-

-

-

-

-

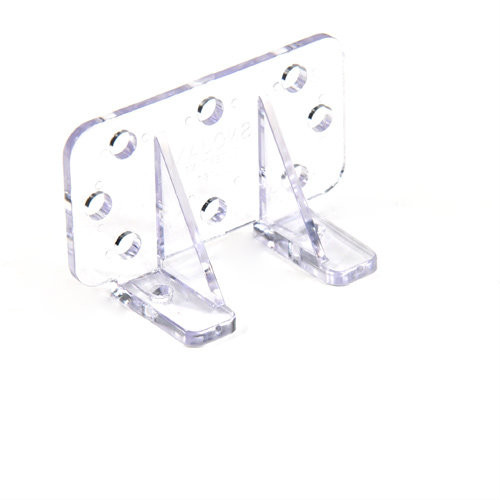

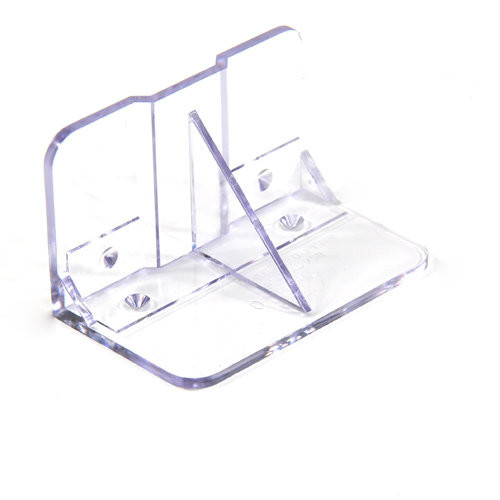

SnoBlox-Snojax

Icejax II Adhesive-Mounted Large Snow Guards 20 Piece Bundle

Was: $105.00Now: $99.00 -

-

-

-

-

-

-

-

-

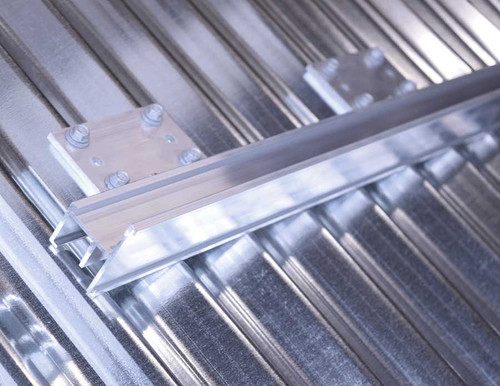

SnoBar-ColorBar

2 Bar ColorBar Mill Aluminum Snow Rails for Standing Seam Metal Roofs (6 Foot)

$239.00 - $285.00 -

-

SnoBar-ColorBar

SnoBar Galvanized Snow Rails for Standing Seam Metal Roofs (6 Foot)

$131.00 - $179.00 -

-

-

-

-

-

-

-

-

-

-

-

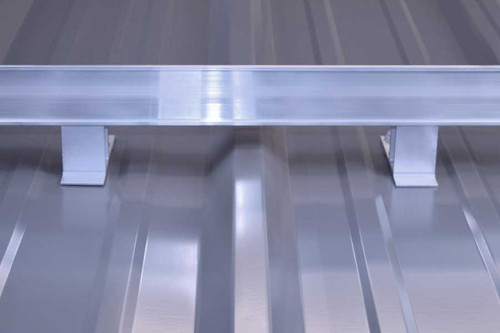

SnoBar-ColorBar

RCB-3 Mill SnoBar for Bulb and T-Seam Concealed Fastener Metal Roofs(6 Foot)

$155.00 - $221.00 -

-

-

SnoBar-ColorBar

RCB-3 ColorBar Aluminum Snow Rails for Bulb & T-Seam Standing Seam Metal Roofs (6 Foot)

$161.00 - $227.00 -

-

-

-

SnoBar-ColorBar

Screw Down ColorBar Snow Rails for 2.67 Corrugated Wavy Metal Roof (6 Foot )

$155.00 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Metal Roof Snow Guard Frequently Asked Questions (FAQs)

If you have a building or home with a pitched metal roof, made of steel, copper, or aluminum, and you live in an area that experiences winter weather, it's wise to consider adding snow guards or snow rails. Without them, you could encounter problems during the winter months, such as sudden slides of snow that might put people, pets, or property in danger. To prevent these risks and manage the hazards of snow accumulation, it's important to use the right snow guard solutions and seek expert advice.

Across most regions in the United States, building codes typically do not mandate the installation of snow guards. However, there are certain areas, especially those that experience significant snowfall or have particular roof characteristics, where specific rules or suggestions regarding snow guards may exist. The main purpose of snow guards is to enhance safety and protect property by stopping large amounts of snow and ice from sliding off roofs and potentially causing harm or damage below. Although building codes generally specify how builders should construct roofs to support the weight of accumulated snow, they seldom require builders to install snow guards themselves. Standards such as the International Building Code mainly address the roof's ability to bear snow loads rather than preventing snow from sliding. It is important to review the local building codes in your area to determine if snow retention measures are necessary for your project.

Regarding mounting, we recommend using adhesive for our polycarbonate snow guards. This method is effective and reliable, as the glue etches itself into the plastic, ensuring maximum holding strength.

Our test results show that metal and polycarbonate have similar test results. Please see our test results page in the resources tab. Many times, the decision is more aesthetic than strength-based for our customers. Installers can adhesively mount only polycarbonate snow guards on standing seam roofs.

Only the SnowBreaker can be used with 3M double-sided tape. Because of its shape, it breaks up the snow and ice rather than holding it in place. Double-sided tape is never a recommended attachment method for snow guards whose intended purpose is to retain snow and ice on the roof surface. We consider 3M tape a temporary solution only for use with the SnowBreaker when weather conditions are unfavorable for the adhesive curing time.

Bar systems are a robust solution for any roofing project. They are the only recommended solution in locations where the ground snow load is more than 45psf. An adequately designed snow retention system will typically consist of multiple rows up the roof's slope, regardless of type. A snow rail system may require fewer rows but sometimes costs more than pad-style snow guards.