Snow Guards For Exposed Fastener Metal Roof Panels by Berridge

Posted by Derek Gamble - SnoBlox-Snojax Specialist on May 20th 2024

See the Snow Guards Compatibility Chart for Berridge Manufacturing Screw Down Metal Roofing Panels.

Being proactive is critical when installing snow guards and snow retention systems on exposed fastener metal roofs, as failing to do so can leave your property vulnerable to the dangers of sliding snow and ice. The unique designs of various metal roof panels often require specialized snow guard solutions to manage and mitigate these winter weather challenges effectively. This practical guide presents a range of snow guard options compatible with Berridge's exposed fastener metal panels, giving you the knowledge to make an informed decision that fits your roof system's needs. As part of an ongoing series, these blogs will highlight prominent metal panel manufacturers and recommend compatible snow guard solutions. The goal is to empower you with the confidence and expertise to navigate this process smoothly, enabling you to make well-informed choices that safeguard your investment and prioritize your property's and its occupants' safety. We provide detailed information to help you select the most appropriate snow guard system. This guidance ensures optimal protection and peace of mind throughout the harsh winter months.

Exposed Fastener Metal Roof Panels by Berridge

Berridge Manufacturing Company was founded in 1970 by Jack Berridge, a pioneer in the architectural metal panel industry. In its early years, the company manufactured metal panels and shingles for the architect-specified market. A significant innovation came in 1986 when Berridge introduced the first portable roll-former capable of fabricating curved and straight standing seam panels on job sites, giving contractors unprecedented control. Jack Berridge was a prolific innovator who patented products like the Vinyl Weatherseal and designed revolutionary systems like the Berridge Tee-Panel standing seam roofing system in 1971. The 1990s saw rapid expansion for Berridge, which resulted in building new facilities and opening branch plants nationwide. By 1999, they had over 150 employees and 300,000 square feet of plant and office space. That year, founder Jack Berridge retired after establishing the company as an industry leader through innovative designs and commitment to quality. Today, Berridge fabricates its portable roll-forming machines, which it leases or sells to nearly 300 licensed contractors nationwide. The company provides premium factory equipment and a full line of architectural metal roofing and siding products, continuing its industry innovation legacy.

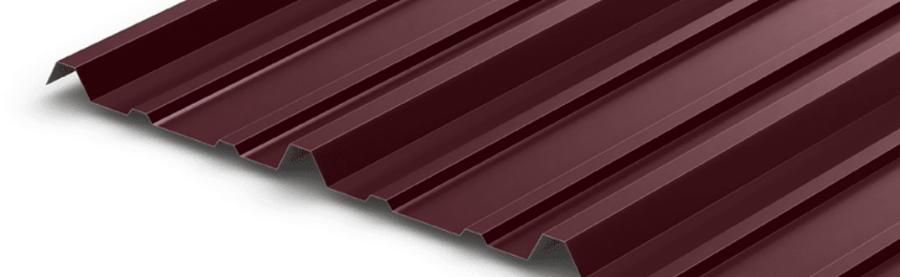

"R" Panel

The Berridge "R" Panel is an exposed fastener panel system offering broad 36" and 38-1/4" coverage options for vertical and horizontal applications. Available in 24- and 22-gauge steel options, as well as a 0.032-inch aluminum variant, this versatile panel can be utilized for various construction elements, including roofing, walls, soffits, ceilings, fascias, mansards, sheathing, and screen walls, making it an excellent choice for diverse project requirements. It boasts a smooth corrugated finish with visible fasteners, creating a distinctive pattern that sets it apart. One of the key advantages of the "R" Panel is its availability in continuous lengths up to 40 feet, enabling seamless installations. The "R" Panel incorporates foam closures, expandable foam filler tape, and mastic sealant tape to enhance weather resistance and overall performance. The panel system has undergone rigorous testing and certification processes, ensuring compliance with industry standards for fire performance, impact resistance, and uplift resistance. Additionally, it holds Florida Product Approval, demonstrating its ability to meet stringent structural requirements in hurricane-prone regions. See the Snow Guards Compatibility Chart for Berridge Manufacturing R Panel Screw Down Metal Roofing Panels.

