Snow Guards For Whirlwind Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Mar 10th 2025

See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components Exposed Fastener Metal Roofing Panels.

Why Are Snow Guards Necessary for Whirlwind Steel Buildings Screw Down Metal Roofs?

As winter descends, buildings with exposed fastener metal roofs face unique challenges, particularly the risk of sudden snow and ice slides.

The smooth nature of these roofs increases the potential for snow avalanches, which can be hazardous to people, pets, and property. We have developed specialized snow retention systems for metal roofs to address this issue. These innovative solutions, including snow guards and adaptable rail configurations, can be customized to suit various roof designs and effectively manage snow buildup. When implementing these systems, it's crucial to consider several factors, such as the roof's slope, panel layout, and local weather conditions. To assist in making informed decisions, we have created various educational resources, including our informative blog posts, comprehensive online guides, and up-to-date lists of compatible metal panel manufacturers and their products. These snow retention solutions mitigate the risks associated with snow and ice accumulation in areas prone to heavy snowfall. Enhancing safety and providing greater confidence in roofing systems offer peace of mind throughout the challenging winter.

Exposed Fastener Metal Roof Panels by Whirlwind

Whirlwind Steel Buildings & Components has been a key player in the metal building industry since its establishment in Houston, Texas, in 1955. The company, founded by C.O. Sturdivant, initially produced attic fans before diversifying into metal building components in the early 1960s. A significant expansion occurred in 1966 when Whirlwind Steel began designing and manufacturing pre-engineered building systems, marking a crucial turning point in its development. Over time, the company has grown into a comprehensive provider of metal building solutions, offering various products, including pre-engineered structures, panels, framing components, roofing systems, and multiple accessories. Whirlwind Steel now operates two large manufacturing facilities, one in Houston and another in Tallapoosa, Georgia, each covering 250,000 square feet. This extensive manufacturing capacity has enabled the company to complete more than 200,000 projects across all 50 U.S. states and internationally, cementing its position as an industry leader. At the core of Whirlwind Steel's operations are quality and innovation. The company rigorously tests its products for various environmental factors, including hail impact, fire resistance, wind-driven rain, snow loads, and high-velocity winds. Their commitment to quality is further evidenced by the extensive warranties offered on their products, some lasting up to 40 years. Currently led by President Ty Sturdivant, alongside Jack Sturdivant, Whirlwind Steel remains a family-owned business in its third generation. The company upholds core values, prioritizing relationships, purposeful action, passion, innovation, excellence, and customer satisfaction.

