Snow Guards For Exposed Fastener Roof Panels by ATAS International, Inc.

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Apr 19th 2024

See the Snow Guards Compatibility Chart for Atas Metal Roofing Panels.

Choosing snow guards is crucial when protecting your home or building with an exposed fastener metal roof. Different metal roof panel profiles require specific snow guard solutions to manage snow and ice effectively. In this blog, we'll explore the various snow guard options available for ATAS International's exposed fastener metal roofs, guiding you toward selecting the right product for your roof system. This blog series aims to continue highlighting prominent metal panel manufacturers and offering recommendations for compatible snow guard solutions, empowering customers to navigate this process confidently.

Snow Guards For Exposed Fastener ATAS International, Inc. Metal Roofing

ATAS International is a family-owned metal manufacturing company that has experienced remarkable growth over the past six decades. The company, founded in 1963 in New York by Jacobus Bus, initially specialized in supplying construction materials. Under the leadership of his sons, Dick and Jim, ATAS has expanded its operations and product offerings significantly. With facilities across multiple states, ATAS manufactures a wide range of metal building materials, including wall cladding, roofing, and ceilings. The organization has garnered acclaim as a premier workplace, underscoring its dedication to its workforce. The next generation of the Bus family has taken on active roles, ensuring the continuation of the family's legacy. ATAS has maintained its focus on quality and customer service throughout its evolution, cementing its reputation as an industry leader in the metal manufacturing sector.