R-Panels offer great flexibility when it comes to mounting snow guards. They can accommodate a wide range of snow guard models and styles, including screw-down options like SnoBar, ColorBar, SnoCleat PBR, and stainless steel SnowCatchers in designs such as Standard, Fleur-de-lis, Sun Burst, Maple Leaf, Mustang, and Kodiak. Most polycarbonate snow guards, except for Snojax I, can be attached using adhesives or mechanical fasteners. It's important to note that Snojax I requires mechanical fasteners for installation. When working with polycarbonate models, you must use the Surebond SB-190 adhesive, specifically designed for compatibility with these materials. You cannot use this adhesive with metal pad-style snow guards. For optimal installation, you should place smaller snow guards between the minor ribs, centering them on the panels. Some models, like Snojax II and Icejax II, require off-center mounting, straddling the left or right minor corrugation. Consistent placement over the same minor rib is crucial. Avoid attaching individual snow guards or rail systems directly to the panel's high ribs. The recommended installation method is to fasten snow guards by driving screws through the panel's low valleys and into a sturdy underlying structure. This technique ensures maximum installation strength and stability.

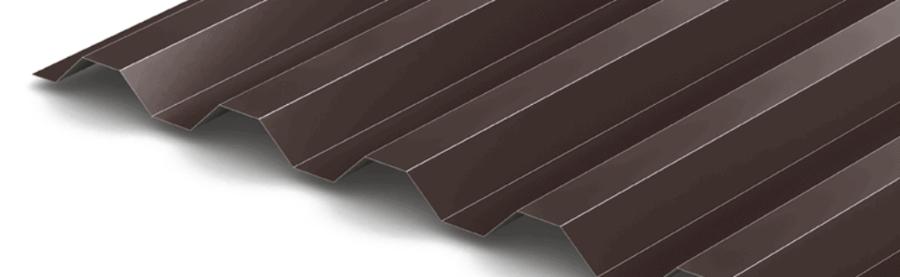

Double-Rib Panel

Berridge's Double-Rib Panel is a versatile, cost-effective metal roofing system designed for vertical applications over solid sheathing. This exposed fastener panel features a distinctive double-rib seam overlap, lending a traditional and appealing aesthetic suitable for residential and utility projects. Crafted from durable 24-gauge steel, the Double-Rib Panel features a smooth finish and a generous 24-inch coverage width. One of its standout advantages is the availability of continuous lengths up to 40 feet, streamlining the installation process. The Double-Rib Panel incorporates rubber closures at ridges, eaves, and headwalls to prevent air infiltration and enhance weatherproofing. Contractors employ expandable foam filler tape at hips and valleys. Contractors utilize mastic sealant tape at panel end laps, side laps, skylights, and in conjunction with foam closures. With its durability, classic aesthetics, and cost-effectiveness, the Double-Rib Panel from Berridge is an excellent choice for vertical roofing projects over solid sheathing, offering a robust and economical solution for residential and utility applications. See the Snow Guards Compatibility Chart for Berridge Manufacturing Double Rib Panel Screw Down Metal Roofing Panels.

One of the Double-Rib Panel's key advantages is its compatibility with various snow retention solutions. Customers can choose from metal screw-down individual pad-style snow guards, like the stainless steel SnowCatchers in Standard, Sun Burst, Maple Leaf, Fleur-de-lis, Kodiak, and Mustang shapes. It also works with all polycarbonate pad-style snow guards, including the SnoBlox Deuce, Icejax II, and SnoBlox Ace. You can install these polycarbonate models with screws or glue, depending on how much snow and ice retention you require. The Snojax I polycarbonate snow guard is the only exception, requiring mechanical fasteners due to its incompatibility with adhesive. For those who want to let snow and ice shed from their roofs while slowing it down and breaking it into smaller, safer pieces, the SnowBreaker and SnowBreaker 3M products are good options. On the other hand, if you're looking for a sleek, modern snow retention system or live in an area with heavy snow loads, you might prefer the SnoBar and ColorBar snow rail systems. These heavy-duty snow fences use mechanically fastened Tall ColorBrackets with butyl tape gaskets for a secure installation.

