Snow Guards For Star Building Systems Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Nov 6th 2024

See the Snow Guards Compatibility Chart for Star Building Systems Screw Down Metal Roofing Panels.

Do I Need Snow Guards for Star Building Systems Screw Down Metal Roofing?

Winter presents unique challenges for buildings with exposed fastener metal roofs, primarily due to the risk of sudden snow and ice slides.

The smooth nature of these roofs increases the likelihood of snow avalanches, posing significant threats to people, pets, and the surrounding property. We have engineered adaptable snow retention solutions for metal roofing to mitigate this issue. Customers and installers can customize our innovative snow guards and rail systems to match various metal roof designs. We design our products to effectively manage snow accumulation, providing a tailored solution for different metal roofing styles and structures. When implementing these protective measures, it's crucial to consider several factors, including the roof's pitch, panel configuration, and the specific climate conditions of the area. To assist property owners in making informed decisions, we offer a range of educational resources, including our blog posts, informative web pages, and a comprehensive database of compatible metal panel manufacturers for snow retention solutions. By focusing on education and innovative approaches, we aim to reduce the risks associated with snow and ice buildup, ultimately creating safer environments in regions that experience heavy snowfall. These efforts are vital in addressing the hazards posed by exposed fastener metal roofs during winter months, ensuring the protection of both individuals and property. By adopting effective snow retention systems and increasing awareness of their importance, building owners can significantly minimize the dangers of winter weather conditions.

Exposed Fastener Metal Roof Panels by Star Building Systems

Star Building Systems, founded in 1927, initially catered to Oklahoma's oil industry by producing small tool sheds for derrick sites. Over time, the company evolved significantly, expanding its offerings to include various custom-engineered commercial and industrial construction solutions. This evolution allowed Star to adapt to changing market demands and technological advancements. Star has demonstrated remarkable versatility throughout its history, supplying structures for diverse applications, including aircraft hangars during World War II. Today, the company offers an extensive array of cutting-edge building systems, solidifying its position as an industry leader. As part of Cornerstone Building Brands, Star benefits from the resources and expertise of one of North America's largest manufacturers of exterior building products. Star's enduring success stems from its consistent commitment to innovation, quality, and customer satisfaction. The company specializes in customizable metal building systems for long-term durability and performance. By adopting a customer-centric approach, Star provides its network of builders with comprehensive tools, training, and support, enabling them to thrive in their local markets while maintaining a strong nationwide presence.