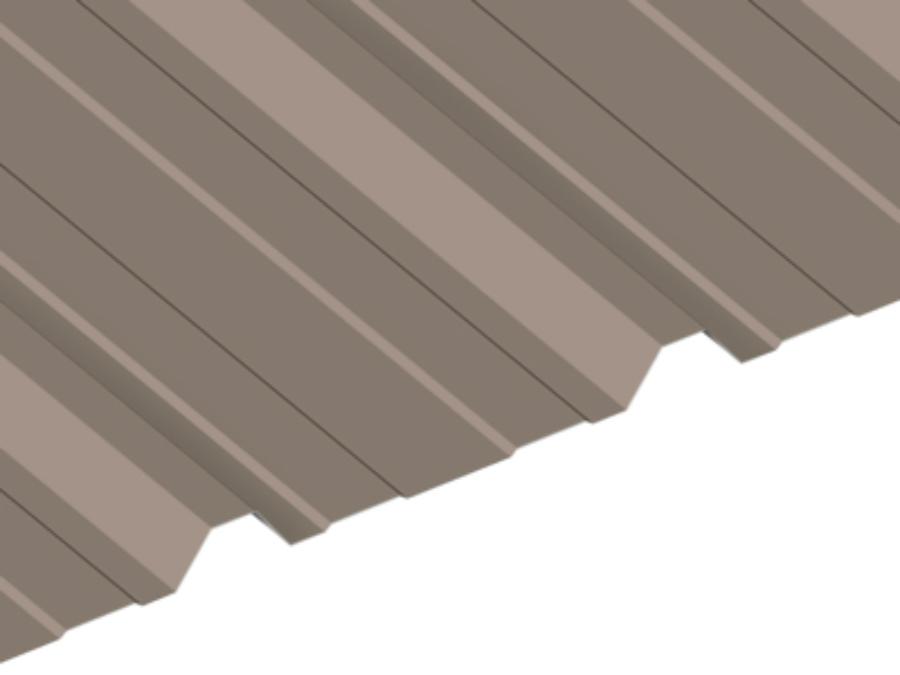

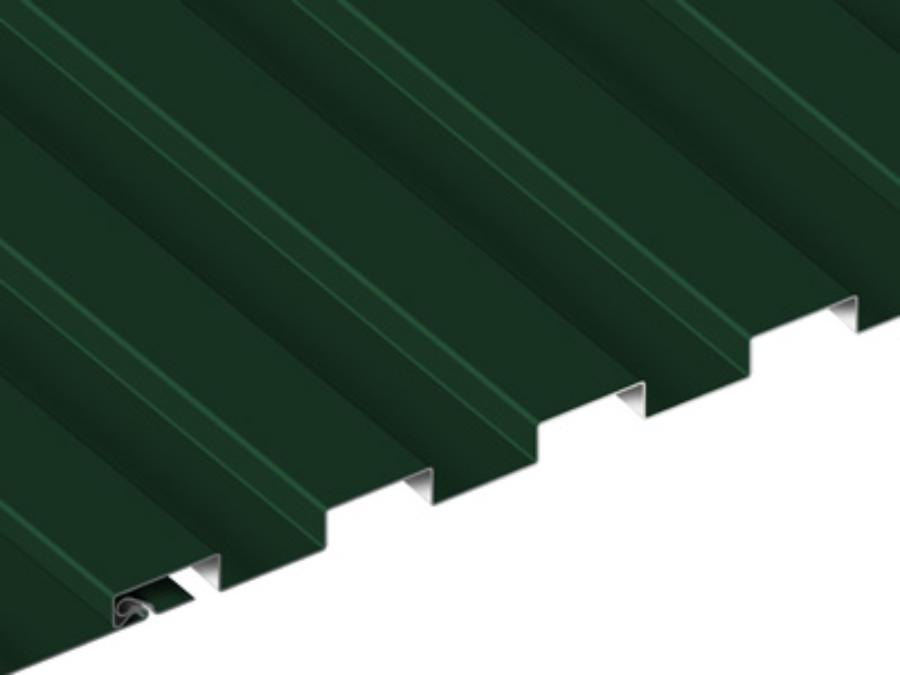

Belvedere Grand R Metal Panels

The Belvedere Grand R Metal Panel is versatile for wall and roof applications. These structural metal panels are available in various materials, including aluminum, metallic-coated steel, and zinc. The panels feature an overall coverage width of 39 inches and 1.5-inch tall major ribs spaced 13 inches apart, which is a unique design compared to a standard 12-inch R Panel. The Belvedere Grand R Panels are designed for installation using exposed fasteners and can be oriented vertically or horizontally. They meet various industry standards, including ASTM UL, A792, A653, B209, B370, and A755, ensuring they adhere to rigorous performance and safety requirements. See the Snow Guards Compatibility Chart for Atas Belvedere Grand R-Panel Metal Roofing Panels.

Additionally, the panels are impact-rated, hail-resistant, and contain 55% recycled content, making them an environmentally-conscious choice. With their abrasion-resistant and easy-maintenance properties, these panels provide a durable and versatile solution for wall and roof applications across various commercial and residential projects. The Belvedere Grand R Panels require a minimum slope of 1.5:12.

The Belvedere Grand R Metal Panels are compatible with multiple snow guard options, though not as many as traditional R-Panel designs. These panels are compatible with the screw-down SnoBar and ColorBar, as well as the SnoCleat PBR and stainless steel SnowCatcher models, including the Standard Rectangle, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak designs. Regarding the attachment of polycarbonate snow guards, this panel does not feature the same kind of minor rib pattern found on most PBR and R-Panel roofs. As such, we recommend only snow guards mounted in the centers of the panel, such as the SnoBlox Deuce and Ace, for customers wanting to hold the snow and ice on their roofs. Customers who desire snow and ice to be shed from their roofs, albeit more safely, can use SnowBreaker or SnowBreaker 3M to achieve this goal. These recommended polycarbonate snow guards can be attached to this panel using either adhesive or screws. Surebond SB-190, the industry standard for snow guard adhesive, must be used only for polycarbonate models, as it is incompatible with metal pad-style snow guards. It is also essential to avoid screwing individual pad-style snow guards or rail systems onto the high ribs of the panel and instead secure them by screwing down through the panel's low flats into a solid structure to achieve the best installation strength.

