compatibility Chart for Chief Buildings MSC Standing Seam Metal Roofing Panels.

This versatile panel integrates well with a wide array of snow retention solutions, ranging from adhesive-based polycarbonate snow guards to clamp-on systems. Its compatibility with larger polycarbonate options like IceJax II, Snojax II, and SnoBlox Ace, as well as smaller alternatives such as SnoBlox Deuce and IceJax I, ensures effective snow and ice retention on your roof. Additionally, the SnowBreaker and SnowBreaker 3M products facilitate safer snow and ice shedding by breaking the snowpack into smaller, more manageable pieces. Proper adhesive application with Surebond SB-190 for glue-down polycarbonate snow guards prevents moisture intrusion, refreezing, and detachment issues. A thicker application may be necessary to accommodate the panel's stiffening ribs, ensuring a secure and reliable installation. Furthermore, this panel is compatible with clamp-on snow guard systems such as SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These systems feature Standard SnoBar Clamps made from stainless steel or aluminum RoofClamps, complete with cupped-tip stainless steel set screws, providing a robust and reliable solution for snow retention.

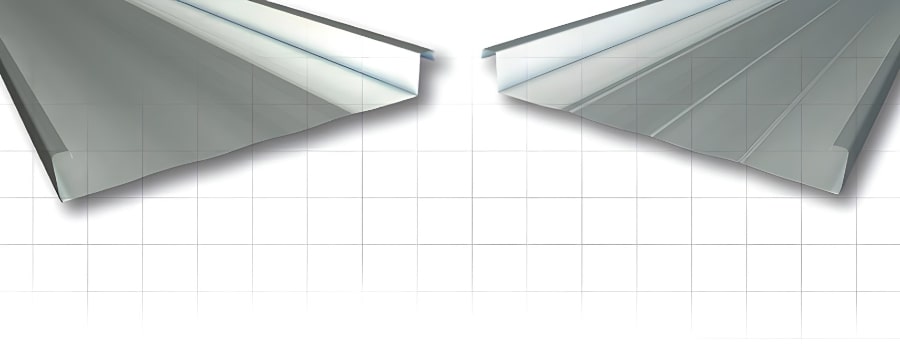

MVF/MVP Panel

The MVF (Mechanically Seam Vertical Leg Flat) and MVP (Mechanically Seamed Vertical Pencil-Rib) Panels by Chief Buildings are standing seam metal roofing systems that combine durability and aesthetic appeal. These mechanically seamed panels feature a seam height of 2 inches. Available in a 24-gauge steel option, the MVF/MVP Panels balance strength and lightweight construction. Rather than relying on traditional fastening methods, the MVF/MVP Panels utilize a clip fastening system. Specialized clips are installed on all purlins, securely holding the panels in place while contributing to the seamless and clean appearance of the roof. In addition to the panel itself, Chief Buildings offers a comprehensive range of accessories and components to complete the roofing system. The MVF/MVP Panels by Chief Buildings offer reliable and visually appealing options for standing seam metal roof applications across various projects. See the Snow Guards Compatibility Chart for Chief Buildings MVF/MVP Standing Seam Metal Roofing Panels.

These panels offer unparalleled versatility, integrating with a wide range of snow retention solutions to meet your needs. Whether you opt for adhesive-based polycarbonate snow guards or clamp-on systems, these panels deliver exceptional performance and reliability. For glue-down polycarbonate snow guards, such as IceJax II, Snojax II, SnoBlox Ace, SnoBlox Deuce, and IceJax I, proper adhesive application with Surebond SB-190 is crucial. This adhesive ensures a secure installation, preventing moisture intrusion, refreezing, and detachment issues. A thicker application may also be necessary to accommodate the panel's optional pencil ribs. The SnowBreaker and SnowBreaker 3M products function by breaking the snowpack into smaller, more manageable pieces, facilitating safer snow and ice shedding from your roof. For those seeking clamp-on solutions, this panel is compatible with systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These systems feature Standard SnoBar Clamps made from durable stainless steel or aluminum RoofClamps, complete with cupped-tip stainless steel set screws, ensuring a secure and long-lasting installation.