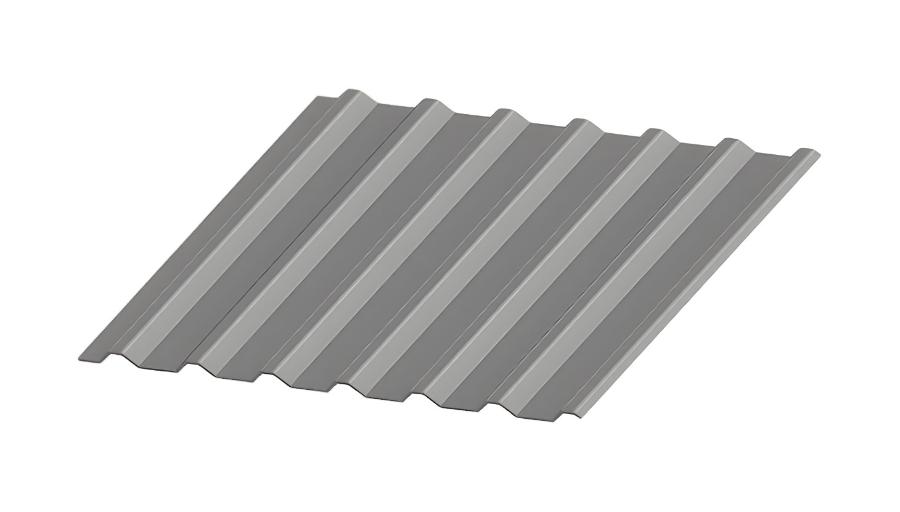

PBR

The PBR panel is a versatile and economical choice for metal building construction. It is suitable for roofing and wall applications. This panel features a 36-inch coverage width with deep ribs measuring 1-1/4 inches in height, spaced 12 inches apart on-center. Minor ribs between the major ones enhance the panel's structural strength and create an appealing shadowed look. Star typically produces PBR panels in 26 gauge while also offering 22 and 24-gauge options. Installers can mount these panels on roof slopes as low as 1/2:12.The exposed fastening system of the PBR panel allows for easy installation on open framing or solid substrates. Its versatility extends beyond roofing, including wall cladding, liner panels, mansards, and soffits. Star Building Systems offers various finish options, including Galvalume Plus® coating and Signature® 200 and 300 paint finishes, with a choice between a standard smooth surface or an optional embossed texture. Many agricultural, commercial, industrial, and architectural projects widely use the PBR panel because it is durable, weather-resistant, and cost-effective. Its ability to serve multiple functions in building design, attractive appearance, and robust construction has made it a popular choice in the metal building industry. The PBR panel's proven performance and adaptability make it a preferred option for many construction projects. See the Snow Guards Compatibility Chart for Star Building Systems PBR Screw Down Metal Roofing Panels.

This panel showcases exceptional adaptability for snow guard installation, offering a wide range of options to meet various project requirements and preferences. It can accommodate different snow guard types, including screw-fastened rail systems and an assortment of stainless steel SnowCatchers with unique designs. Most polycarbonate snow guard models can be attached using adhesive or screw-down methods, except for the Snojax I, which requires screw-down installation only. Position smaller snow guards between the minor ribs in the center of the panel for optimal performance. However, specific models like the Snojax II and Icejax II need off-center placement, consistently straddling either the left or right minor rib or mesa. It is important to note that snow guards or rail systems should not be attached directly to the panel's high ribs. To achieve maximum stability and strength, mount them through the low, flat sections of the panel into a robust underlying structure. When using adhesive to install polycarbonate models, it is crucial to use the industry-standard Surebond SB-190 adhesive. However, this particular adhesive is not suitable for metal pad-style snow guards. By following these guidelines, installers can ensure the most effective and durable installation of snow guards on these versatile panels, providing reliable protection against snow and ice accumulation.