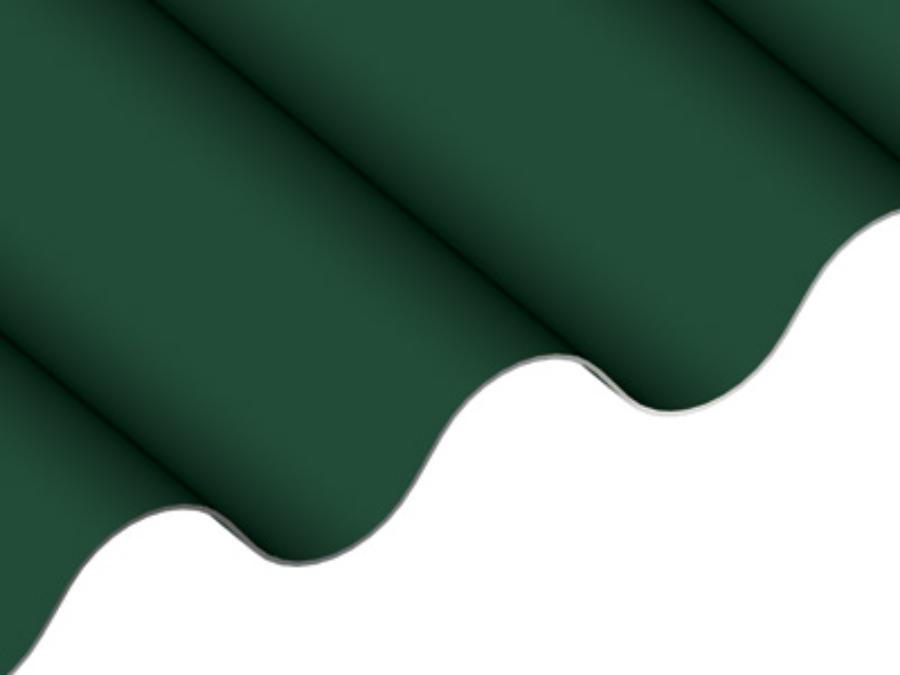

Corrugated Metal Panels

Corrugated metal panels are popular for wall and roof applications, offering a traditional and economical option. These panels are available in various materials, including aluminum, metallic-coated steel, 55% Al-Zn alloy-coated steel, copper, and zinc. The standard panel width is 37.25 inches, and it comes in a wide range of material thicknesses depending on the style you select. These panels feature a corrugation depth of inches and rib spacing of 2.6875 inches on-center. The minimum recommended slope for roof installations is 3:12. You can install the panels horizontally or vertically with exposed fasteners. Corrugated metal panels are available in a smooth or stucco-embossed texture and come in over 40 stock colors, with custom colors and finishes also available. Typical applications for these panels include walls, mansards, and equipment screens, providing a traditional and economical metal cladding solution. See the Snow Guards Compatibility Chart for Atas Corrugated Metal Roofing Panels.

The corrugated design of these panels makes them unsuitable for most traditional snow retention methods that require flat surfaces. However, we offer specialized solutions to address this challenge. One such solution is the SnoCleat 2.67, which can be installed directly on the high ribs of the panels using 3-inch screws, providing a secure attachment point. Wavy corrugated panels like these are exempt from the rules regarding screwing through the high ribs of panels because these brackets span multiple ribs. Customers seeking a continuous snow rail or snow fence system can use SnoBar or ColorBar with the same 2.67 brackets as the SnoCleat. The ColorBracket 2.67 comes with six attachment holes. While the minimum requirement is four, you can use all six screw holes, which will enhance the mounting strength, particularly in more extreme weather conditions.