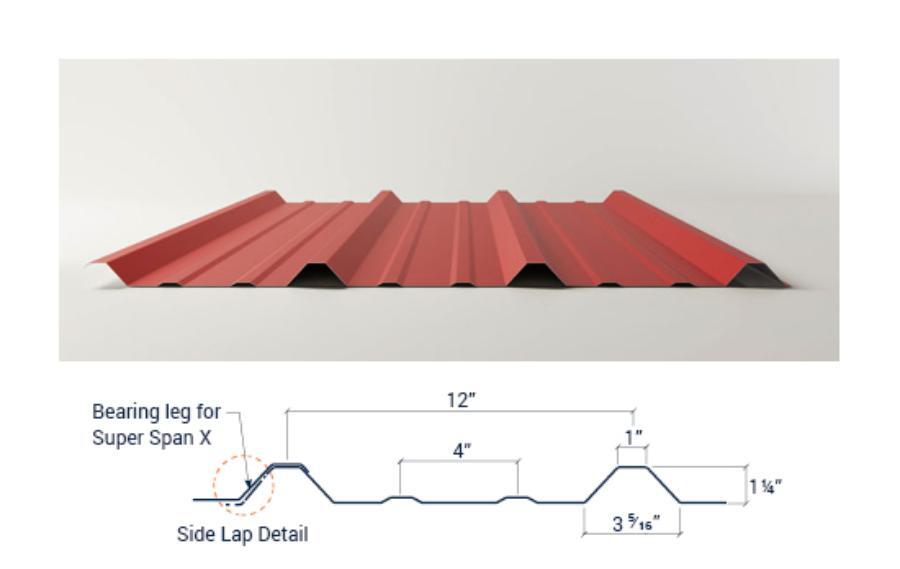

Super Span X

Whirlwind Steel Buildings offers a popular and versatile metal roofing solution, the Super Span X panel. This cost-effective option serves roofing and wall applications, lending a classic appearance to construction projects. The Super Span X features an exposed fastener design and comes in various steel gauges, including 26, 24, and 22. It boasts several important certifications, such as UL Construction ratings, UL 580 Up-Lift testing with a Class 90 rating, and UL 2218 Hail Impact Resistance testing, achieving Class 4 for sloped surfaces. The panel's design incorporates a 36-inch coverage width with ribs measuring 1¼ inches in height, spaced 12 inches apart. This configuration is commonly called a PBR panel in the construction industry. The Super Span X has also earned approvals from regulatory bodies like the Texas Department of Insurance and Florida Product Approval and has a Dade County Notice of Acceptance (NOA). Performance capabilities of the Super Span X vary depending on the chosen gauge and span configuration. For instance, a 26 gauge panel with 80 KSI steel strength in a single span setup can resist negative wind loads ranging from 127.6 psf at a 3-foot span to 11.2 psf at a 7-foot span. These characteristics make the Super Span X attractive for builders seeking strength, performance, and visual appeal in their metal roofing and wall cladding solutions. See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components Super Span X Exposed Fastener Metal Roofing Panels.

This panel design offers remarkable versatility for snow guard installation, catering to various project needs and preferences. It can accommodate multiple snow guard types, from screw-fastened rail systems to stainless steel SnowCatchers. Most polycarbonate snow guard models are compatible with adhesive and screw-down installation methods, except for the Snojax I, which requires screw-down installation exclusively. Installers should position smaller snow guards between the minor ribs in the panel's center for optimal performance. However, certain models like the Snojax II and Icejax II must be placed off-center, consistently straddling either the left or right minor ribs or mesas. It's crucial to avoid attaching snow guards or rail systems directly to the panel's high ribs. Instead, mount them through the low, flat sections of the panel for maximum stability and strength into a solid underlying structure. When using adhesive for polycarbonate models, it's essential to use the industry-standard Surebond SB-190 adhesive. However, this particular adhesive is not suitable for metal pad-style snow guards. By adhering to these guidelines, installers can ensure effective and long-lasting snow guard installations on these adaptable panels, providing reliable protection against snow and ice buildup.

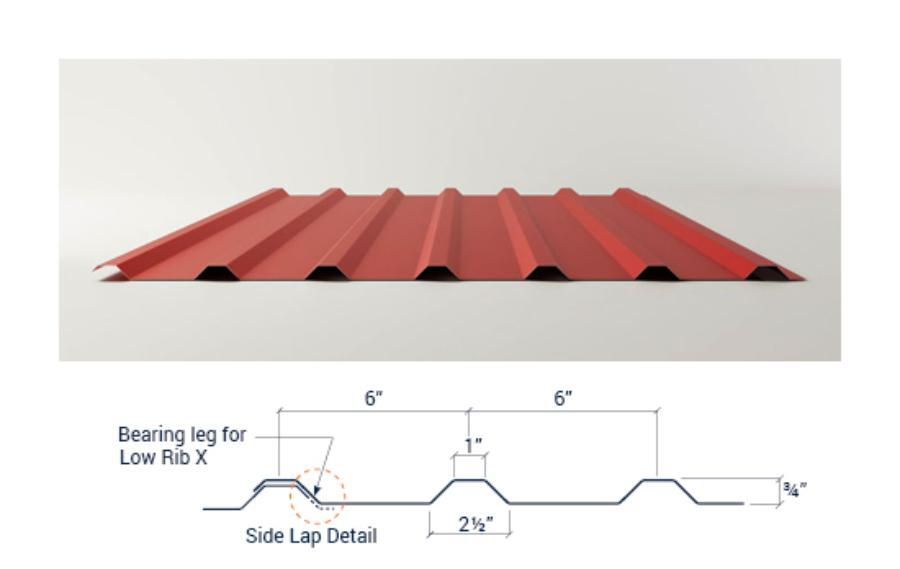

Low Rib X

The Low Rib X panel is a versatile metal component for roofing and wall construction applications. This exposed fastener panel boasts a coverage width of 36 inches, with ribs that stand 3/4 inches high and 6 inches apart from center to center. Known for its durability, the Low Rib X panel has impressive warranty options extending up to four decades. Customers can choose between 22, 24, and 26-gauge panel versions, with the latter offering enhanced resistance to wind loads. The panel is crafted from Galvalume-coated steel, adhering to ASTM A792 standards and boasting a Grade 80 classification with a minimum yield strength of 80,000 psi. For those seeking additional protection and aesthetic appeal, a Kynar 500 Fluoropolymer finish coating is available. Whirlwind has designed the Low Rib X panel as part of a comprehensive building solution. To this end, they offer a complete range of compatible trim, hardware, and accessories. This integrated approach, combined with the panel's adaptability and long-term warranty, has made the Low Rib X a favored choice across a wide spectrum of metal building projects. See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components Low Rib X Exposed Fastener Metal Roofing Panels.