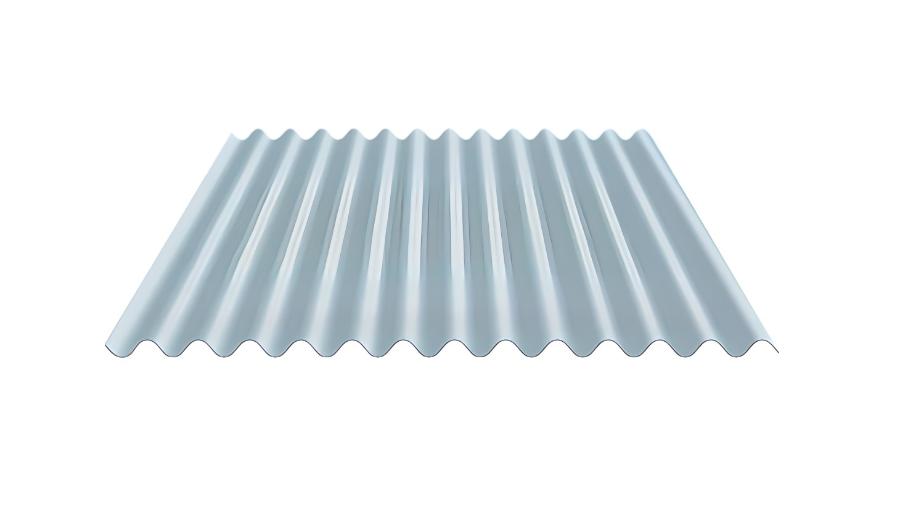

PBC

The PBC panel is versatile for roofing and wall applications. This exposed fastener system is particularly effective when used horizontally on walls, offering flexibility in design and installation. The panel ensures adequate water drainage with a coverage width of 32 inches and a minimum roof slope requirement of 3:12 pitch. Available in standard 26 gauge and optional 24 and 22 gauge options, the PBC panel features ribs spaced 2.67 inches apart with a height of ⁷⁄₈ inch. This configuration contributes to its structural integrity and visual appeal. Depending on their project requirements, customers can choose between smooth or embossed surface finishes. The panel's coating options include Galvalume Plus® and two Signature® variants, enhancing its durability and weather resistance. The PBC panel's design prioritizes ease of installation while maintaining robustness. Its adaptability makes it a popular choice for various building projects, seamlessly integrating into Star Building Systems' comprehensive range of metal panel offerings. This combination of practicality and versatility positions the PBC panel as a valuable option for builders and architects seeking reliable and attractive building envelope solutions. See the Snow Guards Compatibility Chart for Star Building Systems PBC Screw Down Metal Roofing Panels.

The distinctive wavy pattern of the PBC Panel sets it apart from traditional exposed fastener roofing, offering a unique approach to snow guard installation. Unlike conventional methods, this panel allows mounting on its high ribs, providing versatility for customers seeking snow retention solutions. The panel is compatible with various options, including the recently introduced SnoCleat 2.67 snow guards, which can be firmly attached to the high ribs using 3-inch screws. The SnoBar and ColorBar options are available for those preferring alternative systems, utilizing the versatile ColorBracket 2.67. This bracket, also employed with the SnoCleat 2.67, features six attachment points, offering flexibility during installation. You can generally use four screws per bracket for adequate support, but utilizing all six screws enhances strength, especially in areas prone to harsh weather conditions. This innovative design gives customers various choices to suit their snow retention needs while maintaining the panel's distinctive aesthetic appeal.

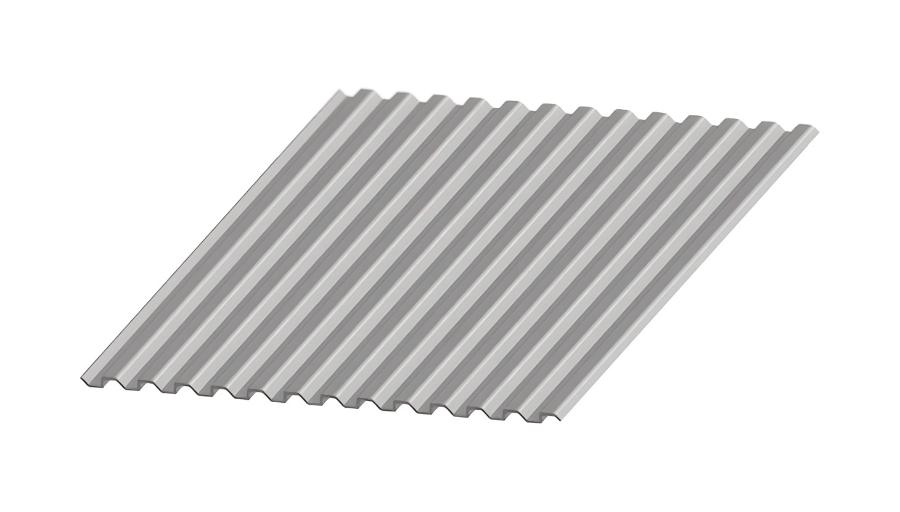

PBD

Star Building Systems offers the PBD panel, a versatile exposed-fastened system suitable for roof and wall applications. This panel features ribs spaced 2.67 inches apart with a height of 5/8 inches, providing a contemporary aesthetic. This panel features a more trapezoidal appearance, unlike a standard wavy corrugated panel. The PBD panel's flexibility allows for direct installation over purlins or joists, and it can be mounted vertically or horizontally when used as wall cladding. This adaptability gives designers more options to achieve their desired architectural look. As part of Star Building Systems' comprehensive range of metal panel solutions, the PBD panel meets high durability and weather resistance standards. This panel has 22, 24, 26, and 29 gauge options and various colors and coatings. Like other panels in their lineup, the PBD undergoes rigorous testing for water penetration, uplift resistance, and structural integrity to ensure compliance with building codes. The PBD panel and Star's other metal roofing and wall systems present an alternative to traditional construction methods. These panels offer greater project flexibility, reduce construction timelines, and provide long-lasting performance against environmental factors. By choosing the PBD panel, builders and designers can access a modern building solution that combines functionality with aesthetic appeal, contributing to their projects' overall efficiency and appearance. See the Snow Guards Compatibility Chart for Star Building Systems PBD Screw Down Metal Roofing Panels.