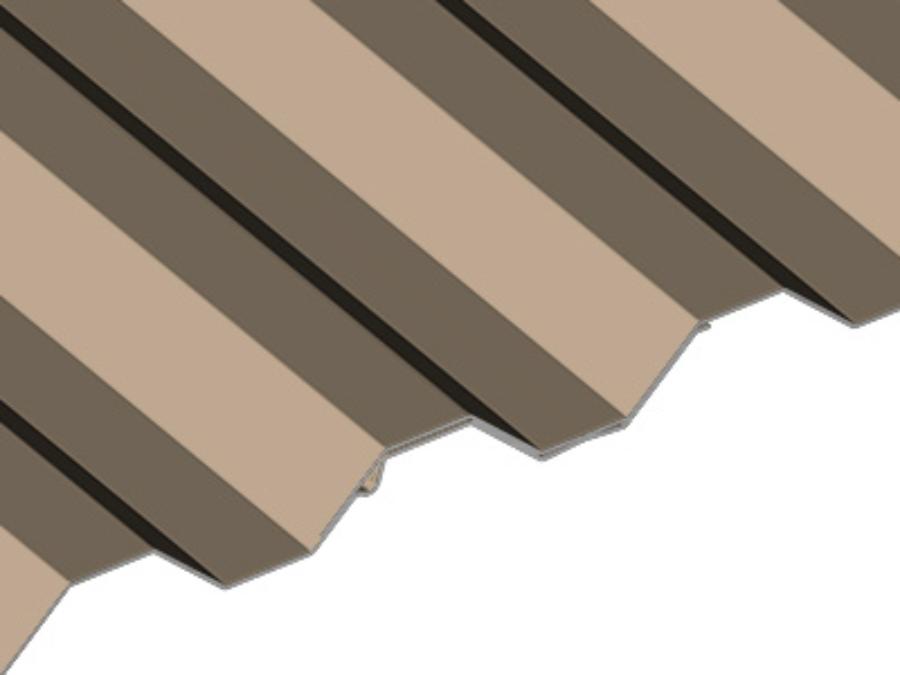

Grand C Metal Panels

The Grand C metal roof panel is a versatile product for various applications. Made of 0.032" thick aluminum, the Grand C features a .5625" high profile and measures 32.25" wide. The Grand C panel is suitable for use on walls, fascias, mansards, equipment screens, and even some limited roofing applications, provided the minimum slope is 3:12. Vented options are available for headwalls, ridges and shed ridges, further expanding the panel's versatility. The Grand C is part of ATAS's Belvedere metal roofing and wall panel product line. See the Snow Guards Compatibility Chart for Atas Grand C Metal Roofing Panels.

Although the ribs on this panel are trapezoidal rather than round and wavy like the Corrugated Metal Panels, the flats are too narrow for snow guards that require flat mounting areas for installation. Because the Grand C shares the same 2.67" spacing dimensions as ATAS's round, wavy corrugated panels, you can still utilize the SnoCleat 2.67, SnoBar, or ColorBar systems with the same 2.67 brackets for all three products. The installation instructions for this panel are consistent with those for a conventional wavy corrugated panel.

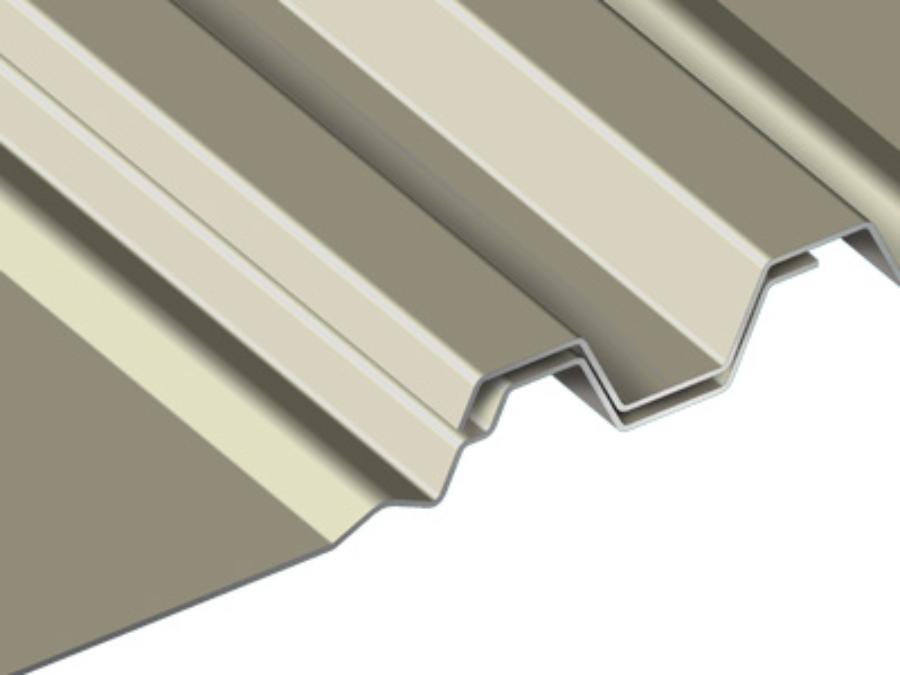

Grand V Metal Panels

The Grand V Metal Panel is a versatile cladding solution for walls and roofs made from 0.032-inch thick aluminum. One of the key features of the Grand V panel is its through-fastened design, which allows installation over solid substrates or open framing with support members spaced up to 24 inches apart. You can use this panel for various applications, including wall cladding, fascia installations, mansard roofs, equipment enclosures, and select roofing projects with a minimum pitch of 3:12. In addition to its functional capabilities, the Grand V panel also has a unique visual appeal. Its combination of form and function makes the Grand V panel an attractive choice for metal cladding projects prioritizing design and performance. See the Snow Guards Compatibility Chart for Atas Grand V Metal Roofing Panels.