Deep-Deck Panel

The Deep-Deck Panel by Berridge is a versatile and durable corrugated panel system designed for various applications, including roofing, walls, soffits, ceilings, fascias, sheathing, and screen walls. Available in either 24 or 22-gauge steel or 0.032 and 0.040 aluminum construction, this pre-finished panel boasts a distinctive 7.2-inch rib spacing and a generous 36-inch coverage width, offering structural integrity and design flexibility. Its smooth corrugated finish can be installed horizontally or vertically, seamlessly integrating with open framing or solid sheathing substrates. One of the standout features of the Deep-Deck Panel is its availability in continuous lengths up to 40 feet, streamlining the installation process. The panel incorporates innovative features like deep deck rubber closures and expandable foam filler tape to enhance air infiltration resistance. Rigorously tested for wind and water resistance and meeting ASTM standards, the Deep-Deck Panel has earned the prestigious listing from the Texas Department of Insurance, ensuring its compliance with stringent building codes and performance requirements. See the Snow Guards Compatibility Chart for Berridge Manufacturing Deep-Deck Panel Screw Down Metal Roofing Panels.

The Deep-Deck Panel offers versatile integration with multiple snow retention solutions to handle snow and ice on your roof effectively. The polycarbonate SnoBlox Deuce acts as a pad-style guard, allowing you to retain snow and ice on the roof surface. The SnowBreaker and SnowBreaker 3M play crucial roles by breaking the ice and snow into more manageable and safer pieces while it sheds from the roof. These polycarbonate snow guards install using screws or adhesive. Additionally, the SnowBreaker 3M variant offers the convenience of 3M double-sided tape for secure attachment when conditions for Surebond SB-190 attachment are unavailable. The Deep-Deck Panel is compatible with the galvanized or stainless steel SnoBar and aluminum ColorBar snow rail systems. These systems use the 1.5-inch wide aluminum Tall ColorBracket for secure attachment, providing an effective snow management solution for your roof.

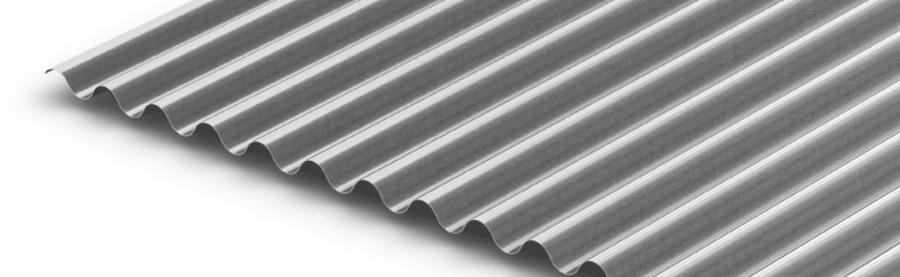

S-Deck Panel

The S-Deck Panel by Berridge is a wavy corrugated structural metal panel available in two coverage options: 32" and 34 2/3". Customers can choose between 22 and 24-gauge steel or 0.032 and 0.040 aluminum as the substrate, ensuring durability and longevity. This panel system can be mounted horizontally and vertically. The S-Deck Panel works well for roofs, walls, soffits, ceilings, fascias, sheathing, and screen walls. One of this panel system's standout features is its factory-curved ability, making it an ideal choice for covered walkways, shelters, and other curved architectural elements. The smooth corrugated finish adds a sleek and modern aesthetic. At the same time, the structural properties allow customers to use it as sheathing. The system incorporates foam closures, expandable foam filler tape, and mastic sealant tape to ensure optimal performance and prevent air infiltration. Available in continuous lengths up to 40 feet, the S-Deck Panel offers cost-effectiveness, versatility, and the ability to accommodate curved designs, making it a comprehensive solution for many architectural projects. See the Snow Guards Compatibility Chart for Berridge Manufacturing S-Deck Panel Screw Down Metal Roofing Panels.