The PBD Panel stands out among typical exposed fastener roofing options due to its distinctive design. This unique structure allows for an unconventional approach to snow guard mounting, permitting installation on the panel's elevated ribs. This panel offers several compatible options for customers needing snow retention systems. The recently introduced SnoCleat 2.67 snow guards can be securely fastened to the high ribs using 3-inch screws. Alternatively, the SnoBar and ColorBar systems are available, utilizing the ColorBracket 2.67, the same bracket employed by the SnoCleat 2.67. This versatile bracket features six attachment points, providing installation flexibility. While four screws per bracket are typically sufficient, using all six holes can offer increased mounting strength, which may be advantageous in regions experiencing more severe weather conditions.

PBU

Star Building Systems offers the PBU panel, a versatile metal panel system for roofing and wall applications. This exposed fastener panel features a 36-inch coverage width and is suitable for roofs with a minimum slope of 1:12. The PBU panel's design includes 3/4-inch high ribs spaced 6 inches apart on center. While the standard gauge is 26, customers can choose 24 or 22-gauge options. The panel comes in smooth or embossed finishes and can be coated with Galvalume Plus® or Signature® 200 or 300 finishes. Its design allows for direct installation over purlins or joists, and it can be oriented vertically and horizontally, offering flexibility for modern, contemporary building aesthetics. The PBU panel has earned a UL 90 rating under construction number 39, demonstrating its performance capabilities. Its versatility makes it suitable for various architectural, commercial, and industrial projects. As part of Star Building Systems' metal panel lineup, the PBU panel withstands diverse weather conditions. It has undergone independent testing for water resistance, uplift ratings, and structural integrity. These tests ensure the panel meets or exceeds relevant building code requirements, providing a reliable and durable option for construction needs. See the Snow Guards Compatibility Chart for Star Building Systems PBU Screw Down Metal Roofing Panels.

The unique design of PBU panels, characterized by narrow and flat areas measuring about 3 1/2 inches wide, poses specific challenges for implementing snow retention systems. However, effective solutions are within reach. Several options exist for those seeking to manage snow and ice accumulation on their roofs. The recommended models for secure snow and ice retention are the Ace, Deuce, and Icejax I. Individual polycarbonate snow guard pads have also proven effective in retaining snow on rooftops. For those who prefer a controlled snow-shedding approach, the SnowBreaker and SnowBreaker 3M models offer solutions that release snow and ice in smaller, less dangerous quantities. A key advantage of all these models is their installation flexibility, as they can be mounted using screws, 3M double-sided tape, or Surebond SB-190 adhesive. Additionally, for those who favor a bar-style snow retention system, the PBU panel is compatible with tall ColorBrackets, which allow for the mechanical attachment of SnoBar and ColorBar systems.