The Low Rib X panel presents a unique set of challenges for snow retention systems due to its distinctive narrow and flat areas, which measure about 3 1/2 inches in width. However, this doesn't mean effective options for managing snow and ice accumulation on these roofs aren't available. We recommend the Ace, Deuce, or Icejax I models for those prioritizing secure retention. At the same time, individual polycarbonate snow guard pads are also excellent for snow retention. Alternatively, the SnowBreaker and SnowBreaker 3M models are ideal for controlling snow-shedding and releasing snow and ice in smaller, less dangerous amounts. A key advantage of all these models is their installation flexibility, as they can be mounted using either screws or Surebond SB-190 adhesive. This versatility ensures property owners can choose the best method that suits their needs and preferences. For those who prefer a bar-style approach to snow retention, the Low Rib X panel is compatible with tall ColorBrackets, which allow for the mechanical attachment of SnoBar and ColorBar systems. This compatibility provides another option for effectively managing snow and ice on these challenging roof panels, ensuring that property owners have a range of solutions based on their specific requirements and preferences.

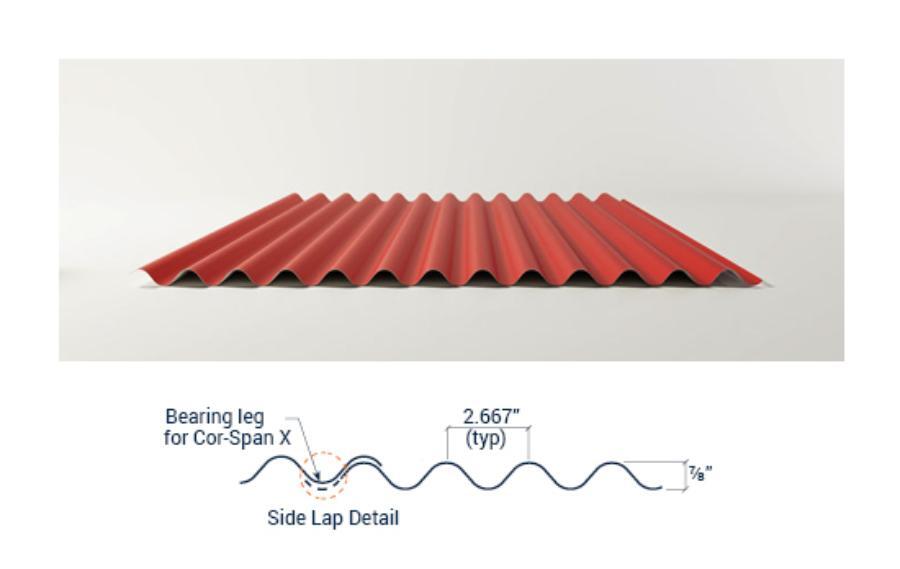

Cor Span X

The Cor Span X metal roof panel is a versatile corrugated panel designed for various commercial, industrial, and agricultural applications. This panel boasts a coverage width of 32 inches and a continuous wave pattern with a rib height of 7/8 inches. Available in 22, 24, and 26 gauge steel, the Cor Span X is crafted from Steel Grade 80/D, adhering to ASTM A-792 standards, and offers a minimum yield strength of 60 ksi. The panel's design incorporates a bearing leg for enhanced support during installation and can be used on roof slopes as low as 1:12. One of the key features of the Cor Span X is its ability to span greater distances between support members, potentially reducing overall project costs and installation time. The panel can be manufactured up to 40 feet long, with longer options available upon request. Its exposed fastening system typically employs #10-12 x 1-1/4 inch screws, contributing to its ease of installation. The Cor Span X has undergone rigorous testing and has received several important certifications, including UL 2218 for hail impact resistance and approval from the Texas Department of Insurance. Whirlwind offers the Cor Span X with a GALVALUME® coating, providing excellent corrosion resistance. Additionally, customers can choose from a range of color options with either SMP (Silicone-Modified Polyester) or Kynar 500® finishes, allowing for customization to suit various architectural styles and project requirements. This combination of structural integrity, versatility, and aesthetic options makes the Cor Span X a popular choice for a wide range of roofing projects in the commercial and industrial sectors. See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components Cor Span X Exposed Fastener Metal Roofing Panels.

