Snow Guards For Everlast Metals Exposed Fastener Metal Roof Panels

Posted by Derek Gamble - SnoBlox-Snojax Specialist on Nov 20th 2024

See the Snow Guards Compatibility Chart for Everlast Metals Screw Down Metal Roofing Panels.

Do I Need Snow Guards for Everlast Metals Screw Down Steel Roofing?

During winter, buildings with exposed fastener metal roofs face unique challenges, particularly the risk of sudden snow and ice slides.

The smooth surface of these roofs increases the likelihood of snow avalanches, which can be dangerous for people, pets, and nearby property. We have developed specialized snow retention solutions for metal roofing to address this issue. These innovative systems, including adjustable snow guards and rail setups, can be tailored to suit various metal roof designs, effectively managing snow accumulation and providing customized solutions for metal roofing and building structures. When implementing these protective measures, it's essential to consider several factors, such as the roof's pitch, panel configuration, and local weather conditions. A range of educational resources is available to help property owners make informed decisions, including our blog posts, informative web pages, and a comprehensive list of compatible metal panel manufacturers for snow retention solutions. This focus on education and innovative approaches aims to mitigate the risks associated with snow and ice buildup, creating safer environments in areas prone to heavy snowfall. These efforts are crucial in addressing the hazards posed by exposed fastener metal roofs during winter, ensuring the safety of both individuals and property. Building owners can significantly reduce the dangers associated with winter weather on their metal roofs by implementing effective snow retention systems and raising awareness about their importance.

Exposed Fastener Metal Roof Panels by Everlast Metals

Everlast Metals, based in Lebanon, Pennsylvania, has established itself as a leading manufacturer of architectural metal roofing and wall systems. The company offers a comprehensive range of high-quality metal roofing and siding materials for architectural, commercial, and industrial applications. Their product lineup includes metal roof and wall systems, slit coils, and flat sheet distribution. With additional facilities in Orwell, OH, Bridgton, ME, and Howe, IN, Everlast Metals efficiently serves customers across multiple states. The company's diverse portfolio features metal panels in various colors and styles, including architectural and commercial panels. Everlast Metals also offers proprietary paint systems, such as the COLORBOND Paint System. Demonstrating a commitment to professional development within the industry, the company serves as an AIA/CES Continuing Education Provider, offering valuable educational opportunities for architects and other professionals to stay abreast of industry trends. Everlast Metals has garnered a reputation for excellence, with customers frequently praising their outstanding customer service, product quality, knowledgeable staff, and efficient delivery processes. Through their unwavering dedication to quality and customer satisfaction, Everlast Metals has solidified its position as a respected manufacturer of metal roofing and siding products, catering to a broad customer base.

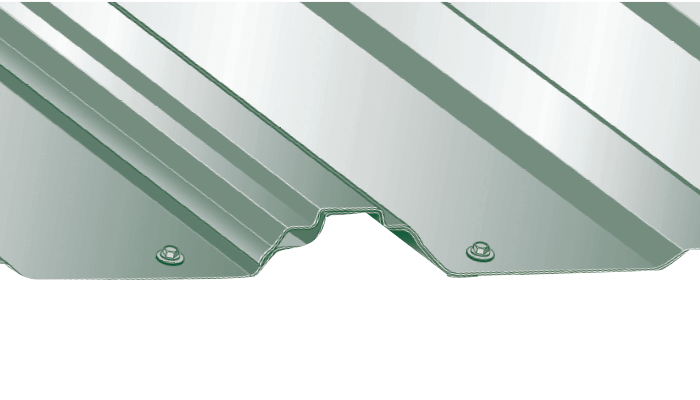

OMNI SERIES

The OMNI Series roof panel by Everlast Metals is a popular choice for residential metal roofing, and it is known for its attractive board and batten appearance. See the Snow Guards Compatibility Chart for Everlast Metals OMNI SERIES Screw Down Metal Roofing Panels.This panel system features a clean, crisp design combining aesthetic appeal and practical functionality. The panels interlock to create a weather-tight seal and incorporate a deep anti-siphon groove for enhanced leak protection. Each OMNI panel measures 36 inches in width, providing full coverage across its span. The panels can range from a minimum length of 36 inches to a maximum of 40 feet, offering flexibility for various roof sizes. A distinctive feature of the OMNI Series is its rib pattern, with major ribs spaced 9 inches apart and two minor ribs, standing 3/16 inches high, positioned between them. This configuration contributes to the panel's structural integrity and visual appeal. The OMNI Series has two gauge options: a 27 gauge Omni and a 29 gauge Economy version. Both utilize high-quality materials, with the Omni gauge featuring AZM® 125 WITH ACTIVATE TECHNOLOGY as its substrate. In contrast, the Economy gauge offers a choice of Galfan, Galvalume, or Galvanized substrates. Both versions are finished with Synergy™ coating, enhancing their durability and appearance. Installation of OMNI Series panels is straightforward, requiring only conventional hand or power tools and no field seaming. The durability of the OMNI Series is noteworthy, particularly for the Omni gauge. It boasts a 50-year film integrity warranty, 35-year fade or chalk resistance, and 15-year red rust resistance. Additionally, it comes with a 25-year performance warranty. While more budget-friendly, the Economy gauge offers a 10-year film integrity warranty.