Star Building Systems Compatibility Chart for Snow Guards

| PBR Panel | PBC Panel | PBD Panel | PBU Profile | |

|---|---|---|---|---|

| IceJax I Screw Down | YES | NO | NO | YES |

| IceJax I Glue Down | YES | NO | NO | YES |

| IceJax II Screw Down | YES | NO | NO | NO |

| IceJax II Glue Down | YES | NO | NO | NO |

| SnoBlox Deuce Screw Down | YES | NO | NO | YES |

| SnoBlox Deuce Glue Down | YES | NO | NO | YES |

| SnoBlox Ace Screw Down | YES | NO | NO | YES |

| SnoBlox Ace Glue Down | YES | NO | NO | YES |

| Snojax I Screw Down | YES | NO | NO | NO |

| Snojax II Screw Down | YES | NO | NO | NO |

| Snojax II Glue Down | YES | NO | NO | NO |

| SnowBreaker 3M | YES | NO | NO | YES |

| SnowBreaker Screw Down | YES | NO | NO | YES |

| SnowBreaker Glue Down | YES | NO | NO | YES |

| SnowCatcher | YES | NO | NO | NO |

| Decorative SnowCatcher | YES | NO | NO | NO |

| SnoCleat PBR | YES | NO | NO | YES |

| SnoCleat 2.67 | NO | YES | YES | NO |

| SnoBar PBR | YES | NO | NO | YES |

| ColorBar PBR | YES | NO | NO | YES |

| SnoBar 2.67 | NO | YES | YES | NO |

| ColorBar 2.67 | NO | YES | YES | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Star Building Systems

Enhancing Roof Aesthetics with Snow Retention Systems

When incorporating snow guards into your roof design, it's crucial to maintain visual harmony. Look for customizable options such as color-matched inserts or powder-coated finishes to ensure your snow retention system blends seamlessly with your roof's appearance. While local coating services or DIY methods can provide quick solutions, professional powder coating may take longer but often yields superior, long-lasting results.

Strategically Positioning Snow Guards

Their placement largely determines the efficacy of snow guards. Please adhere to our recommended guidelines for optimal arrangement. Avoid concentrating guards in isolated areas, such as above doorways or paths, as this can overburden the system and potentially cause it to fail. Proper weight distribution is critical to ensuring the system's overall effectiveness.

Assessing Your Roof's Snow-Bearing Capacity

Before choosing a snow retention system, evaluate your roof's ability to handle snow loads. Reference local weather data or "ground snow load" information to inform your decision. Individual guards or screw-down rails are often sufficient in regions with ground snow loads up to 45 PSF. However, areas experiencing heavier snowfall may require more robust rail systems exclusively.

Ensuring Watertight Installations

Proper silicone sealant application is crucial for screw-mounted polycarbonate snow guards. Apply adequate pressure to ensure complete base coverage and eliminate air pockets. While metal guards and rail brackets typically come with waterproof gaskets, some installers apply additional sealant around the edges for extra protection, though this is only sometimes necessary.

Optimal Timing for Snow Guard Installation

Installing adhesive-mounted snow guards is a time-sensitive process. In North America, the ideal period is typically during warmer months, such as late spring or early summer. This timing allows for proper adhesive curing, which requires about 30 days of temperatures above 50°F. While rain isn't a concern after 24 hours, cold temperatures can impede curing. Surebond SB190 adhesive is the industry standard for installing polycarbonate plastic snow guards.

Proper Mounting Techniques for Snow Guards

Correct attachment is vital for mechanically mounted snow guards. Make sure to attach them to a solid foundation, ideally using at least 1 inch of sturdy wood such as plywood decking or purlins. For metal structures, attach to metal purlins. Avoid relying solely on the roof panel for support. Consider using adhesive-mounted guards if reinforcement isn't feasible on less robust roofs.

Special Considerations for Curved or Radiused Roof Panels

Roofs featuring curved or radiused panels are not suitable for pad-style guards. These snow retention systems require a flat surface for proper attachment using adhesive or screws and sealant. Installers should explore alternative solutions for such roof designs to ensure effective snow retention.

Conclusion

SnoBlox-Snojax takes pride in offering outstanding customer support for snow guard installations, focusing on enduring solutions rather than quick fixes. Our primary objective is to ensure our clients comprehensively understand our product range. We employ a meticulous approach that blends personalized assistance with various resources, providing our customers with the essential knowledge and tools required for successful implementation. By offering direct communication with our support team and supplying practical guides and tools, we empower our clients to thoroughly maximize the benefits of our products. Our steadfast commitment to quality and real-world effectiveness underscores our dedication to delivering superior solutions, showcasing our devotion to product excellence and customer satisfaction. To assist clients in making well-informed decisions, we have created valuable resources such as a Snow Guard Buyer's Guide and a "What Works and What Doesn't" page. These materials offer crucial insights and practical information to aid decision-making. We actively encourage customers who require assistance with their orders to contact our support team via phone or email, ensuring they receive the necessary guidance to achieve optimal results with our snow guard products.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.