The Cor Span X Corrugated Panel stands out in the world of exposed fastener roofing with its distinctive wavy corrugated design. This unique feature allows for an unconventional approach to snow guard installation, permitting mounting on the panel's high ribs, which is typically not recommended for other exposed fastener roofing types. The Cor Span X Panel offers compatible options for snow retention systems. A recent addition to these options is the SnoCleat 2.67 snow guard, which can be securely fastened to the panel's high ribs using 3-inch screws. Customers also have the choice of SnoBar or ColorBar systems, which utilize the ColorBracket 2.67, the same bracket used in the SnoCleat 2.67 system. The ColorBracket 2.67 is designed with six attachment holes, providing installation flexibility. While four screws per bracket are generally sufficient, utilize all six holes for increased mounting strength, which is particularly beneficial in regions prone to severe weather conditions.

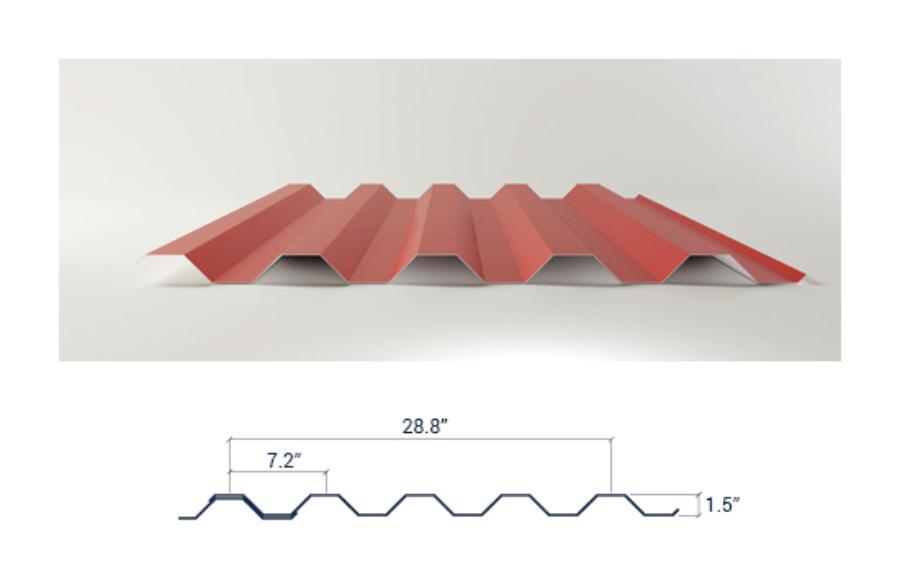

7.2N Rib

The 7.2N Rib panel is a versatile, durable metal roofing and wall panel option, ideal for commercial and residential applications. With a coverage width of 28.8 inches and rib spacing of 7.2 inches, this panel features a rib height of 1½ inches that enhances structural integrity and effectively channels water, making it suitable for areas with heavy rainfall. Available in multiple gauge options—26, 24, and 22 gauge—this panel caters to varying project requirements, with the 22 gauge providing maximum durability for extreme weather conditions. Whirlwind offers a wide range of color options and high-performance paint finishes that resist fading, chalking, and corrosion, ensuring long-lasting beauty. They rigorously tested the panel, achieving UL 580 Class 90 uplift rating for wind resistance, UL 2218 Class 4 hail impact resistance, and Florida Product Approval for harsh coastal environments. Installation is straightforward, with options for exposed or concealed fasteners, allowing flexibility based on aesthetic preferences and performance needs. Overall, the 7.2N Rib panel combines strength, durability, and aesthetic appeal, making it a preferred choice across various construction industry sectors. See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components 7.2N Rib Exposed Fastener Metal Roofing Panels.