The S-Deck Corrugated Panel boasts a wavy, corrugated pattern. This design allows for the mounting of snow guards on the panel's elevated ridges, deviating from typical installation guidelines. The S-Deck Corrugated Panel accommodates a few options for customers seeking snow retention solutions. One recent offering is the SnoCleat 2.67 snow guards, which can be securely fastened to the panel's high ribs using 3-inch screws. Alternatively, customers can opt for the SnoBar or ColorBar snow retention systems, which utilize the same ColorBracket 2.67 as the SnoCleat 2.67. Each ColorBracket 2.67 features six attachment holes, providing customers with the flexibility to use all six screws for enhanced mounting strength, particularly in regions prone to extreme weather conditions. While only four screws per bracket are required, the additional holes offer the option for increased stability and security. Pad-style snow guards are typically not recommended for curved roofs because they require a perfectly flat surface for proper installation. Snow rail systems are usually the correct product to use in these situations. Sometimes, when the roof's radius is shallow, our brackets may still be compatible. Complete a test fit before placing a full-system order. If you need clarification on the fitment of snow guards for your roof, contact the roofing manufacturer for their snow retention recommendations.

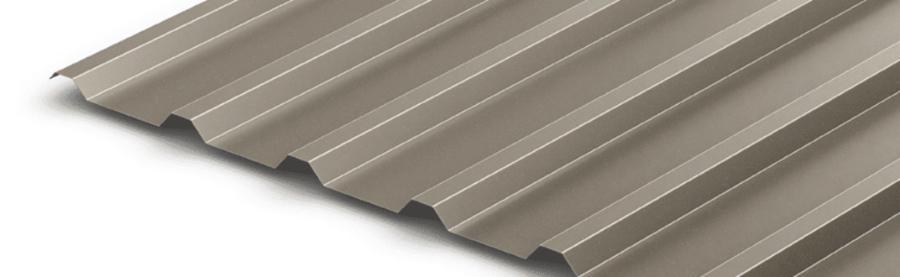

"M" Panel

The "M" Panel by Berridge Manufacturing is a versatile and cost-effective exposed fastener panel system. With generous coverage options of 36" and 38-1/4", it is compatible with vertical and horizontal applications such as roofing, walling, soffits, ceilings, fascias, mansards, and screen walls. Its smooth corrugated finish and exposed fasteners facilitate easy installation, while its durable 24 and 22-gauge steel or 0.032 aluminum construction ensures strength and longevity. The "M" Panel is available in continuous lengths up to 40 feet for efficient installation. The panel system incorporates air infiltration prevention measures, including inside and outside foam closures, expandable foam filler tape, and mastic sealant tape at strategic locations. This combination of design flexibility, economic efficiency, and structural integrity makes the Berridge "M" Panel an attractive choice for various architectural projects. See the Snow Guards Compatibility Chart for Berridge Manufacturing M Panel Screw Down Metal Roofing Panels.

The versatile "M" Panel can be combined with several snow retention products to control snow and ice on your rooftop effectively. The polycarbonate SnoBlox Deuce, SnoBlox Ace, and Icejax I models allow you to retain snow and ice on the roof surface. Simultaneously, the SnowBreaker and SnowBreaker 3M play crucial roles by breaking the accumulated ice and snow into more manageable and safer fragments as they shed from the roof. These snow guards mount using screws or adhesive, and the SnowBreaker 3M variant offers the convenience of 3M double-sided tape for secure attachment in areas where glue-down installation is not possible. The "M" Panel is compatible with the galvanized SnoBar and aluminum ColorBar snow rail systems. Both systems utilize the same 1.5-inch wide aluminum Tall ColorBracket for secure attachment, providing a comprehensive and effective solution for managing snow and ice on your roof.

Berridge Compatibility Chart for Snow Guards

| R-Panel Profile | Double-Rib Profile | Deep-Deck Profile | S-Deck Profile | M-Panel Profile | |