Grand V Metal Panels are unusual compared to the other r-panel style exposed fastener panels discussed in this blog series. This panel features 8"-spaced double ribs and a centered minor rib striation. Because of this panel's narrow major rib spacing and the unique central rib striation, we recommend only using pad-style polycarbonate snow guards that can straddle ribs. The Snojax I, Snojax II, Icejax I, and Icejax II are perfect for use on this panel. These guards would typically be mounted off-center on a standard 9" R-Panel or 12" PBR panel. Still, we recommend centered installation for this panel.

Regarding the attachment of polycarbonate snow guards, most of these models, except for the Snojax I, can be attached to this panel using either adhesive or screws. The Snojax I is only compatible with mechanical fastener installation. It is essential to use Surebond SB-190 adhesive only for polycarbonate models, as this glue is incompatible with metal pad-style snow guards. These panels are compatible with our screw-down SnoBar and ColorBar, requiring the Tall ColorBrackets to be mounted off-center. Consistent mounting and spacing of these brackets is crucial in such instances. Avoid attaching individual snow guards or rail systems directly to the high ribs of the panel. Instead, opt for securing them by screwing down through the panel's low flats into a sturdy structure to ensure optimal installation strength.

Arc-Metafor Metal Panels

The Arc-Metafor is a unique curved metal roof and wall panel with a structural ribbed design with four prominent vertical ribs, allowing its installation in convex or concave configurations. Crafted from durable .032 aluminum, the Arc-Metafor comes in an extensive selection of over 30 standard colors and anodized finishes, enabling designers to achieve a wide range of aesthetic effects. This panel can be oriented horizontally or vertically. With a maximum length of 5'9" for the convex profile and 10'0" for the concave, the Arc-Metafor offers considerable design flexibility to suit various architectural applications. Whether specified with a smooth or stucco-embossed surface, this curved metal panel provides an eye-catching, structurally sound solution for new construction and renovation projects. See the Snow Guards Compatibility Chart for Atas Arc-Metafor Metal Roofing Panels.

Even though this panel could technically be grouped in with hidden fastener roofing, because it is installed like a nail strip and doesn't have an exposed seam, I have chosen to mix it in with these panels. Due to its dimensions and styling, we currently do not offer a snow guard option for this panel when used on radiused roofing. If used in non-radiused roofing, we estimate that the Tall ColorBracket will fit tightly in the flats and thus enable the use of SnoBar or ColorBar rail systems. We advise a test fit of the ColorBracket before placing your main order. Samples are available for purchase on our website.

Snow Guards Compatibility Chart for ATAS Metal Roofing

| Belvedere Grand R Profile | Corrugated Profile | Grand C Profile | Grand V Profile | Arc-Metafor Profile | |

|---|---|---|---|---|---|

| IceJax I Screw Down | YES | NO | NO | YES | NO |

| IceJax I Glue Down | YES | NO | NO | YES | NO |

| IceJax II Screw Down | YES | NO | NO | YES | NO |

| IceJax II Glue Down | YES | NO | NO | YES | NO |

| SnoBlox Deuce Screw Down | YES | NO | NO | YES | NO |

| SnoBlox Deuce Glue Down | YES | NO | NO | YES | NO |

| SnoBlox Ace Screw Down | YES | NO | NO | NO | NO |

| SnoBlox Ace Glue Down | YES | NO | NO | NO | NO |

| Snojax I Screw Down | YES | NO | NO | YES | NO |

| Snojax II Screw Down | YES | NO | NO | YES | NO |

| Snojax II Glue Down | YES | NO | NO | YES | NO |

| SnowBreaker 3M | YES | NO | NO | YES | NO |

| SnowBreaker Screw Down | YES | NO | NO | YES | NO |

| SnowBreaker Glue Down | YES | NO | NO | YES | NO |

| SnowCatcher | YES | NO | NO | NO | NO |

| Decorative SnowCatcher | YES | NO | NO | NO | NO |

| SnoCleat PBR | YES | NO | NO | NO | NO |

| SnoCleat 2.67 | NO | YES | YES | NO | NO |

| SnoBar PBR | YES | NO | NO | YES | YES |

| ColorBar PBR | YES | NO | NO | YES | YES |

| SnoBar 2.67 | NO | YES | YES | NO | NO |

| ColorBar 2.67 | NO | YES | YES | NO | NO |

Snow Guards: Purchasing and Installation Considerations for ATAS Exposed Fastener Metal Roofing