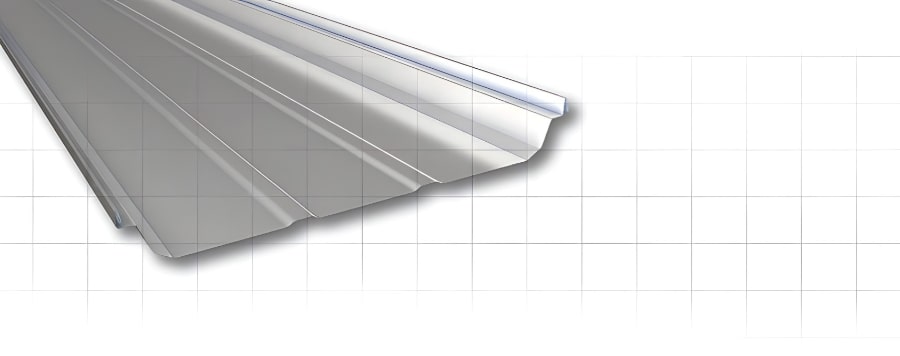

STC Panel

The STC metal roof panel, manufactured by Chief Buildings, is a standing seam roofing system designed for commercial and industrial structures. This panel features a width of 24 inches with a seam height of 3 inches. It is available in a 24-gauge Galvalume steel option, providing durability and corrosion resistance. The installation involves attaching the panels to the roof purlins using specialized clips, ensuring a secure and efficient installation. Additionally, the STC panel system offers compatibility with thermal spacers, enhancing the overall insulation performance of the roofing system. One of the notable features of the STC panel is its versatility in accommodating various roof details and transitions. The system includes pre-engineered components for eaves, gables, height changes, and other roof transitions, ensuring a seamless and professional finish. Complementing the STC panel, Chief Buildings offers a range of trim options, including pieces designed explicitly for eaves, gables, and other roof transitions. These trim pieces enhance the aesthetic appeal and contribute to the roofing system's overall functionality and weather resistance. While the STC panel shares similarities with the MSC panel, each panel type meets specific project requirements and design preferences. The STC panel is a robust and adaptable choice for those seeking a high-quality standing seam metal roof solution. See the Snow Guards Compatibility Chart for Chief Buildings STC Standing Seam Metal Roofing Panels.

Designed to accommodate a wide range of snow retention solutions, this panel offers unparalleled versatility and performance. Whether you prefer adhesive-based polycarbonate snow guards or clamp-on systems, this panel delivers exceptional results. For glue-down polycarbonate snow guards, such as the larger IceJax II, Snojax II, and SnoBlox Ace, or the smaller SnoBlox Deuce and IceJax I, proper adhesive application with Surebond SB-190 is crucial. Proper adhesive application ensures a secure installation, preventing moisture intrusion, refreezing, and detachment issues. A thicker application may also be necessary to accommodate the panel's stiffening ribs, further enhancing the installation's reliability. The SnowBreaker and SnowBreaker 3M products offer an added layer of safety by breaking the snowpack into smaller, more manageable pieces, facilitating safer snow and ice shedding from your roof. For those seeking clamp-on solutions, this panel is compatible with systems like SnoCleat RC, SnoCleat RCT, SnoBar, and ColorBar. These systems feature Standard SnoBar Clamps made from durable stainless steel or aluminum RoofClamps, complete with cupped-tip stainless steel set screws, ensuring a secure and long-lasting installation.