|---|---|---|---|---|---|

| IceJax I Screw Down | YES | YES | NO | NO | YES |

| IceJax I Glue Down | YES | YES | NO | NO | YES |

| IceJax II Screw Down | YES | YES | NO | NO | NO |

| IceJax II Glue Down | YES | YES | NO | NO | NO |

| SnoBlox Deuce Screw Down | YES | YES | YES | NO | YES |

| SnoBlox Deuce Glue Down | YES | YES | YES | NO | YES |

| SnoBlox Ace Screw Down | YES | YES | NO | NO | YES |

| SnoBlox Ace Glue Down | YES | YES | NO | NO | YES |

| Snojax I Screw Down | YES | YES | NO | NO | NO |

| Snojax II Screw Down | YES | YES | NO | NO | NO |

| Snojax II Glue Down | YES | YES | NO | NO | NO |

| SnowBreaker 3M | YES | YES | YES | NO | YES |

| SnowBreaker Screw Down | YES | YES | YES | NO | YES |

| SnowBreaker Glue Down | YES | YES | YES | NO | YES |

| SnowCatcher | YES | YES | NO | NO | NO |

| Decorative SnowCatcher | YES | YES | NO | NO | NO |

| SnoCleat PBR | YES | YES | NO | NO | NO |

| SnoCleat 2.67 | NO | YES | NO | YES | NO |

| SnoBar PBR | YES | YES | YES | NO | YES |

| ColorBar PBR | YES | YES | YES | NO | YES |

| SnoBar 2.67 | NO | YES | NO | YES | NO |

| ColorBar 2.67 | NO | YES | NO | YES | NO |

Before Adding Snow Guards to Your Metal Roof

1. Plan the Layout Right

Follow the manufacturer's recommended layout, regardless of your snow retention system. Our website provides free product spacing charts and quote request forms for custom layouts. Avoid putting snow guards in isolated areas like above doors, HVAC units, or chimneys.

2. Timing Adhesive Installation

You can install screw-down snow guards and rails anytime there isn't snow, ice, or debris on your roof. For adhesive-mounted guards, however, timing is vital. Our SureBond SB-190 adhesive for polycarbonate guards needs around 28 days at 50°F to cure fully. Late spring or early summer is best for most of the U.S. and Canada. Colder temperatures will pause the curing process until it warms back up. Rain won't affect it after 24 hours. However, avoid using SB-190 on copper roofs; the adhesive and metal may react.

3. Color Matching

You've got options to match our metal snow guards to your roof! The SnoCleat PBR, SnoCleat 2.67, and ColorBar Rails are compatible with slide-in color strips you can buy or make from leftover roofing material. We also offer powder coating in custom colors for a seamless look, which takes approximately 3 to 4 weeks. If you need it faster or want more color control, you can powder coat or paint the guards locally after delivery.

4. Securing Snow Guards to the Structure

When screwing in guards, make sure you're going into at least 1" of wood structure—decking, purlins, or added blocking. Fasten to the metal purlins when possible for pre-engineered buildings. Never screw into only the panels; that's asking for trouble. If you can't easily add blocking and your ground snow load is 45 psf or less, switch to adhesive-mounted snow guards instead.

5. Know Your Ground Snow Load

Ground Snow Load is the maximum snow weight your roof can handle. You can find this information online, check your building plans, or ask local officials for your area's number. Under 45 psf, you can use adhesive or screw-mounted individual guards and bars. Over that, we suggest snow rail systems.

6. Prevent Leaks

Products like SnoCleat PBR, SnoCleat 2.67, SnowCatchers, and screw-down rails come with butyl gaskets that seal without liquid sealant when used with our Master Gripper/Driller screws with neoprene washers. Some customers use an additional bead silicone sealant for peace of mind. For polycarbonate guards, use neutral cure silicone to seal the whole base, letting it ooze out the edges before smoothing with a gloved finger. We recommend NovaFlex MR150 sealant.

In Conclusion

Look out for more brand-specific content coming soon! Working with a company that quickly answers your questions and guides you is critical. At SnoBlox-Snojax, we pride ourselves on our full support every step of the way. Reach out anytime at support@snojax.com or 1-800-766-5291. Our Snow Guard Buyer's Guide and "What Works and Doesn't" page also contain helpful information. We're here to ensure you get the perfect snow guards and make the process smooth.

Do you have a metal roof from a different manufacturer?

Visit our "Snow Guard Compatibility by Roof Manufacturer" resource page for detailed information on which snow guards and snow retention systems are compatible with your metal roof.

Disclaimer

The views, recommendations, and information presented in this blog are solely those of the author and do not necessarily reflect the opinions or positions of the featured panel manufacturer, its brands, subsidiaries, or parent companies. Customers are strongly encouraged to reach out directly to the roof panel manufacturer for inquiries regarding snow guard compatibility with their products, as well as to address any potential warranty issues that may arise following the installation of our products.