This panel offers versatility with snow retention solutions, accommodating a wide range of installation methods and material preferences. For polycarbonate options, industry professionals suggest placing products like SnoBlox Deuce and SnowBreaker variants in the spaces between minor ribs. Metal enthusiasts can opt for screw-mounted solutions such as the SnoCleat PBR and our diverse SnowCatcher designs, best suited for installation in the panel's central flat area. The Snojax I and Icejax I provide additional choices for spanning minor ribs between 9" sections, with the Icejax I offering both adhesive and screw mounting options, while the Snojax I requires mechanical fasteners exclusively. Customers can combine this panel with Tall ColorBrackets and appropriate fasteners to support aluminum ColorBar PBR or galvanized SnoBar PBR snow rail systems for a comprehensive snow management approach. This integrated solution delivers a robust and efficient method for managing snow accumulation, ensuring optimal performance across various weather conditions and environmental factors.

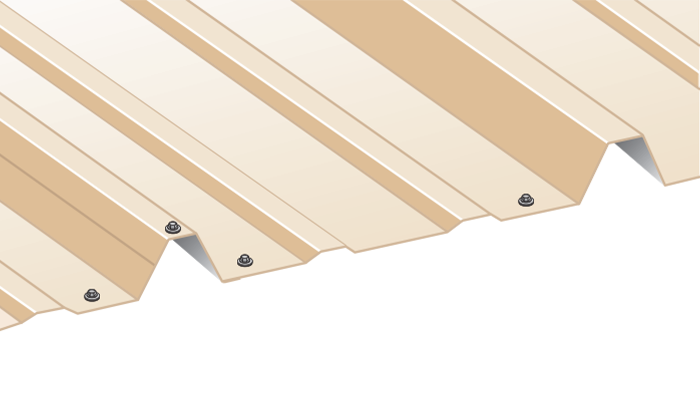

PBR PANEL

The PBR Panel from Everlast Metals is a versatile and robust metal panel designed for roofing and siding applications.See the Snow Guards Compatibility Chart for Everlast Metals PBR Screw Down Metal Roofing Panels. This adaptable product is well-suited for various exterior uses, including industrial, commercial, and agricultural buildings. It can even serve as an interior liner panel. The panel features a width of 36 inches and a seam height of 1 1/4 inches, with its major ribs on 12" spacing. Lengths range from a minimum of 36 inches to 40 feet. Customers can choose from unpainted Galvalume® Plus substrate in 24 and 26-gauge or painted 26-gauge Galvalume® substrate in various colors. The PBR Panel offers impressive performance features, including a watertight side lap and a minimum slope requirement of 1:12 pitch, providing optimum strength for maximum spanning capabilities. A 35-year finish warranty backs its durability for painted panels, and it boasts UL 2218 Class 4 Impact Resistance and UL 790 Class A Fire Resistance ratings. Installation of the PBR Panel is straightforward, using conventional hand or power tools. With its durability, versatility, and aesthetic appeal, the PBR Panel by Everlast Metals presents an excellent choice for various construction projects that demand functionality and visual appeal.

This panel demonstrates remarkable versatility in snow guard installation, providing diverse choices to suit project needs and preferences. It is compatible with various snow guard types, including screw-fastened rail systems and distinctively designed stainless steel SnowCatchers. Most polycarbonate snow guard models can be affixed using adhesive or screw-down methods, except for the Snojax I, which exclusively requires screw-down installation. Installers should position smaller snow guards between the minor ribs in the panel's center to ensure optimal performance. However, certain models like the Snojax II and Icejax II require off-center placement, consistently straddling the left or right minor ribs or mesas. It's crucial to avoid attaching snow guards or rail systems directly to the panel's high ribs. To achieve maximum stability and strength, mount them through the low, flat sections of the panel into a sturdy underlying structure. When using adhesive for polycarbonate model installation, it's essential to use the industry-standard Surebond SB-190 adhesive. However, this particular adhesive is not appropriate for metal pad-style snow guards. By adhering to these guidelines, installers can ensure the most effective and long-lasting installation of snow guards on these adaptable panels, providing dependable protection against snow and ice buildup.