Chief Buildings Compatibility Chart for Snow Guards

| MSC Profile | MVF/MVP Profile | STC Profile | |

|---|---|---|---|

| IceJax I Glue Down | YES | YES | YES |

| IceJax II Glue Down | YES | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES |

| SnoBlox Ace Glue Down | YES | YES | YES |

| Snojax II Glue Down | YES | YES | YES |

| SnowBreaker Glue Down | YES | YES | YES |

| SnowBreaker 3M | YES | YES | YES |

| SnoBar Standing Seam | YES | YES | YES |

| ColorBar Standing Seam | YES | YES | YES |

| SnoBar RCB-3 | YES | YES | YES |

| ColorBar RCB-3 | YES | YES | YES |

| SnoBar 2-Bar | YES | YES | YES |

| ColorBar 2-Bar | YES | YES | YES |

| SnoCleat RC | YES | YES | YES |

| SnoCleat RCT | YES | YES | YES |

Ensuring Optimal Snow Guard Performance on Chief Buildings Standing Seam Roofs

Timing Is Everything for Adhesive-Mounted Snow Guards

When it comes to adhesive-mounted polycarbonate snow guards, installation timing is crucial. The industry-standard Surebond SB-190 adhesive requires about a month at 50°F to fully set. Twenty-eight days, to be exact. Plan these installations for optimal results in North America during late spring or early summer. While rain won't affect the adhesive after about a day, it's important to note that SB-190 isn't suitable for copper roofs due to potential chemical reactions leading to early corrosion.

Enhance Protection with IceStoppers

For standing seam roofs using SnoBar or ColorBar systems, consider adding IceStopper attachments. These are particularly beneficial over high-traffic areas like walkways and entrances. You can install them during the initial setup or retrofit them later. Proper spacing is vital, especially for seams taller than 1 inch, as ice can slip under the bar without IceStoppers.

Avoid Screwing into Standing Seam Roofs

Never screw snow guards or rails directly into standing seam metal roofs. Due to the roof's natural expansion and contraction, this improper method can lead to panel damage, leaks, costly repairs, and voided warranties. Instead, opt for clamp-on or adhesive-mounted systems to ensure compatibility and security.

Understand Your Local Ground Snow Load

Knowing your area's typical snow accumulation, or "Ground Snow Load," is essential when selecting snow retention systems for metal roofs. Most individual pad-style snow guard systems can handle up to 45 pounds per square foot (psf) without issues. For areas with heavier snowfall, more robust snow rails are necessary. If your roof panels aren't compatible with snow rails and your ground snow load exceeds 45 psf, consult the panel manufacturer for recommendations. A quick online search for "[your town] ground snow load" should provide local data.

Design an Effective Layout

A successful snow retention system should span the entire roof length, typically with multiple ascending rows to distribute weight evenly. Install individual guards in a staggered pattern and mount rails in straight lines. Avoid isolated installations that can overload the system. For SnowBreaker systems, follow the manufacturer's specific placement guidelines if you want an isolated installation. The SnowBreaker has a different rule set as its purpose isn't to hold snow and ice on the roof. Please use our free resources, spacing charts, and custom quote request forms for optimal layout design.

Test for a Perfect Fit

Before committing to a snow retention system, verify that the snow guards, clamps, brackets, or IceStoppers fit your project correctly. You can order individual samples and kits, such as 20" and 27" bar samples, without minimum order requirements. This step ensures a perfect fit and helps avoid costly mistakes.

Coordinate Colors for Style

For a sleek, cohesive look, you can match the color of your metal snow retention system to your roof. Some systems, like our SnoCleats and ColorBar rail systems, feature interchangeable slide-in metal strips that can be color-matched. Alternatively, some customers use contrasting colors to add visual interest. You can purchase these strips with the system or create them on-site using leftover roofing material. Custom powder coating is also available for an additional fee to seamlessly blend the system with your roof color.

Conclusion

At SnoBlox-Snojax, we're dedicated to making your snow guard selection and installation journey seamless and rewarding. Our expert team is always ready to lend a helping hand with any queries you might have. Feel free to reach out to us via email at support@snojax.com or give us a call at 1-800-766-5291. We believe in empowering customers with knowledge. That's why we've developed a range of invaluable resources for your benefit. Our comprehensive Snow Guard Buyer's Guide offers insights to help you make well-informed decisions. Our "What Works and Doesn't" page provides essential perspectives on best practices and potential challenges, ensuring your installation process is smooth and successful. We encourage you to take full advantage of these resources. With SnoBlox-Snojax, you're not just buying a product but gaining a partner in your snow protection journey.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.