The 7.2 Panel offers versatile snow and ice management options for your roof. Installers can combine it with various products designed to handle winter precipitation effectively. One such product is the polycarbonate SnoBlox Deuce, a pad-style guard that helps retain snow and ice on the roof. Another option is the SnowBreaker, which breaks down snow and ice into smaller, more manageable pieces as they slide off the roof, enhancing safety. These snow guards are designed for easy installation, offering both screw and adhesive mounting options. The SnowBreaker 3M variant even allows for 3M double-sided tape installation. For those preferring a rail system, the 7.2 Panel is compatible with the galvanized SnoBar and the aluminum ColorBar. These rail systems are securely attached using the 1.5-inch wide aluminum Tall ColorBracket, ensuring a robust and efficient snow management solution for your roofing needs.

Sturdi-Rib

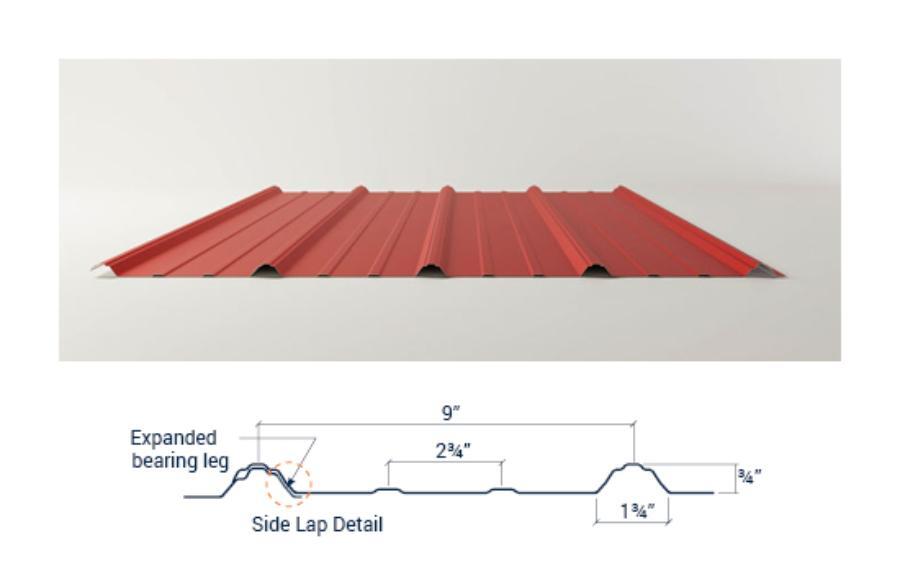

The Sturdi-Rib Metal Roof Panel by Whirlwind is a versatile, durable roofing option. It features a 36 inch maximum coverage width with major ribs spaced at 9 inches on-center and a rib height of 3/4 inch. They designed this panel for non-structural applications, typically installed over 15/32 inch APA-rated plywood decking. The Sturdi-Rib panel is available in 24 and 26-gauge options, providing flexibility for different project requirements. This panel's design allows for excellent performance in various weather conditions, with allowable design uplift pressures ranging from 52.5 psf to 138.5 psf, depending on the fastener pattern and spacing. See the Snow Guards Compatibility Chart for Whirlwind Steel Buildings & Components Sturdi-Rib Exposed Fastener Metal Roofing Panels.

The Sturdi-Rib Panel is compatible with an array of our snow retention solutions. For those who favor polycarbonate, the SnoBlox Deuce and SnowBreaker models are recommended, with placement options in the center flat spaces between the minor ribs. Metal enthusiasts can opt for screw-mounted products like the SnoCleat PBR or choose from six distinct SnowCatcher designs installed in the panel's central flat area. Spanning the minor ribs between 9 inch sections, the Snojax I and Icejax I offer additional alternatives. While the Snojax I requires mechanical fastening, the Icejax I provides both adhesive and screw mounting options. For a more comprehensive snow management approach, the Sturdi-Rib can be combined with Tall ColorBrackets and suitable fasteners to support either aluminum ColorBar PBR or galvanized SnoBar PBR snow rail systems. This integrated strategy ensures effective and dependable snow accumulation management, delivering optimal performance across various weather conditions and environmental settings. By offering such a diverse selection of products and installation methods, the Sturdi-Rib Panel system allows for customized solutions that meet the specific needs of each project, ultimately providing peace of mind and protection against potential snow-related hazards.