Everlast Metals Compatibility Chart for Snow Guards

| OMNI Series | PBR Panel | |

|---|---|---|

| IceJax I Screw Down | YES | YES |

| IceJax I Glue Down | YES | YES |

| IceJax II Screw Down | NO | YES |

| IceJax II Glue Down | NO | YES |

| SnoBlox Deuce Screw Down | YES | YES |

| SnoBlox Deuce Glue Down | YES | YES |

| SnoBlox Ace Screw Down | NO | YES |

| SnoBlox Ace Glue Down | NO | YES |

| Snojax I Screw Down | YES | YES |

| Snojax II Screw Down | NO | YES |

| Snojax II Glue Down | NO | YES |

| SnowBreaker 3M | YES | YES |

| SnowBreaker Screw Down | YES | YES |

| SnowBreaker Glue Down | YES | YES |

| SnowCatcher | YES | YES |

| Decorative SnowCatcher | YES | YES |

| SnoCleat PBR | YES | YES |

| SnoCleat 2.67 | NO | NO |

| SnoBar PBR | YES | YES |

| ColorBar PBR | YES | YES |

| SnoBar 2.67 | NO | NO |

| ColorBar 2.67 | NO | NO |

Considerations for Adding Snow Guards to Exposed Fastener Roofs by Everlast Metals

Ideal Timing for Installing Snow Guards

The timing of installing adhesive-mounted snow guards is critical. In North America, late spring or early summer is typically the best period for installation. This timing allows the adhesive to cure properly, which usually takes about 30 days at temperatures above 50°F. Although rain won't affect the adhesive after 24 hours, cold temperatures can impede curing. Surebond SB-190 adhesive is the industry standard for installing polycarbonate plastic snow guards.

Assessing Your Roof's Snow Load Capacity

Before choosing a snow retention system, evaluate your roof's ability to handle snow loads. Refer to local weather data or "ground snow load" figures to inform your decision. Individual guards or screw-down rails may be adequate in regions with ground snow loads up to 45 PSF. Areas with heavier snowfall require more robust rail systems.

Enhancing Your Roof's Aesthetic with Snow Retention Solutions

Integrating snow guards into your roofing design demands a focus on visual appeal. Choose customizable options such as color-matched inserts or powder-coated finishes to ensure your snow retention system blends with your roof's overall design. While local coating services or DIY methods may provide quick fixes, professional powder coating, although it takes more time, generally results in a higher quality and more durable finish.

Proper Techniques for Mounting Snow Guards

Properly securing snow guards is essential for mechanically mounted systems. Ensure they are attached to a solid base, ideally using at least one inch of sturdy wood like plywood decking or purlins. For metal roofs, fasten to metal purlins rather than relying solely on the roof panel for support. If reinforcement on weaker roofs isn't feasible, consider using adhesive-mounted guards.

Effective Placement of Snow Guards

The placement of snow guards plays a crucial role in their effectiveness. Adhere to recommended guidelines for optimal positioning. Avoid concentrating guards in isolated areas, like directly over doorways or walkways, as this can overload the system and lead to potential failures. Achieving an even weight distribution is essential for the system's overall performance.

Ensuring Secure Installations

Correctly applying silicone sealant is vital for screw-mounted polycarbonate snow guards. Make sure to exert enough pressure for complete base coverage and to eliminate air pockets. While metal guards and rail brackets often come equipped with waterproof gaskets, some installers add sealant around the edges for extra protection. However, this may only sometimes be necessary.

Special Considerations for Curved Roof Panels

Curved or radiused roof panels are not suitable for pad-style guards, which require a flat surface for effective attachment with adhesive or screws and sealant. Installers should explore alternative solutions specifically designed for these types of roofs to ensure effective snow retention.

Conclusion

SnoBlox-Snojax takes pride in offering outstanding customer support for snow guard installations, focusing on enduring solutions rather than quick fixes. Our primary objective is to ensure our clients understand our product range comprehensively. We employ a meticulous approach that blends individualized assistance with various resources, equipping our customers with the essential knowledge and tools for successful implementation. By providing direct access to our support team and offering practical guides and tools, we fully empower our clients to leverage our products' advantages. Our steadfast commitment to quality and real-world effectiveness underscores our dedication to delivering superior solutions, showcasing our devotion to product excellence and customer satisfaction. To assist clients in making well-informed decisions, we have created valuable resources such as a Snow Guard Buyer's Guide and a "What Works and What Doesn't" page. These materials offer crucial insights and practical information to aid decision-making. We actively encourage customers who require assistance with their orders to contact our support team via phone or email, ensuring they receive the necessary guidance to achieve optimal results with our snow guard products.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.