1. Timing for Glue-Down Snow Guard Installation

The optimal time to install glue-down snow guards is late spring or early summer. The industry-standard adhesive, Surebond SB-190, requires approximately 28 days at 50 degrees Fahrenheit to cure fully. Temperatures below 50 degrees Fahrenheit will temporarily halt the curing process until the temperature rises. Careful planning is essential when scheduling the installation of glue-down snow guards, as the adhesive needs sufficient time to cure properly. In contrast, screw-down snow guards and rail systems offer year-round installation if the roof is free of snow, ice, and debris.

2. Importance of a Layout Plan

Obtaining a design recommendation from the snow guard manufacturer is essential, regardless of the type of snow retention system you're installing. We offer free spacing charts and quote request forms to assist customers seeking custom layout guidance. Limiting snow retention systems to isolated areas is not advisable. This installation method consistently poses a high risk of failure and should be avoided. Instead, it's essential to consider a more comprehensive approach to snow retention that addresses the entire roofing system.

3. Structural Support for Snow Guards

When installing snow guards with mechanical fasteners, anchoring them into at least 1 inch of solid wood structure, such as plywood decking, purlins, or retrofitting blocking, is crucial. For pre-engineered metal buildings, it is best to mount snow guards into metal purlins whenever possible. Solely relying on the panel as the structural support for snow guards or rails is not advisable, as it carries a significant risk of failure. You should consider an alternative solution if the underlying structure at the proposed snow guard mounting locations is insufficient and the ground snow load is 45 pounds per square foot or less. In such cases, if the installer cannot add additional blocking, a glue-down snow guard product is a more suitable option.

4. Preventing Roof Leaks

Products like the SnoCleat PBR, SnoCleat 2.67, SnowCatchers, and screw-down rail systems come equipped with butyl tape gaskets designed to seal without liquid sealant. When paired with screws featuring neoprene washers, this ensures a secure barrier against the elements. While not mandatory, some customers apply liquid silicone around the edges of these snow guards to add an extra layer of protection. When attaching any polycarbonate snow guards to the roof using screws, it is crucial to utilize a neutral curing, cold-weather liquid silicone, like our suggested NovaFlex MR150, to seal the entire base effectively.

5. Understanding Ground Snow Load

The ground snow load is critical in selecting the appropriate snow retention system. This data, derived from historical records, is gathered by weather stations nationwide. For projects encountering ground snow loads up to 45 pounds per square foot (PSF), you may consider glue-down or screw-down individual snow guards or screw-down snow rail systems. We advise installing snow rail systems exclusively in regions where ground snow loads exceed this threshold. You can typically obtain information about the ground snow loads for your project through an online search or by reviewing the building plans.

6. Color-Matching Options

We provide various color-matching solutions to guarantee your snow guards blend seamlessly with your roof, including slide-in color strips for our SnoCleat and ColorBar products and powder-coating options for all metal snow guards and rail systems to achieve a perfect color match. Our powder-coated products are custom-made upon order and typically have a lead time of 3 to 4 weeks, depending on the color and project size. Customers also have the flexibility to have their snow guards powder-coated locally or painted upon arrival, resulting in a quicker turnaround and greater control over color selection.

Conclusion

Selecting the appropriate snow guards for your project may seem daunting initially. This blog series offers insightful guidance to alleviate any uncertainties you may encounter. As our series progresses, you can anticipate broader coverage encompassing more roof panel manufacturers in forthcoming articles. When buying snow guards, it's vital to enlist support from a reputable and easily accessible company. They should be able to address your questions and offer assistance. SnoBlox-Snojax is an exemplary manufacturer that consistently meets and often surpasses this criterion. Don't hesitate to contact us at support@snojax.com or dial 1-800-766-5291 for any inquiries or orders. Moreover, delve into our Snow Guard Buyer's Guide and What Works and What Doesn't Page on our website for valuable insights to facilitate decision-making.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.