Whirlwind Compatibility Chart for Snow Guards

| Super Span X | Low Rib X | Cor Span X | 7.2N Rib | Sturdi-Rib | |

|---|---|---|---|---|---|

| IceJax I Screw Down | YES | YES | NO | NO | YES |

| IceJax I Glue Down | YES | YES | NO | NO | YES |

| IceJax II Screw Down | YES | NO | NO | NO | NO |

| IceJax II Glue Down | YES | NO | NO | NO | NO |

| SnoBlox Deuce Screw Down | YES | YES | NO | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES | NO | YES | YES |

| SnoBlox Ace Screw Down | YES | YES | NO | NO | NO |

| SnoBlox Ace Glue Down | YES | YES | NO | NO | NO |

| Snojax I Screw Down | YES | NO | NO | NO | YES |

| Snojax II Screw Down | YES | NO | NO | NO | NO |

| Snojax II Glue Down | YES | NO | NO | NO | NO |

| SnowBreaker 3M | YES | YES | NO | YES | YES |

| SnowBreaker Screw Down | YES | YES | NO | YES | YES |

| SnowBreaker Glue Down | YES | YES | NO | YES | YES |

| SnowCatcher | YES | NO | NO | NO | YES |

| Decorative SnowCatcher | YES | NO | NO | NO | YES |

| SnoCleat PBR | YES | YES | NO | NO | YES |

| SnoCleat 2.67 | NO | NO | YES | NO | NO |

| SnoBar PBR | YES | YES | NO | YES | YES |

| ColorBar PBR | YES | YES | NO | YES | YES |

| SnoBar 2.67 | NO | NO | YES | NO | NO |

| ColorBar 2.67 | NO | NO | YES | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Whirlwind

Customizing Snow Management for Diverse Roof Materials

Adapting snow retention techniques is crucial for different roofing materials. Softer metals like aluminum or copper may require more closely spaced rows than sturdier steel roofing with clamp-on systems.

Tackling the Challenges of Curved Roofs

Curved roofs present unique difficulties for snow retention. Traditional flat guards often necessitate creative solutions from roofing professionals to manage snow on these architecturally distinctive surfaces effectively.

Integrating Ice Prevention Measures

Consider incorporating specialized components such as our IceStoppers into your retention system in areas prone to ice formation. Careful selection and placement of these elements is particularly important for roofs with higher seams to combat ice-related problems effectively.

Harmonizing Function with Visual Appeal

Select snow retention systems that enhance rather than detract from your roof's appearance. Options range from color-matched guards to those with coordinating metal inserts. Local coating and painting services or DIY coloring methods can also achieve a cohesive look for cost-conscious homeowners.

Assessing Regional Snowfall Patterns

When selecting a snow retention system, factor in your area's typical winter weather and ground snow load. Simple pad-style guards may suffice in regions with light snowfall (under 45psf). In contrast, areas prone to heavy accumulation (over 45psf) require more robust rail systems to prevent dangerous snow slides.

Developing a Holistic Roof Protection Plan

Create a comprehensive strategy to safeguard your entire roof structure. This approach distributes multiple rows of retention devices to disperse snow loads evenly. Utilize spacing guidelines and specialized tools to optimize placement for maximum effectiveness.

Ensuring System Compatibility

Before installation, thoroughly evaluate the compatibility of all system parts with your specific roof type. This critical step prevents costly mistakes and ensures seamless integration. Consider testing individual components to guarantee a perfect fit.

Navigating Copper Roof Installations with Care

Exercise particular caution when installing retention systems on copper roofs. Avoid direct contact between certain adhesives and copper surfaces to prevent chemical reactions. For bar systems, protective coatings can mitigate interactions between dissimilar metals.

Optimizing Adhesive Applications

Plan adhesive-mounted installations during appropriate weather windows. Consider temperature variations when estimating curing times, noting that high-quality adhesives may require extended bonding periods in moderate conditions.

Conclusion

SnoBlox-Snojax prioritizes providing comprehensive support for snow guard installations, emphasizing durable and effective solutions over quick fixes. The company's primary goal is to ensure customers fully understand their product range through personalized assistance and various informative resources. Whether clients require direct support or practical guides, our team equips them with the necessary knowledge and tools for successful installations. SnoBlox-Snojax offers valuable resources such as a Snow Guard Buyer's Guide and a What Works and What Doesn't page to aid decision-making. These materials provide crucial information and insights, simplifying the customer selection process. For those needing assistance with orders, the company encourages contacting their support team via phone or email, where expert guidance is readily available to ensure optimal results. SnoBlox-Snojax empowers customers to make informed decisions and successfully implement their snow guard solutions by combining professional support, educational materials, and an unwavering dedication to quality.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.